Pre-galanized EMT Conduit Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of EMT conduit:

UL1242/ANSI C80.6 Intermediate Metal Conduit

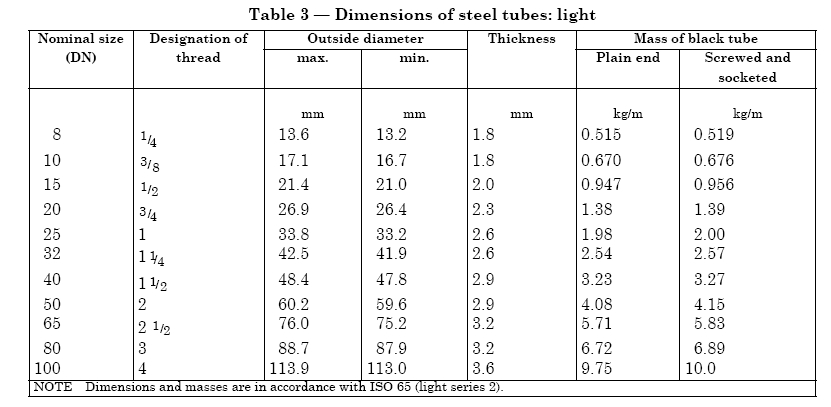

Size:

1/2"- 4".

Package:

With steel coupling & cap

Material:

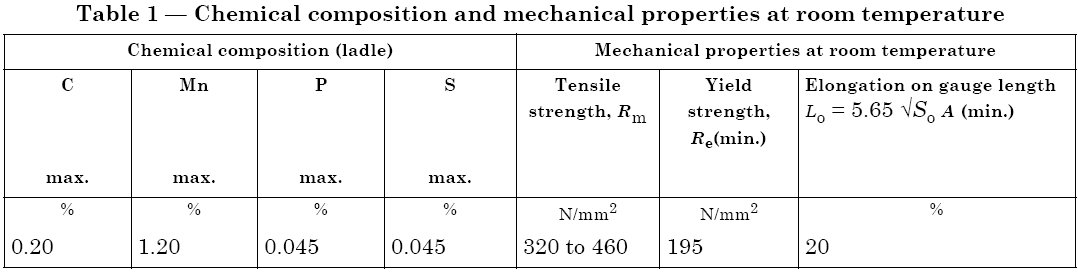

Q195 HIGH GRADE MILD STRIP STEEL

Intermediate Metal Conduit (IMC) is manufactured in accordance with:

>American National Standards for Steel. (ANSI C80.6)

>Underwriters Laboratories Standard for Electrical Metallic Tubing. (UL 1242).

Intermediate Metal Conduit (IMC) is threaded on both ends, one end is with a steel coupling, and the other end is with a plastic cap to protect the thread.

Surface:

Hot galvanized

Application of EMT conduit:

1 For low pressure liquid delivery such as water, gas and oil

2 For construction, e.g building greenhouse

Delivery of EMT conduit:30-50days

- Q:What are the different coatings used on steel pipes?

- There are several different coatings used on steel pipes, including but not limited to epoxy coatings, polyethylene coatings, zinc coatings, and galvanized coatings.

- Q:Can steel pipes be used for underground heating systems?

- Yes, steel pipes can be used for underground heating systems. Steel is a durable and robust material that can withstand the pressure and temperature requirements of heating systems. Additionally, steel pipes are resistant to corrosion, which is crucial for underground applications where exposure to moisture and other elements is common.

- Q:What is the maximum pressure that steel pipes can handle?

- The maximum pressure that steel pipes can handle varies depending on factors such as the specific grade of steel, diameter, and wall thickness of the pipe. However, steel pipes are known for their high strength and durability, and they can typically handle pressures ranging from a few hundred to several thousand pounds per square inch (psi).

- Q:Can steel pipes be used for brewery installations?

- Yes, steel pipes can be used for brewery installations. Steel pipes are often used in breweries for various applications such as transferring fluids, connecting equipment, and creating plumbing systems. Steel pipes are known for their durability, strength, and resistance to corrosion, which makes them suitable for handling the harsh conditions and high-pressure environments typically found in brewery installations. Additionally, steel pipes can be welded together, allowing for seamless connections, ensuring a reliable and leak-free operation. However, it is important to ensure that the steel pipes used in brewery installations meet the necessary standards and regulations to ensure the safety and quality of the beer production process.

- Q:What is the difference between hot-dipped galvanized and electro-galvanized steel pipes?

- Both hot-dipped galvanized and electro-galvanized steel pipes undergo a galvanization process to protect them from corrosion. However, there are distinct differences between the two methods. Hot-dipped galvanized steel pipes are immersed in molten zinc, resulting in a thick zinc coating on the steel's surface. This creates a durable and long-lasting barrier against corrosion. The thickness of the zinc coating varies, but it is generally thicker than that of electro-galvanized steel pipes. In contrast, electro-galvanized steel pipes are coated with a thin layer of zinc through an electroplating process. This involves passing an electric current through the pipes while they are submerged in a zinc solution. The zinc particles are then deposited onto the steel's surface, creating a thin and uniform protective layer. One key difference is the thickness of the zinc coating. Hot-dipped galvanized steel pipes have a thicker and more robust coating, making them suitable for harsh environments or exposure to corrosive materials. Another distinction is the appearance of the pipes. Hot-dipped galvanized steel pipes typically have a dull grayish finish, while electro-galvanized steel pipes have a smoother and more polished look. In terms of cost, electro-galvanized steel pipes are generally more economical because the electroplating process requires less labor and zinc. Ultimately, the choice between hot-dipped galvanized and electro-galvanized steel pipes depends on the specific application and desired level of corrosion resistance. Hot-dipped galvanized steel pipes are typically used in demanding environments, while electro-galvanized steel pipes are suitable for less corrosive applications where cost-efficiency is important.

- Q:How are steel pipes used in the construction of power transmission lines?

- Steel pipes are commonly used in the construction of power transmission lines as they provide a strong and durable structure to support the weight of the lines and withstand environmental conditions. These pipes serve as the main support structure for overhead power lines and are often used to elevate the lines above ground level or across bodies of water. Additionally, steel pipes are used to protect and encase underground power cables, ensuring their safety and longevity.

- Q:What is the weight of steel pipes?

- The weight of steel pipes can vary depending on their size, thickness, and length. However, on average, steel pipes can range from a few kilograms to several tons in weight.

- Q:How do steel pipes handle thermal expansion?

- Steel pipes handle thermal expansion by expanding and contracting with changes in temperature. The high thermal conductivity of steel allows it to transfer heat quickly, preventing excessive expansion. Additionally, the flexibility of steel allows it to absorb the expansion and contraction without compromising the integrity of the pipe.

- Q:How are steel pipes used in oil and gas industry?

- Steel pipes are extensively used in the oil and gas industry for various purposes such as drilling, transporting, and processing oil and gas. They are primarily used as casing pipes, which provide structural support and prevent the collapse of boreholes during drilling operations. Steel pipes are also used for transporting crude oil and natural gas from the wellhead to processing facilities or distribution points. Furthermore, they play a crucial role in the construction of pipelines for long-distance transportation of oil and gas, ensuring efficient and reliable delivery. Additionally, steel pipes are utilized in the construction of oil and gas refineries and petrochemical plants for various processes, including fluid transportation, heat exchange, and storage.

- Q:What is the hardness of steel pipes?

- The hardness of steel pipes varies depending on the specific grade and manufacturing process used. However, steel pipes are generally known for their high hardness and durability, as they are often designed to withstand heavy loads, abrasive environments, and high-pressure conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Pre-galanized EMT Conduit Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords