Rotary/Round/Shaft Kiln Calcined Bauxite 86 Made in China for Refractory with Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Henan, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6< span=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | 80# 85# 86# 87# | Brand Name: | CNBM |

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

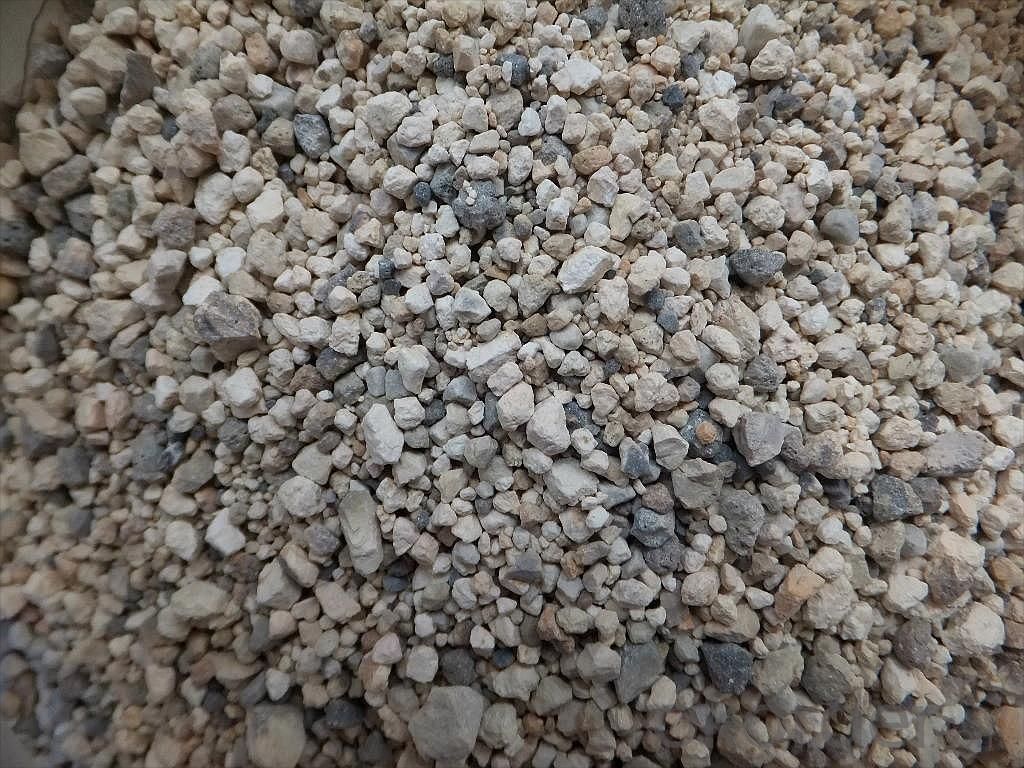

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

On July 7th, the US Fortune magazinepublishedthe 2014 Ranking List of World Top 500 Enterprises. China National Building Materials Group Corporation (CNBMGroup in short) enters into the Fortune Global 500 for the fourthsuccessive time withits operating revenue of 41.03 billion USD, ranking the 267th place, and rising 52 places over last year. Amongst the three building materials enterprises listed in the Fortune Global 500, CNBM ranks the second with promising momentum.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

We promise the best cargo and the best service!

- Q:What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q:What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q:How long is the fire endurance of the rock wool board?

- When the average temperature reaches 140 degrees Celsius or 180 degrees Celsius, it starts to lose the fire insulation function.

- Q:How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- Q:What does refractory mean?

- Ordinary refractories are often used brick, semisilica brick, clay brick, high alumina brick, magnesia brick etc..Special materials often use AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so onUnshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q:How to detect the acid resistance of refractory? Is there any standard? Thank you

- There is a standard. However, the range what you said is a little big, it's difficult for me to say. But though the scope is a bit big, it should be: You can check the industry standard network, to see whether you can check it.

- Q:What's the fire resistance rating of the exterior fire?retardant?coating?

- Current fireproofing material is mainly classified into five grades: A class: Incombustible building material which is almost incombustible. A1 class: It is noncombustible and cann't cause open fire. A2 class: It is noncombustible but needs to measure the smoke it will cause and that should be qualified. B1 class: Flame-retardant building materials: Good in fire retardation, it is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In the case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material has no fire retardation effect at all. It is highly combustible with big fire risk. Besides, the classifications of fire resistance rating of building materials are different according to different standards: dDIN4102: A1, A2, B1, B2, B3; x0dEN13501-1: A1, A2, B, C, D, E, F. Hope it helps.

- Q:What are the best refractory materials in 2,400 Celsius degree?

- and carbon fiber or nanomaterials.

- Q:what kind of fireproof materials is used for high rise buildings?

- First, fire resistance steel door: in the general real estate, developer uses more of fire resistance steel door. The mid-low-end doors are the earliest products and mostly widely used with longer servce time. The disadvantages are corrosions, thus it will rust, fade after being used for a while, and will affect the overall appearance. Styling lines are hard, not matching well with modern home decorative styles. Second, the stainless steel fire doors: anti-theft performance ,durable, stronger security. Compared to the general iron or mixed iron and steel security doors, stainless steel doors never rust and most importantly its uniqueness in addition to lasting bright color. Disadvantages: Stainless steel security doors are mostly silver, giving us dull feelings by seeing its appearance and color, lack of coordination. Third, glass fire door: high quality fire glass doors. recent years have seen wide application in office buildings and some high end public place, less in individual users. Compared to the current categories of timber, fire glass door is not only simple and luxury and durable.

- Q:What are grade classifications of the external walls for fireproofing?

- The basic level can be divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indicators to make specific division, but I partly cannot report for a while, because it is very professional and technical. Please contact Qingdao Shanfang Instrument Co., LTD for details, they specialized in the external wall thermal insulation materials fire?rating testers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rotary/Round/Shaft Kiln Calcined Bauxite 86 Made in China for Refractory with Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords