Modified Rubber Asphalt SBS Bituminous Waterproofing Membrane For Bridge In Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

CE approved waterproof membrane price , self adhesive textured roll sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application method:

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

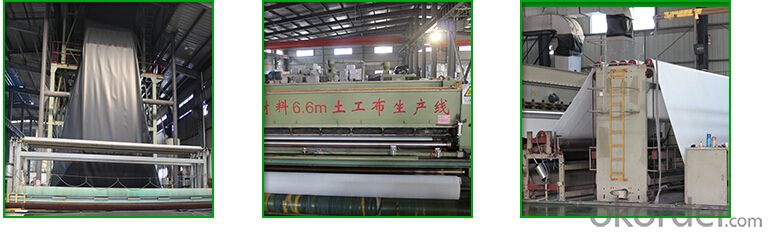

Product line&test

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Why choose us ?

We have 20 years manufacturer experience

10000-30000 square meter factory size,more than 10 production lines

We will be your best partner,provide high quality products with CE,ISO,SGS

approved in competitive prive,sincerely hope to make a win-win cooperation with you.

FAQ

- Q:What is the best waterproofing membrane for my project?

- The best waterproofing membrane for your project depends on various factors such as the type of project, the specific requirements, and the budget. There are several options available in the market, each offering different features and benefits. One popular choice is a bituminous waterproofing membrane. It is a cost-effective option suitable for a wide range of projects, including roofs, basements, and foundations. Bituminous membranes are durable, flexible, and capable of withstanding extreme weather conditions. They can be applied using torch-on, self-adhesive, or hot-melt methods. Another option to consider is a polyurethane liquid membrane. This type of membrane provides excellent elasticity, making it ideal for areas that require flexibility, such as balconies, terraces, and swimming pools. Polyurethane membranes are resistant to UV rays and can be easily applied by brush or roller. For projects that require a high level of durability and resistance, a cementitious waterproofing membrane might be the best choice. It is a mixture of cement, sand, and special additives that create a thick, protective layer. Cementitious membranes are commonly used for underground structures, tunnels, and water tanks. If your project involves below-grade applications or areas with high water pressure, a bentonite waterproofing membrane could be the best option. Bentonite membranes are made of clay minerals that swell when exposed to water, forming a watertight barrier. They are commonly used in basements, foundations, and retaining walls. Ultimately, the best waterproofing membrane for your project will depend on the specific requirements, budget, and preferences. It is recommended to consult with a professional waterproofing contractor who can assess your project's needs and recommend the most suitable membrane system.

- Q:Can a waterproofing membrane be applied on top of roofing materials?

- Yes, a waterproofing membrane can be applied on top of roofing materials. In fact, this is a common practice in the construction industry. The primary purpose of a waterproofing membrane is to provide an additional layer of protection against water infiltration, which is especially important in areas prone to heavy rainfall or where the roof is exposed to extreme weather conditions. By applying a waterproofing membrane on top of roofing materials, it creates a barrier that prevents water from seeping through the roof and causing damage to the underlying structure. Additionally, depending on the type of waterproofing membrane used, it can also provide added insulation and improve the overall energy efficiency of the building. It is important to note that proper installation and adherence to manufacturer's guidelines are crucial to ensure the effectiveness and longevity of the waterproofing system. Therefore, it is recommended to consult with a professional roofing contractor or waterproofing specialist to determine the most suitable membrane and installation method for your specific roofing materials and conditions.

- Q:Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to consider a few factors when applying these membranes in low temperatures. Cold weather can affect the curing process of the membrane, potentially slowing it down. It is crucial to ensure that the surface being waterproofed is dry and free from ice or frost before applying the membrane. Additionally, some waterproofing products may have specific temperature requirements for optimal performance, so it is essential to consult the manufacturer's guidelines. In colder temperatures, it may also be necessary to use specialized adhesives or primers designed for cold weather applications. Overall, with proper precautions and the use of appropriate materials, waterproofing membranes can be successfully applied in cold weather.

- Q:Can waterproofing membranes be used on terraces?

- Terraces can definitely benefit from the use of waterproofing membranes. In fact, it is highly recommended to apply these membranes to protect the terrace's structural integrity and prevent any water damage. Waterproofing membranes act as a barrier, effectively stopping water from seeping into the terrace and causing undesirable leaks or cracks. They are commonly utilized on flat terraces, rooftop terraces, and even balconies to guarantee that water does not infiltrate the surface and cause harm to the underlying structure. Waterproofing membranes come in a variety of types, including liquid-applied, sheet, and self-adhesive membranes, offering diverse options that cater to the specific needs of the terrace. By applying a waterproofing membrane, the terrace can be safeguarded against moisture, UV rays, and other environmental factors, ultimately prolonging its lifespan and ensuring a resilient and long-lasting surface.

- Q:Can a waterproofing membrane be used for a podium deck?

- Indeed, a podium deck can utilize a waterproofing membrane. A podium deck refers to an elevated platform or structure commonly found in commercial buildings or multi-story residential complexes. Given its raised position, a podium deck is exposed to various weather elements, including rain and moisture. Consequently, it becomes imperative to implement a dependable waterproofing system to shield the underlying structure from water-related harm. A waterproofing membrane emerges as a popular option for podium decks due to its ability to serve as an effective barrier against water infiltration. Generally, this membrane is applied beneath the deck's surface, acting as a protective layer that thwarts water from permeating the underlying structure. Its design prioritizes durability, flexibility, and resistance to weathering, guaranteeing long-term protection for the deck. Additionally, a waterproofing membrane can yield supplementary advantages for a podium deck. It can function as a vapor barrier, preventing the accumulation of moisture within the structure, which could lead to mold growth and material deterioration. Moreover, certain waterproofing membranes offer heightened UV resistance, contributing to the deck's longevity and aesthetic appeal preservation. When selecting a waterproofing membrane for a podium deck, it is crucial to consider factors such as the deck's design, projected foot traffic levels, and local climate conditions. Different membrane types, including sheet membranes, liquid membranes, or spray-applied membranes, may be suitable depending on the specific project requirements. In conclusion, employing a waterproofing membrane indeed proves suitable for a podium deck. It furnishes a reliable and effective solution for safeguarding the deck and underlying structure from water damage, thereby ensuring the durability and functionality of the podium deck.

- Q:Can a waterproofing membrane be used on precast iron surfaces?

- Yes, a waterproofing membrane can be used on precast iron surfaces. A waterproofing membrane is a thin layer of material that is applied to a surface to prevent the penetration of water or moisture. It can be applied to a variety of surfaces, including precast iron surfaces. The waterproofing membrane acts as a barrier, preventing water from seeping into the precast iron and causing damage such as rust or corrosion. This can be particularly important in areas where the precast iron surface is exposed to water or moisture, such as in outdoor installations or areas with high humidity levels. The use of a waterproofing membrane on precast iron surfaces can help to extend the lifespan of the structure and maintain its structural integrity.

- Q:Can a waterproofing membrane be used on copper surfaces?

- Indeed, copper surfaces can be prone to corrosion and moisture-related damage. In order to safeguard them, it is possible to utilize a waterproofing membrane. By implementing this measure, an extra level of protection is afforded. The membrane serves as a barrier, effectively preventing water and moisture from infiltrating the copper surface. Consequently, corrosion is impeded and the lifespan of the copper material is extended. It is crucial to exercise caution when selecting a compatible waterproofing membrane to ensure optimal adhesion and efficacy. Furthermore, it is imperative to diligently adhere to appropriate surface preparation and application techniques to guarantee a triumphant waterproofing solution for copper surfaces.

- Q:How does a waterproofing membrane handle construction joints?

- A waterproofing membrane is designed to provide a protective barrier against water penetration in construction applications. When it comes to construction joints, which are commonly found in concrete structures, the membrane is specifically engineered to handle these areas. During the construction process, joints are created to allow for movement between different sections of the structure. These joints can be vulnerable points where water can potentially infiltrate. To address this concern, waterproofing membranes are installed to ensure that these joints remain watertight. There are different methods used to handle construction joints with waterproofing membranes. One common approach is to apply the membrane directly over the joint, extending it beyond the joint edges. This creates a continuous waterproof layer that covers both the joint and the adjoining areas. Another technique involves the use of specially designed joint tapes or strips that are embedded within the membrane. These tapes or strips are typically made of materials like rubber or PVC and are placed directly over the joint before the membrane is applied. They serve as an additional layer of protection, enhancing the waterproofing performance of the membrane at the joint. In addition to these methods, there are also specialized waterproofing systems available that include pre-formed joint sealants. These sealants are designed to fit snugly into the joint, providing a tight seal against water intrusion. The membrane is then installed over the joint, ensuring comprehensive waterproofing coverage. Overall, a waterproofing membrane is specifically designed to handle construction joints by providing a durable and effective barrier against water penetration. Whether through extending the membrane over the joint, using joint tapes or strips, or incorporating pre-formed joint sealants, these membranes ensure that construction joints remain watertight, protecting the structure from potential water damage.

- Q:Can a waterproofing membrane be used for tunnels and subway stations?

- Yes, a waterproofing membrane can be used for tunnels and subway stations. The membrane acts as a barrier against water infiltration and helps protect the structure from water damage. It is commonly used in underground construction projects to ensure the longevity and safety of tunnels and subway stations.

- Q:Can a waterproofing membrane be used in temporary or temporary structures?

- Indeed, temporary or transient structures can benefit from the utilization of a waterproofing membrane. These specialized membranes are crafted to establish a safeguard against the infiltration of water, a critical measure in thwarting any potential moisture-related harm in various architectural formations. Be it a fixed or impermanent construction, such as a provisional refuge, tent, or temporary worksite, the application of a waterproofing membrane guarantees the attainment of water resistance and protection. Consequently, it becomes imperative to meticulously select a waterproofing membrane that aligns with the distinct requisites of the temporary structure, while adhering to the appropriate installation protocols to ensure its utmost efficacy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Modified Rubber Asphalt SBS Bituminous Waterproofing Membrane For Bridge In Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords