Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

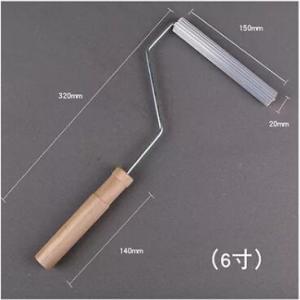

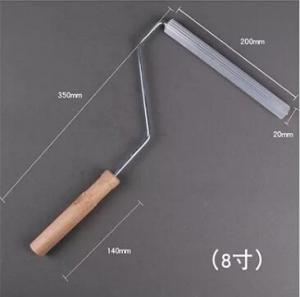

Paddle Laminating Roller

Product Description

Paddle Laminating Roller is widely used in the production of glass fiber reinforced plastic, and the inner surface of the bubble roller puncture, for removing air bubbles from lamination, leveling and compaction of resin coating to drive bubbles.

Technique Data

Type: | Roller Brush |

Handle: | Wooden and plastic |

Brush Material: | Aluminum |

Feature | Non-slip handle, multi-size, good material, high quality, durable |

Use | Remove air bubbles |

Color | Customized |

Size | 2‘’3‘’4‘’5‘’6‘’8‘’ |

MOQ | 100pcs |

Delivery Detail | About 15-20 days after having received the deposits. |

- Q:Is fiberglass chopped strand suitable for applications requiring UV resistance?

- No, fiberglass chopped strand is not suitable for applications requiring UV resistance. Fiberglass is known to degrade when exposed to UV radiation, leading to loss of strength and performance over time. For UV-resistant applications, alternative materials such as UV-stabilized plastics or additives can be considered.

- Q:How is fiberglass chopped strand used in the telecommunications industry?

- Fiberglass chopped strand is used in the telecommunications industry as a reinforcement material for various components such as cable jackets, connectors, and insulators. It enhances the strength, durability, and fire resistance of these telecommunications products, ensuring reliable and long-lasting performance. Additionally, fiberglass chopped strand helps to minimize signal interference and improve the overall efficiency of telecommunications networks.

- Q:Is fiberglass chopped strand suitable for automotive interior components?

- Indeed, automotive interior components can be made suitable by the use of fiberglass chopped strand. Fiberglass, a versatile material, provides numerous advantages for automotive purposes. It possesses qualities such as being lightweight, robust, and having exceptional dimensional stability. These characteristics render it a fitting selection for a wide array of interior components, including door panels, dashboards, trim panels, and seat backs. Superior mechanical properties are the reason why fiberglass chopped strand is commonly employed in automotive interior components. These chopped strands are blended with a resin matrix, resulting in a composite material that can be shaped into diverse forms. Consequently, this enables intricate designs and customization options, catering to specific requirements within the automotive industry. Moreover, fiberglass showcases resistance against high temperatures, chemicals, and UV radiation, which are essential factors in the automotive sector. It can withstand elevated temperatures while maintaining its structural integrity, and it also remains unaffected by sunlight or chemical exposure, preventing fading or discoloration. Additionally, fiberglass chopped strand proves to be an economical choice for automotive interior components. It provides a cost-effective solution without compromising quality or performance. Its durability ensures long-lasting functionality, minimizing the need for frequent replacements and maintenance. To conclude, fiberglass chopped strand is undoubtedly an appropriate option for automotive interior components. Its lightweight nature, strength, dimensional stability, resistance to heat and chemicals, and cost-effectiveness all contribute to making it an ideal choice for various automotive applications.

- Q:How does the fiber aspect ratio affect the performance of chopped strand composites?

- Determining the performance of chopped strand composites is greatly influenced by the fiber aspect ratio. The aspect ratio, which is the ratio of fiber length to fiber diameter, plays a crucial role in this regard. Typically, composites containing fibers with higher aspect ratios display improved mechanical properties. The inclusion of longer fibers ensures a more continuous reinforcement within the composite matrix, resulting in enhanced stiffness, strength, and fatigue resistance. This is due to the longer fibers creating a more efficient load transfer mechanism, which evenly distributes applied stress and prevents crack propagation. Moreover, fibers with higher aspect ratios provide superior interfacial bonding with the matrix material. This enhanced adhesion at the interface improves the efficiency of load transfer, reducing stress concentrations and minimizing the risk of delamination. Additionally, it enhances the overall toughness of the composite, making it more resilient to impacts and less susceptible to fiber pullout. However, the benefits of increasing aspect ratio have limitations. Beyond a certain point, longer fibers become more challenging to process and evenly disperse within the matrix. This can lead to fiber entanglement, clumping, or inadequate wetting, resulting in decreased mechanical properties and reduced composite performance. Furthermore, the aspect ratio can impact the manufacturing process of the composite. Fibers with higher aspect ratios may require more advanced processing techniques, such as injection molding or compression molding, to ensure proper alignment and distribution. On the other hand, shorter fibers with lower aspect ratios are often preferred for simpler manufacturing methods like hand lay-up or filament winding. In conclusion, the fiber aspect ratio has a significant impact on the performance of chopped strand composites. Higher aspect ratio fibers generally improve mechanical properties, interfacial bonding, and overall toughness. However, a careful balance must be struck between fiber length and diameter to achieve the desired performance characteristics, as exceeding the optimum aspect ratio range may pose processing challenges.

- Q:How does the fiber content affect the dimensional stability of fiberglass chopped strand composites?

- The fiber content in fiberglass chopped strand composites directly influences the dimensional stability of the material. Higher fiber content enhances the overall strength and stiffness of the composite, thereby minimizing dimensional changes and ensuring improved stability. Conversely, lower fiber content may result in reduced dimensional stability and increased susceptibility to deformation or warping under external forces. Overall, a higher fiber content provides better dimensional stability to fiberglass chopped strand composites.

- Q:Is fiberglass chopped strand suitable for high-temperature applications?

- No, fiberglass chopped strand is not suitable for high-temperature applications.

- Q:Can fiberglass chopped strand be used in the manufacturing of sports equipment?

- Sports equipment manufacturing can utilize fiberglass chopped strand, which is a versatile material offering numerous advantages. Firstly, its lightweight property enhances ease of use and maneuverability, making it ideal for tennis rackets, golf clubs, and hockey sticks. Secondly, its exceptional strength and durability enable the equipment to withstand the stress and impact it encounters during use, ensuring optimal performance over an extended period. Additionally, fiberglass chopped strand's corrosion-resistant nature safeguards against moisture and environmental factors, benefiting equipment exposed to water or harsh weather conditions like surfboards or kayaks. Moreover, its ability to be easily molded into various shapes and sizes allows for the customization of sports equipment, meeting the specific requirements of different sports and athletes. In conclusion, fiberglass chopped strand is a suitable material for sports equipment manufacturing, as it possesses lightweight, strength, durability, corrosion-resistance, and flexibility, enhancing performance and longevity, making it a popular choice in the industry.

- Q:What are the typical thermal expansion characteristics of chopped strand composites?

- The typical thermal expansion characteristics of chopped strand composites are that they exhibit a low coefficient of thermal expansion. This means that they expand very minimally when exposed to heat and contract when cooled, making them suitable for applications where dimensional stability is important.

- Q:How does the fiber length affect the flow behavior of chopped strand composites?

- The fiber length in chopped strand composites directly affects the flow behavior of the material. Longer fibers tend to align better during processing, leading to improved flow and reduced void formation. Shorter fibers, on the other hand, may result in poorer flow behavior and increased likelihood of agglomeration or uneven distribution throughout the composite.

- Q:How does the dispersion of fiberglass chopped strand affect its performance?

- The dispersion of fiberglass chopped strand significantly affects its performance. A well-dispersed chopped strand ensures better strength, stiffness, and overall mechanical properties of the final composite product. It allows for improved bonding with the matrix material, leading to enhanced load transfer and resistance to cracks or delamination. On the other hand, poor dispersion can result in weak interfacial adhesion, reduced mechanical strength, and compromised durability of the composite material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords