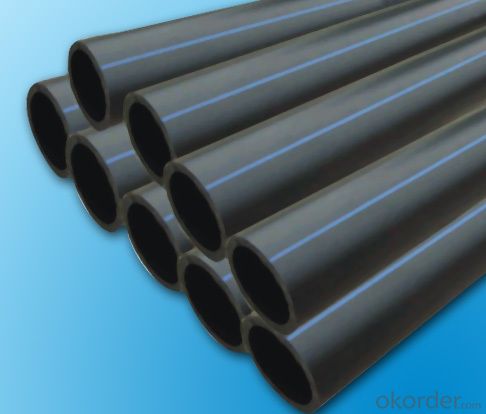

PE gas pipe manufacture H319

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. PE gas pipe manufacture (GB/T 15558-2003)

Quick Details

· Place of Origin: China (Mainland)

· Material: PE

· Specification: 20-630mm

· Length: 5.9/11.8M

· Standard: GB/T15558-2003

Packaging & Delivery

Packaging Details: | bundle or as your required |

Delivery Detail: | within 15 days after downpayment |

Specifications

PE gas pipe manufacture (GB/T 15558-2003)

1. OD:20-630mm

2. Standard: GB/T15558-2003

3. Quality with competitive price

PE GAS PIPE

Material: PE 100

Specification: 20mm-630mm

Length: 5.8m 11.8m per length

Thickness: 2.3mm~57.3mm

Standard: GB/15558, ISO4437

Color: black, yellow or black with yellow stripe or others

Feature:

**Long service life: PE pipe can be used safety for more than 50 years

**Excellent resistance to corrosion capability: It can endure the erosion of various kinds of chemical media, no electrochemical corrosion.

**Excellent transportation capability: the inner side of the PE pipe is smooth and has litter abrasion and resistance. The absolute roughness k=1.01mm and “k” will not change with time.

**Reliable joint capability: the intensity of the welded joint of PE pipes is above the pipe itself. The interface will not disconnect because of the moving of soil or the live load.

**Reliable safety capability: PE pipe has strong capability of anti-cracking and is not prone to crack.

**Better resistance to concussion capability: PE pipe possesses high toughness and can endure strong impact. Pressure of heavy things will not cause the pipe to break.

**Strong toughness: PE pipe is a kind of pipe that possesses high toughness whose breaking elongation rate generally exceeds 500% and has strong ability to adapt to the uneven settlement of the pipe bending.

**Excellent flexibility: PE pipe can be easy to change in accordance with the construction requirements. Small-diameter pipe is available to be supplied in coils.

**Installation cost lower: light weight, easy handling and installing, simple welding technique and exemption of being embalmed result in low construction cost.

Application:

gas distribution, environmental protection, and chemical industry etc.

2. PE PIPE MANUFACTURE (ISO 4427)

Quick Details

· Type: Other Plastic Building Materials

· Place of Origin: China (Mainland)

· Size: 16-1600mm

· Color: Black, blue

Packaging & Delivery

Packaging Details: | plastic bags or as your request |

Delivery Detail: | Within 25 days after receiving the payment |

Specifications

PE PIPE MANUFACTURE (ISO 4427)

A. Material: High quality PE80 or PE100

B. Diameter: 16 to 1600mm

C. Pressure:0.6-1.6Mpa

PE PIPE MANUFACTURE (ISO 4427)

Features:

**Sizes: 16 to 1600mm

**Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

**Colors: blue, black or other colors on request

**Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

**Standard: GB/T 13663, ISO 4427

**Certification: ISO9001, ISO14001

**Packaging: coils in plastic bag or as your request

Advantages:

**Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

**Corrosion Resistant: resist chemical matters or electron chemical corrosion

**Lower Installation Costs: light weight and ease of installation can reduce installation costs by

as much as 50% over metal piping system

**Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume

than metal pipe

**Longevity: more than 50 years under proper use

**Recycled and Environment-friendly

Application

water pipe network system, industrial liquids transportation, Agricultural irrigation pipe and sewage treatment

- Q:Plastic metal hose connector model specification, who knows?

- Package type plastic hose is many, the most common is the DPJ thread joint, DPN joint, DKJ card connector, DGJ self fixed joints, Glenn joints, fittings

- Q:Three yuan ethylene propylene rubber joint (high temperature resistant rubber joint) can withstand high temperature

- High temperature rubber joint adopts three yuan ethylene propylene rubber processing, can withstand high temperature 140 degrees, if need higher temperature, need to use fluorine rubber, the highest temperature can reach 200 degrees!

- Q:What are the types of hose connectors?

- Joint classification of common are: expansion joints, quick couplings, withhold joints, removable fittings, compression fittings, flared joint is in welded joints.

- Q:What is the difference between plastic lined steel pipe and rubber lined steel pipe?

- Common ground1. the same matrix: carbon steel tube2., similar structure: are lined pipe, steel, rubber (plastic) composite3., corrosion resistance is close to: in most acid and alkali medium environment, can work properly

- Q:What is the high and low pressure circuit of diesel engine?

- Low pressure oil circuit is the oil circuit from the tank to the diesel pump. The negative pressure is in the oil circuit, and the oil is drawn out with the diesel oil pump and is sucked into the diesel pump to pressurize. It's obvious that all the oil lines are rubber lines.

- Q:Flex rubber joint installation skills, what are the materials of rubber soft joint?

- Rubber soft joint material:Ordinary water, acid and alkali resistant, oil resistant rubber, high temperature resistance, low temperature resistance

- Q:What are the gas hoses?

- The stainless steel is expensive, 40 yuan set.The rubber is cheap, 10 yuan a set.Where do you come from? I don't know. In our Shanghai gas, this price includes the labor cost of the installation to you. In other words, fix it directly for you.

- Q:How often do the oil - resistant rubber pipes undergo atmospheric pressure testing?

- Bending test: after bending the hose to a certain extent, measure the minimum outside diameter of the bending part and the ratio of the outside diameter before bending, the passing capacity of the steel ball and the bending force when the tube is pressurized.

- Q:What glue can glue rubber tube?

- 1: clean: high temperature, quick drying glue, use dry cotton cloth or sand paper, then dust, oil, rust, etc., and then use the treatment agent or cleaning agent to clean, then clean the surface.2, sizing: flexibility speedglue unscrew the front cover, can be used as a glue bottle with cotton cloth to wipe clean and quick drying glue, can be set using needles or PE dropper, to control the flow of glue, ensure the bonding effect.

- Q:Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- Control the noise produced by parts of machinery, equipment, and equipment. The pump foundation of the new pump house should adopt heavy weight to prevent vibration from producing noise. Vibration isolation should be set up with rubber vibration isolating pads to reduce vibration noise. Each pump unit shall be provided with a foundation to prevent resonance. Use "soft" connection as far as possible in the suction pipe and pressure pipe of the pump. Periodic maintenance problems, such as packing leakage, equipment parts loose, serious wear and tear of equipment parts, mechanical vibration and so on, should be repaired in time, thereby reducing noise.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE gas pipe manufacture H319

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords