Modular Scaffolding System Australian Standard Kwikstage Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Modular Scaffolding System Australian Standard Kwikstage Scaffolding

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Modular Scaffolding System Australian Standard Kwikstage Scaffolding

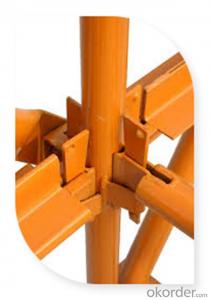

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Modular Scaffolding System Australian Standard Kwikstage Scaffolding

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:21M high full scaffold erection scheme

- dismantle4.1 the accurate preparation before dismantling the scaffold shall comply with the following requirements:1 should be a comprehensive inspection of the scaffold fastener connection, even wall pieces, support system is in line with the requirements of the structure;

- Q:How to calculate the vertical force of scaffolding

- The calculation of steel tubular scaffold with reference to "construction safety code for steel tubular scaffold with couplers" (JGJ130-2001). Need to calculate the following eight aspects:

- Q:What could you do with 100,000 jumbo cotton balls, 50 gallons of honey, and three story scaffolding?

- ummmm oh i got a good one i hope and that is to build the world's largest bee's hive. plus they make more honey and i would have tons of money, pretty sweet isn't it.

- Q:Okay so I want to get either done, I just want to know which one is more painful. Not felling that nervous because I have had my nose and tongue done. I want to know which one is more painful and how to clean each of them. And also with the lip, is it more like the tongue with what foods you can eat and how hard it is to eat?

- Everyone is different as far as what piercings they think hurt more or less, but based on my own experience, I'd say the scaffolding hurt more by far. Now, I've never had my lower lip pierced, but I had my upper lip area (I used to have angel bites), so I'd image it would have to be similar to the lower lip as far as pain, care, healing. As far as cleaning them, it's like most other piercings, where the best thing for you to use is warm sea salt water. But although everyone's different, the lip is going to be the faster healing of the two I'd say for basically anyone. The scaffolding takes up to a year to fully heal. The lip heals relatively fast;usually anything involving your mouth area heals quicker than other areas of the body-I'm sure you noticed how your tongue healed fast. Or even if you accidentally bite or cut anything involving your mouth, tongue, inside of your cheeks, etc., it heals faster than other areas. As far as the foods other aftercare with it, it is somewhat similar to your tongue in caring for it-just follow your piercer's instructions you'll be fine. Good luck!

- Q:What is a bowl buckle scaffold?

- The utility model has the advantages of reasonable structure, simple manufacturing process, easy operation and wide application range, and can fully meet the construction requirements of buildings, bridges and culverts, tunnels, chimneys, water towers and other buildings

- Q:Also what 2 cell populations in the body that don't routinely undergo cell division

- The first one is vague. The answer could be the mitotic spindle. It might be kinetochore microtubules. It might be talking about the kinetchores on the chromosomes instead of the microtubules that attach to the kinetochores. It could possibly even be talking about the centromeres, though to me that seems less likely. Neurons in the adult brain (and mature muscle cells?) do not routinely undergo cell division.

- Q:i am getting my industrial (scaffold) pierced on one ear and i want my cartilage on the other ear, how long do i have to wait between them? What are pros and cons for industrial (scaffold)? what are risks and stuff and how much is it? i want to get it so any information or anything i should know would be great thanks especially for industrial:)

- You can have both done in the same day if you can handle the pain and shock. Get the industrial done first, and if you still feel OK afterwords, you can get your other ear done by the same piercer. Talk to him/her and let them know what you want to do before you start. If you feel like you need to wait after the industrial, wait at least a day before getting the second piercing. It's all about what you can handle.

- Q:Exterior wall scaffold construction plan?

- Vertical pole:Double row scaffolding pole, pole top high eaves 1.5m structure. Single tube base for vertical rod bottom. The vertical rod joint is connected with a butt fastener, and the vertical rod and the large cross bar are connected by a right angle fastener. When the joint is staggered, the two adjacent column joints are avoided to be in the same span, and the distance between them is not less than 50cm; the distance between each joint center and the main node is not greater than 60cm.

- Q:What are the functions and requirements of the masonry wall

- 6, vertical closure: from the second step to the fifth step, each step required in the outer row of pole side door set like baluster 1.00m high and block feet or to set up protective net, rod (net) and the vertical rod fastened; more than fifth steps in a protective railing, should all the safety fence or security legislation net; in the street or densely populated areas, should be from the second step, the safety fence or outside of all network security legislation.7, scaffolding erection should be higher than the top of the building or the operating surface of 1.5m or more, and add enclosure.

- Q:improper design of formwork and scaffolding, not adequate braces and supports, improper handling, corrosion of material is several factor of formwork and scaffolding failure. it is estimated that more than 3000 accidents involving falls from scaffolds and 30 fatalities

- Improper assembly seems to be a big one. Workers often neglect to install the internal diagonal from upper corner to opposite lower corner when it comes to scaffolding. Formwork usually fails by inadequate bracing at the bottom as hydrostatic pressure builds. This can be mitigated to some extent by allowing the concrete to set up a bit before pouring the next layer. For earth formwork, you have to be real careful about expansive clay becoming saturated and overwhelming the bracing as it expands.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Modular Scaffolding System Australian Standard Kwikstage Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords