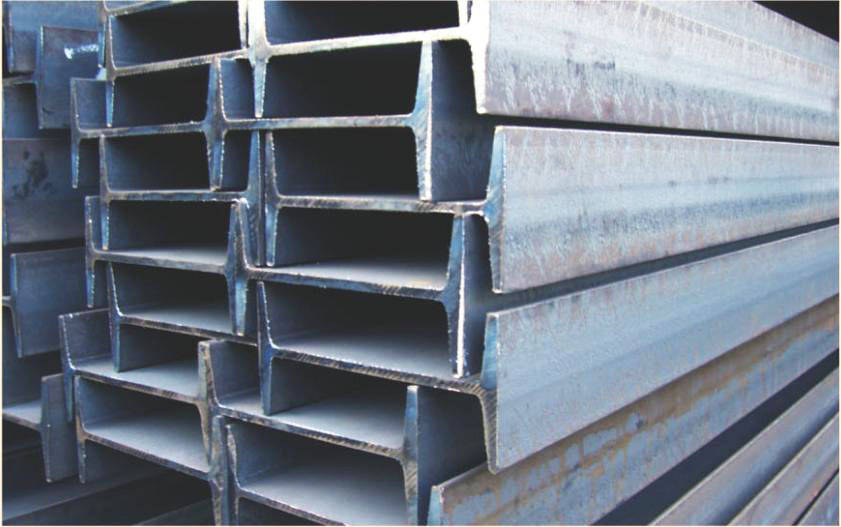

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Mild Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Brand: Jinding

Grade: SS400 – SS490

Standard: JIS, ASTM, GB

Packaging: Export packing, nude packing, bundled

Place of Origin: Hebei, China

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How do Steel I-Beams perform in terms of insulation?

- Steel I-beams do not perform well in terms of insulation. As a structural material, steel has excellent strength and durability, but it is a poor insulator. Steel is a good conductor of heat, meaning it allows heat to transfer easily through its structure. This makes steel I-beams highly conductive and susceptible to thermal bridging, which can lead to heat loss or gain depending on the climate. To address this insulation challenge, additional insulation materials are often used alongside steel I-beams. These insulation materials, such as foam panels or fiberglass batts, are placed between or around the I-beams to minimize the heat transfer. This extra layer of insulation helps to create a more thermally efficient building envelope. It is important to note that the insulation performance of a building is not solely dependent on the steel I-beams. Other factors, such as the type and thickness of insulation materials, the overall building design, and the quality of installation, also play significant roles in achieving proper insulation.

- Q:Can steel I-beams be used in underground or tunnel construction?

- Yes, steel I-beams can be used in underground or tunnel construction. Steel I-beams are commonly used in construction due to their strength and durability. In underground or tunnel construction, where the structural integrity is crucial, steel I-beams are often used to support the weight of the structure and provide stability. They can be used as support beams to reinforce the roof, walls, or floor of a tunnel, ensuring that it can withstand the pressure and forces exerted on it. Additionally, steel I-beams can be easily fabricated and customized to fit the specific requirements of the underground or tunnel construction project, making them a versatile and reliable choice.

- Q:Can steel I-beams be used for historical building restoration?

- Yes, steel I-beams can be used for historical building restoration. In fact, steel I-beams are often the preferred choice for reinforcing and stabilizing historical structures. These beams provide significant structural support while minimizing the impact on the original architecture and aesthetic of the building. Historical buildings often suffer from structural issues due to aging, deterioration, or inadequate initial construction. Steel I-beams can be used to strengthen and stabilize compromised sections of the building, ensuring its longevity and safety. This is particularly important in areas with high seismic activity or heavy loads. The advantage of steel I-beams lies in their strength and versatility. They can be custom-made to fit the specific requirements of each restoration project, allowing for precise support in critical areas. Steel I-beams are also lightweight and can be easily transported and installed, minimizing disruption to the historical building during the restoration process. Moreover, steel I-beams can be concealed within the original structure, preserving the historical integrity of the building. This is crucial for maintaining the architectural authenticity and ensuring compliance with historical preservation guidelines. However, it is important to note that the decision to use steel I-beams for historical building restoration should be made in consultation with structural engineers, architects, and preservation specialists. These professionals will carefully assess the structural needs of the building and develop a restoration plan that respects the historical significance while incorporating the necessary reinforcements. In conclusion, steel I-beams are a viable option for historical building restoration. They provide the necessary strength and support while minimizing the impact on the building's historical fabric. With proper planning and expertise, steel I-beams can be successfully integrated into the restoration process, ensuring the preservation of historical buildings for future generations.

- Q:What are the environmental impacts of steel I-beam production?

- The environmental impacts of steel I-beam production include carbon dioxide emissions from the energy-intensive manufacturing process, deforestation and habitat destruction due to iron ore extraction, water pollution from mining activities, and the generation of waste materials such as slag and scale. Additionally, the transportation of raw materials and finished products contributes to air pollution and greenhouse gas emissions. However, advancements in technology and sustainable practices are being implemented to reduce these impacts.

- Q:What are the different types of steel finishes for I-beams?

- Different types of steel finishes can be applied to I-beams, each with their own unique characteristics and advantages. Some commonly used finishes include: 1. Mill Finish: This is the most basic and widely used steel finish for I-beams. It refers to the natural surface of the steel after it has been formed and processed. Mill finish gives a smooth, slightly reflective appearance but does not provide much protection against corrosion. 2. Hot-dip Galvanized: In this finish, the I-beams are immersed in molten zinc, resulting in a zinc coating on the surface. Galvanizing offers excellent corrosion protection, making it suitable for outdoor applications or environments with high moisture levels. The coating's appearance can vary from shiny silver to dull gray, depending on the thickness of the zinc layer. 3. Painted: I-beams can be painted with different types of coatings, including epoxy, enamel, or polyurethane paints. Painting not only enhances the steel's appearance but also acts as a protective barrier against corrosion. Various colors and finishes can be chosen to meet specific aesthetic or functional requirements. 4. Powder-coated: This finish involves applying a dry powder to the surface of the I-beam, which is then cured with heat to create a durable and decorative finish. It offers a wide range of colors and finishes, such as smooth, textured, or metallic appearances. Powder coating provides excellent resistance to corrosion, impact, and fading, making it suitable for both indoor and outdoor use. 5. Stainless Steel: I-beams can be made from stainless steel, which naturally has good corrosion resistance. Stainless steel finishes can range from bright, reflective surfaces (like a mirror finish) to brushed or satin finishes, depending on the desired appearance and application requirements. 6. Blackened: Blackening is a chemical treatment that creates a dark oxide layer on the steel's surface. This finish is often chosen for aesthetic purposes, giving a unique and rustic appearance. However, it does not provide significant corrosion resistance and may require additional protective measures if used in outdoor or corrosive environments. When selecting a steel finish for I-beams, it is important to consider the intended application, environment, and desired appearance. Consulting with a steel supplier or structural engineer can help determine the most suitable finish for your specific needs.

- Q:What are the common design standards for steel I-beams?

- The common design standards for steel I-beams include the American Institute of Steel Construction (AISC) Manual of Steel Construction, which provides guidelines for the design, fabrication, and erection of structural steel. Additionally, other widely recognized design standards include the European Norm (EN) series, British Standards (BS), and the Canadian Standards Association (CSA) standards. These standards typically cover aspects such as the dimensions, material specifications, load-bearing capacities, and allowable deflections of steel I-beams.

- Q:What is the material of hot rolled ordinary I-beam?

- I-beam is also called steel girder (English name Universal Beam). It is a strip of steel with an I-shaped section. I-beam is made of ordinary I-beam and light i-beam. It is a section steel with an I-shaped section.

- Q:Can steel I-beams be used in railway bridges?

- Indeed, railway bridges can incorporate steel I-beams. The utilization of steel I-beams in bridge construction is widespread owing to their remarkable strength-to-weight ratio, durability, and adaptability. These beams possess the capacity to bear substantial loads and can be tailored to cover expansive spans, rendering them well-suited for railway bridges. By employing steel I-beams in railway bridges, one can ensure the integrity and safety of the structure, all while enabling efficient and economical construction. Furthermore, the fabrication and installation of steel I-beams are straightforward, rendering them a favored option for railway bridge endeavors.

- Q:How are steel I-beams inspected for quality control?

- Steel I-beams are inspected for quality control through a series of visual inspections, dimensional measurements, and non-destructive testing techniques. This may include checking for any visible defects, such as cracks, surface roughness, or uneven welds. Additionally, measurements are taken to ensure the beam's dimensions and tolerances are within the specified range. Non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection, are also employed to detect any internal defects or discontinuities that may affect its structural integrity. Overall, a thorough inspection process is carried out to ensure that steel I-beams meet the required quality standards.

- Q:What is the modulus of elasticity of No. 16 I-beam?

- The modulus of elasticity of No. 16 I-beam is 206000 N/mm2.Generally speaking, the elastic body exerts an external function, and the elasticity experiences the change of the shape (called strain). The general definition of the elastic modulus is that the stress is divided by the strain.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords