Weed Barrier Fabric or Capped Woven Fabric for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

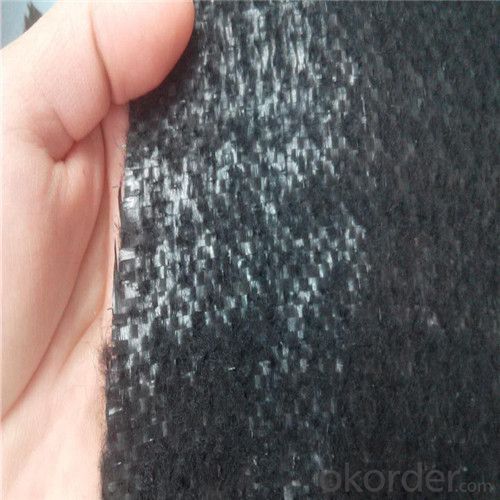

Weed Barrier Description

Weed barrier fabric is a kind of composite with woven and needle punched, made from polypropylene, and botanical component of pest control, which attempts to stop weeds, conserves soil moisture, increases growth.

Weed Barrier Fabric Specification

Weight: 120gsm-200gsm

Width:1m -6m

Length:as request

Color: white, black, green, as request

Strip: every 12", as request

Weed Barrier Fabric Property

1)UV treated

2)Under turf Chemical free

3)Effective weed control

4)Allows air, water and nutrients to reach the soil and the plant roots

5)Very resistant to puncture

6)Easy to install

7)Raises quantity and quality of crops

Weed Barrier Fabric Application

Used for Paths, Patios, Timber decking, Block paving, Soft landscaping and so on.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: A creek next to our property is eating away the embankment and an engineer suggested using the sand in the creek bed.. wrapping it up in geotextile fabric in the form of a burrito but he did mnot mention how to fasten them shut..any ideas or experience with erosion control out there?

- Get some tie wire or baling wire. It's a soft wire used for tying reinforcing steel together or for baling straw. You could also use plastic cable ties.

- Q: Geotextile detection sampling, how many meters

- Two meters by two meters! Geotextile manufacturers to answer!

- Q: What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as material type, weight, tensile strength, permeability, and durability. These specifications ensure that the geotextiles effectively prevent soil erosion, retain sediment, and allow for proper drainage in sediment control projects.

- Q: Are geotextiles commonly used in coastal erosion control?

- Yes, geotextiles are commonly used in coastal erosion control. They are often deployed as a protective measure to stabilize soil, prevent erosion, and enhance the overall stability of coastal areas. Geotextiles help to mitigate the impact of waves, tides, and currents by providing reinforcement and separating different soil layers. They are an effective and widely employed solution in coastal erosion control strategies.

- Q: How do geotextiles help in reducing soil erosion caused by wind?

- Geotextiles help in reducing soil erosion caused by wind by creating a barrier that prevents the soil from being lifted and carried away by strong winds. It acts as a protective layer by stabilizing the soil, preventing its displacement and preserving its integrity.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: How do geotextiles help in preventing weed growth?

- Geotextiles act as a physical barrier that prevents weed seeds from accessing sunlight and nutrients, inhibiting their growth and establishment. They also help in reducing soil erosion and maintaining the integrity of landscaping projects.

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- Some key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and strength of geotextile material, ensuring proper placement and anchoring of the geotextile, evaluating the stability and drainage requirements of the site, and considering the compatibility of the geotextile with other materials and construction methods used in the retrofitting project. Additionally, careful attention should be given to the design and installation of the geotextile to ensure it effectively enhances the overall stability and performance of the structure during seismic events.

- Q: Are geotextiles suitable for use in canal lining?

- Yes, geotextiles are suitable for use in canal lining. They are commonly used to reinforce and protect the canal lining from erosion, provide filtration, and improve drainage. Geotextiles offer durability, stability, and resistance to various environmental conditions, making them an effective solution for canal lining applications.

Send your message to us

Weed Barrier Fabric or Capped Woven Fabric for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords