PPR Fitting Socket from China with High Quality Comply with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

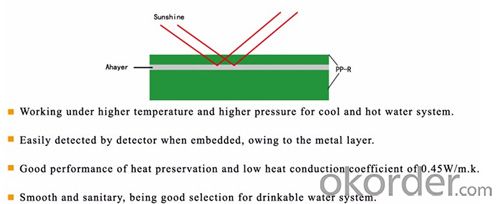

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

Chemical Structure of PPR

PP random copolymer of ethylene molecules generally contain 1 7% (by weight) and 99-93% (by weight) of propylene molecules. On the polymer chain, ethylene molecules randomly inserted in the middle of the propylene molecules. In such a random or statistical copolymers, the majority (typically 75%) are single molecules of ethylene incorporated into the insert, called the X3 group (three consecutive ethylene [CH2] are sequentially arranged in the main {TodayHot} chain), which can also be seen as an ethylene molecule is inserted in the middle of two propylene molecules.

Another 25% of the ethylene molecule is inserted more incorporated into the main chain, also known as X5 groups, since there are five consecutive methylene groups (two ethylene molecules together two propylene molecules inserted in the middle). It is difficult to distinguish between X5 and higher groups such as X7, X9 and so on. In view of this, the XS and higher ethylene content groups together counted as> X3%.

Randomness ratio X3 / X5 can be measured. When the above percentage X3 group is large, it will significantly reduce the crystallinity of the copolymer, the final properties of this random copolymer influence. Ethylene copolymer has very high levels of crystallinity of the polymer, similar to the effect when high random polypropylene content.

Unlike random copolymer PP homopolymer as the polymer backbone randomly inserted into the ethylene molecules hindered crystalline arrangement of polymer molecules. Copolymers of a decreased change in crystallinity caused by physical properties: PP homopolymer and random copolymer is reduced in rigidity as compared to improve impact resistance, better transparency. Ethylene copolymers also lower melting temperature, which has become in some ways the advantages of their use.

Random copolymer may contain more leather extract and random PP, as well as a much higher ethylene content of the polymer chain. This higher leather extract content may, depending on the polymerization process, to varying degrees in all the goods copolymer materials and meet the Federal Food Administration (FDA) on food contact {HotTag} specified on the cause difficult.

Manufacturing method of PPR pipes:

Ethylene / propylene random copolymer and ethylene molecules is carried out by polymerization of propylene molecules simultaneously obtained, the use of the reactor and the production of PP homopolymer same. Ethylene propylene molecular ratio of small molecules is faster than the reaction (reactive approximately ten times) propylene. This stereospecificity of the catalyst activity is increased and decreased, resulting in increased generation amount of atactic polypropylene. In order to reduce the generation of such random thereof, the reaction temperature needs to be reduced, thereby reducing the activity of the catalyst, and to reduce the content of the final product ppr sizes random isomer, to obtain a product having a more balanced performance.

Ethylene content (> 3%) random copolymer in the production process more difficult to deal with, it is difficult to carry out polymerization in hexane diluent, since the two by-products of the reaction (the amount of atactic polypropylene and ethylene-containing high copolymer) can be dissolved in hexane. This bulk liquid propylene polymerization reaction is the same, in spite of low solubility. Diluted with hexane to produce a large number of process by-product, it must be separated out in hexane in the recycle phase, which will increase the total cost of production, but was able to get close sparingly soluble polymer component of the cleaner. In the bulk polymerization process, these impurities will remain in the polymer, and trouble in handling sheet-like material. Moreover, the final copolymer products contain more soluble impurities. Second washing with an organic solvent, most of the impurities can be removed, but will increase the overall cost of production of the copolymer. In general, a high content of by-products, the flake random copolymer will become more viscous, when the ethylene content higher than 3.5% (by weight), the problem is more prominent.

- Q:Can plastic tubes be customized with color?

- Yes, plastic tubes can be customized with color. They can be manufactured in various colors to suit specific preferences or branding requirements.

- Q:Can plastic tubes be used for electric wire protection in outdoor applications?

- Yes, plastic tubes can be used for electric wire protection in outdoor applications. Plastic tubing is commonly chosen as a protective solution due to its durability, resistance to weather conditions, and ability to provide insulation for electric wires. It offers protection against moisture, UV rays, and physical damage, making it a suitable choice for outdoor environments where wires may be exposed to various elements.

- Q:How does using a plastic tube instead of a rubber tube affect the rate at which water flows through it?

- Rubber has a rougher texture, so there is more friction. Rubber wets and plastic doesn't, so there is more viscosity due to adhesion. Those effects reduce the flow rate for a given pressure.

- Q:anyone know of tube shaped bellows? I'm also interested in large plastic pipe that is like bellows.

- Try plastic dryer vent pipe. Its spiral wire with some kind of mylar like skin. It can be used as bellows. Right around 4 diameter.

- Q:What kinds of plastic pipes are available? Which ones are free to deform and turn?! At the same time can bear the pressure of tap water!

- General purpose thermoplastic plastic, its continuous use temperature below 100 degrees Celsius, polyethylene, polyvinyl chloride, polypropylene, polystyrene and called the four major plastic. Thermoplastic plastics are divided into hydrocarbons, polar genes of vinyl, engineering, cellulose and other types. Become soft when heated, harden when cooled, soften and harden repeatedly, and maintain a definite shape.

- Q:how do you get 2 pieces of plastic tube unstuck?

- Are they PVC? Is there a joint or fitting over them (a bigger piece of PVC that both tubes fit into)? Did someone else assemble it (or did you assemble it with a PVC glue)? If you answered yes to all three of these, you are in trouble. PVC is often assembled with glues which can be very difficult or impossible to undo. It is often easier to just cut the PVC and then extend it with a new joint.

- Q:I am on home oxygen and my air hose keeps kinking up. How do I stop that?

- Since this could be a Life Threatening Situation you should speak to your Doctor and the supplier of your Medical Oxygen equipment BEFORE changing anything. They have experience with YOUR situation and can make suggestions accordingly. If you do not Twist or Severely Bend the tubing by over tensioning it, as would happen if you pulled on it when it became taught, it likely should not be kinking. Therefore try to adjust how you treat the tubing in those situations to avoid that problem in the future. Alternately, if the strain is caused by a length of tubing that is too short thus restricting your movements to the point of kinking, a slightly longer piece of tubing might be in order. (CONSULT your Doctor about the appropriateness BEFORE changing the length of the tubing.) In the case of many of the clear plastic tubings, a given size (I.D. / Inside Diameter) is available with more than one Wall Thickness. A Thicker Wall will make the tubing less likely to kink or crush out of shape, but will be stiffer and heavier.

- Q:How do plastic tubes compare to aluminum tubes in terms of weight?

- Plastic tubes are generally lighter than aluminum tubes.

- Q:What are the advantages of using plastic tubes in the pharmaceutical packaging industry?

- There are several advantages of using plastic tubes in the pharmaceutical packaging industry. Firstly, plastic tubes provide excellent protection against moisture, light, and oxygen, ensuring the stability and integrity of pharmaceutical products. Secondly, plastic tubes are lightweight and portable, making them convenient for patients to carry and use. Additionally, plastic tubes are easy to squeeze and dispense the correct dosage, enhancing patient compliance. Furthermore, plastic tubes can be produced in various sizes and shapes, allowing for flexible packaging options. Lastly, plastic tubes are cost-effective and can be easily mass-produced, making them a cost-efficient choice for pharmaceutical companies.

- Q:looking for a place that sells plastic tubes to store wine, easliy stackable thanks

- Any beer and wine making shop will have EXACTLY what you need

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Fitting Socket from China with High Quality Comply with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords