powder coated perforated aluminum sheets plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

powder coated perforated aluminum sheets plates

Brief Introduction

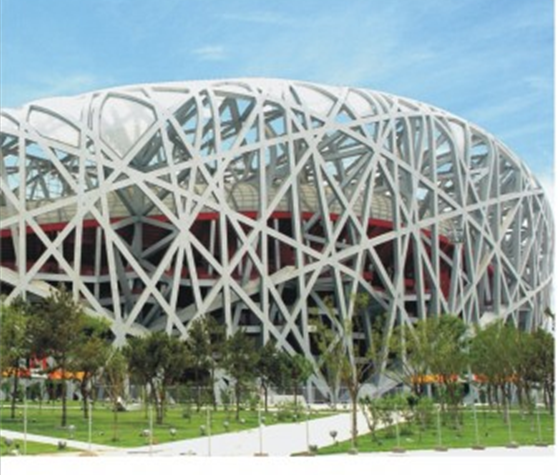

Aluminum Solid Panel is a kind of decoration material scribbled on its surface with fluorine carbon coating and used in cladding.and We are the supplier of 2008 Beijing Olympic Games,16th Asian Games, Guangzhou Baiyun Airport & Guangzhou South Railway Station

1.Characteristics

1) Well weather-resistance and anti-corrosion, high rigidity, easy for maintenance, only neutral cleanser and water needed for its self-clean performance;

2) Easy finishing with conventional working tools. Short time needs for project;

3) Good workability and light weight;

4) High impact-resistance, superior surface flatness, rigid;

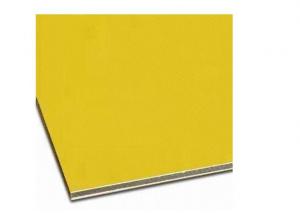

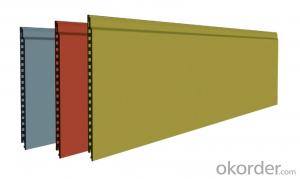

5) Various colors are available according your needs;

6) best price and quick delivery.

2.Applications

1) Exterior applications such as: wall cladding, facades, roofs and canopies, tunnels,

column covers or renovations

2) Interior applications such as: wall cladding, ceilings, bathrooms, kitchens and

balconies

3) Advertisement and market applications such as: display platforms, signboards,

fascias and shop fronts

4) Transport and industry application

3.Colors available:

(1).For general colors, please refer to our ACP color chart

(2).Customized color, please note the following

a. Provide a sample color: better to be a color painted on metal base in order to prevent color difference

b. If you know the factory color code or international standard color code, just provide us with those code number. This could be the quickest and most precise method

c. Normally it will take 1 week for us to counter-provide our color samples for you to compare and confirm by the co-work of our painting experts and the paint suppliers.

d. After receiving our counter-samples, pls. confirm to us as quick as possible on in order for us to set out for production accordingly.

4.Raw Meterials

1.Aluminum alloy:AA1100,AA5052,AA3003 or upon request.

2.Surfce coating:PPG,Akzo Nobel and Nipon,Becker.

3.Shape:Upon on request,including flat,arc,bow and other special shapes.

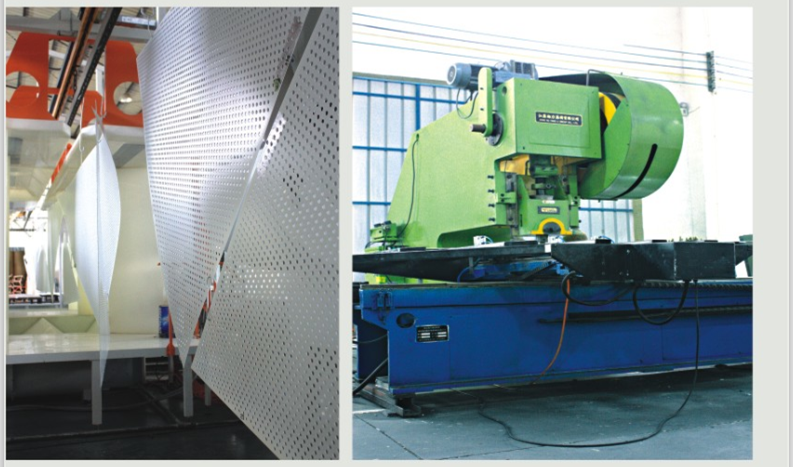

4.Perforation:Different patterns as requirements,we have CNC machine.

5.Specifications

a.Thickness:2.0mm,2.5mm,3.0mm,3.5mm,4.0mm

b.Max Size:1,600mm*4,500mm(Flat)

6.Features

1.Light weight,high strength and rigidity

2.Excellent weather resistance and anti-corrosion

3.Good processing capacity,able to be shaped into flat,arc,globe,ect.

4.Various colors ,good decoration effects

5.Easy to be cleaned and maintained

6.Easy and quick in installation

7.Envirnmental-friendly,able to be recycled

7.production process

1.Project design 2.Cellular drawing 3.Work out procedures 4.Plate check 5.Plate blanking 6.Contour and punch 7.Pressure bend 8.Abnormal shape machining 9.angling & sealing weld 10.Rim angle trimming & loader installation 11.Stud welding reinforcement 12.Surface polish 13. Drug test 14.Clean & chromium 15.Electrostatic spray 16.Quality inspection 17.Film pasting & Packing

8.spraying process

1st coat option:Color top coating

2nd coat option:Base primer+color top coating

3rd coat option:Base primer+Color top coating+top clear coating(protecting paint)

4th coat option:Base primer+Color top coating+Separation coating+Color top coating +top clear coating(protecting paint)

9.Aluminum Alloy guide

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Other | Remain |

| 1100 | 0.4 | 0.55 | 0.05-0.2 | 0.05 | ... | 0.01 | ... | ... | 0.15 | 99 |

| 3003 | 0.6 | 7 | 0.05-0.2 | 1.0-1.5 | ... | 0.01 | .... | ... | 0.15 | aluminum |

10.Dimension avaible

Alloy | 1100,3003 |

Temper | All tempers Subject to alloy |

Thickness | 1.0-6mm for mill finish ,subject to different project |

Width | Subject to customers option,maximun 1.5 meters |

Length | Subject to customers option,maximum 6 meters |

11.Finish introduction:

| Mill finish | Finish of aluminum itself,with a natural anodic layer formed in the air,week corrosion resistance | ||||||||

| Powder coating | The powdered paint is electrostatically charged and sprayed onto the part,to form a thick layer to protect the surface.with very good corrosion resistance | ||||||||

Brand:Guangmei

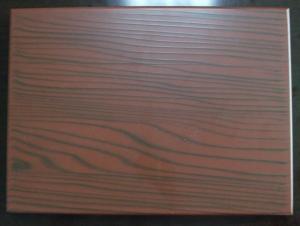

Yellow color Aluminum solid panel,Curtain wall aluminum panel

Aluminum solid panel design

- Q:Curtain wall area of 450 square and less than 24 meters, may I ask only three test?

- Therefore, unless the inspection agency and the owner asked to do the four test, or can only do the three tests can be, that curtain wall wind pressure deformation performance, rain leakage performance, air permeability of the three test

- Q:My shower curtain is pink with white flamingos on it. So what kind of walls would go good with that? I dont want white...and i dont think my family will allow black.any decorating/design ideas?

- depends...when I was single I used to have a pink and black bathroom it was so girly cute and fun ... but chocolate brown and pink can be really cute too!! also u can go online and look at store and what they have for bathroom sets and get ideas of what u can do

- Q:i want its colour be happy and suit.

- What colour are the rest of the things in the room? I would say a medium gray will be good....

- Q:I was doing curtain wall construction, would like to ask the next approach to the need to prepare what entry information ah. For example, what started the report ah, construction organization design ah what.

- Company qualification information, personnel approach plan, construction plan and so on.

- Q:Glass curtain wall dry hanging stone and glass curtain wall generally away from the wall how far?

- Conventional curtain walls are generally between 200 and 300 mm.

- Q:Curtain wall stone around the package window 50, cut the size of the window should be smaller around 50?

- Here you do not quite understand that the package window 50 refers to the left and right (or up and down) the total of 50, or about 50 (or up and down) a total of 100, I press the left and right (or up and down) a total of 50 to answer you: Windows need to install the operating space, the top side of the old experts to answer 10, this is feasible, but I think the best points in two, First, if the package edge stone has been installed, then you let the scene construction team technical staff on the edge of the stone hole after the actual size of the foot back to the measurement, and then take a minimum reduction of 2mm search Second, if not installed stone edge directly to the hole size by 5-8mm. Where the content Tingduo, the node if only the window owed in the stone hole is wrong, so that the window can only be fixed with a nail on the stone, likely to cause stone cracking. Should be selected in the civil hole on the first fixed channel, so that the windows fixed on the channel. Stone and then into the window frame 10mm, at the intersection to play sealant. If the windows do not have nails fixed directly into the edge of the hole to seal the seal, then no mechanical fixed way to have security risks. The last one is the outdoor stone directly on the window frame, the outdoor to fight the sealant. Indoor stone directly with the window frame do not fight the plastic, or indoor direct use of materials and window frames sealed.

- Q:Office glass curtain wall warranty period?

- Notice of the Ministry of Construction on Printing and Distributing the Interim Provisions on Strengthening the Management of Building Curtain Wall Works (Construction [1997] No. 167) Article 19 A building curtain wall project enterprise shall expressly commit to a warranty period of not less than three years for the construction curtain wall project in the contract signed with the construction project legal person. Warranty period due to the quality of the project costs incurred by the responsible party to pay.

- Q:My wall is a light brown cappuccino color, have a beige/creme sofa, purplish-bluish rug, loving the combi so far. Would like to add some blue curtains. Do you think the blue curtains would match fine?

- Blue curtains would match the colors of your wall. You will appreciate the colors in your room if the sunshine from the sun will come out in your window and will illuminate the whole place.

- Q:Curtain wall angle code and embedded parts need to be connected around the full weld

- But taking into account the scene of some factors, such as the quality and level of workers. General drawings will be marked full of welding. You calculate the weld is 100mm, his part of the site welding force may not be able to reach 100mm. So the drawings indicate the weld will be higher than the calculation of some.

- Q:a peep under the curtain wall analysis!! HELPPPP?

- Okay, I have an idea as to what this is and I'm gonna knock it out with my opinion. The wall is the Iron Curtain (coined by Winston Churchill). The man is looking under the wall, because he is curious of what lies beneath or beyond it. The man is running away from the wall, because he is terrified by what he sees: oppression, communism, deprivation, etc. The industry on the eastern side can be described as the social network of communism - the ownership of the factory and the people in it by the government. The tank on the eastern side represents two things: oppression and aggression. It's there as a symbol to remind the people of the East that the Red Army calls the shots and also to be a warning to those of the West that the Red Army is capable and can destroy you (it's a sign of military might). It explains the beginnings of the Cold war; the initial fear of communism and the U.S.S.R.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

powder coated perforated aluminum sheets plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords