Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

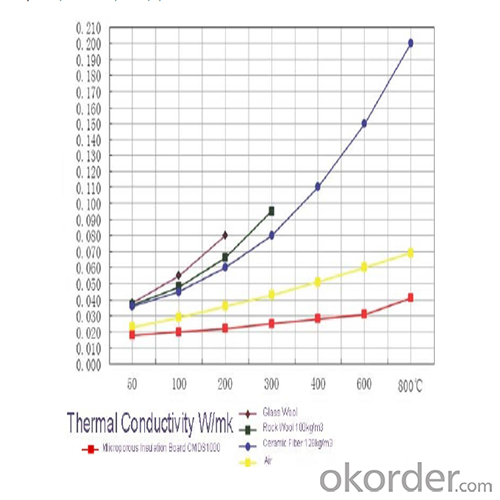

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

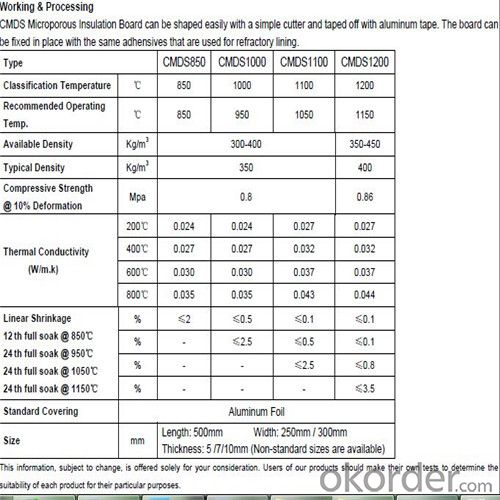

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:How do glass fiber textiles contribute to weather resistance?

- Glass fiber textiles contribute to weather resistance by providing a durable and protective layer against various weather elements. The inherent properties of glass fibers, such as high tensile strength and resistance to moisture, UV rays, and temperature fluctuations, make them ideal for withstanding harsh weather conditions. Additionally, glass fiber textiles can be designed to have excellent dimensional stability and low thermal expansion, further enhancing their ability to resist weather-related wear and tear.

- Q:How does glass fiber textile perform in high-temperature environments?

- Glass fiber textile is renowned for its outstanding heat resistance properties, rendering it highly appropriate for utilization in environments with high temperatures. The material exhibits poor heat conductivity and possesses a high melting point, enabling it to sustain its structural integrity even under elevated temperatures. This renders glass fiber textile an ideal choice for situations necessitating thermal insulation, such as the production of protective apparel for firefighters or workers in foundries and steel mills. Within high-temperature surroundings, glass fiber textile showcases minimal shrinkage or deformation, ensuring its stability and durability. It does not ignite or emit toxic fumes when exposed to flames, making it a secure selection for fire-resistant applications. Moreover, glass fiber textile possesses low thermal conductivity, meaning that it does not readily transfer heat. This characteristic aids in reducing heat transfer to the surroundings, thereby offering efficient insulation and safeguarding individuals against heat-related hazards. Furthermore, glass fiber textile displays resistance towards chemical corrosion, rendering it suitable for usage in industries where exposure to harsh chemicals or acidic environments is commonplace. It is also highly resilient, demonstrating excellent resistance against abrasion and wear, thereby enabling it to withstand the rigorous conditions of high-temperature environments. In summary, glass fiber textile performs exceptionally well in high-temperature environments due to its heat resistance, non-flammability, thermal insulation properties, and resistance to chemical corrosion. Its capacity to maintain structural integrity and provide effective insulation makes it a dependable option for various industrial applications where exposure to extreme heat is a concern.

- Q:Can glass fiber textiles be knitted?

- Glass fiber textiles cannot be knitted, as they comprise delicate glass strands that are usually woven together to produce a fabric. Knitting, however, entails intertwining loops of yarn or thread to form a fabric. Due to their fragility, glass fibers are prone to breakage when subjected to the knitting process. Furthermore, glass fibers lack the flexibility and elasticity found in yarn or thread, rendering them unsuitable for knitting. Consequently, glass fiber textiles are predominantly woven instead of being knitted.

- Q:Can glass fiber textiles be used for reinforcement in plastics?

- Yes, glass fiber textiles can be used for reinforcement in plastics. Glass fibers are strong and provide excellent mechanical properties when used as reinforcement in plastics. They enhance the strength, stiffness, and impact resistance of the final plastic composite. Glass fiber textiles are widely used in industries such as automotive, aerospace, construction, and consumer goods to reinforce plastic parts and components. The combination of glass fibers and plastics creates a composite material that is lightweight, durable, and has high tensile strength.

- Q:Can glass fiber textiles be used for making insulation blankets or wraps?

- Glass fiber textiles offer a range of applications in insulation. They possess exceptional thermal insulation properties and are widely utilized across multiple industries for insulation purposes. These textiles effectively resist heat due to their composition of fine glass fibers that trap air and minimize heat transfer. Their versatility allows for the insulation of pipes, ducts, tanks, and other equipment to prevent heat loss or gain. Furthermore, they exhibit resistance to moisture and provide acoustic insulation. Their lightweight, flexible, and durable nature further enhances their suitability for insulation in various settings. However, it is crucial to exercise caution when handling glass fiber textiles, as they may cause skin, eye, and respiratory irritation if not adequately protected.

- Q:Can glass fiber textiles be used in solar panels?

- Yes, glass fiber textiles can be used in solar panels. They are often used as reinforcement materials in the manufacturing of solar panels, providing mechanical strength and durability to the panel structure. Additionally, glass fiber textiles can help improve the overall performance and reliability of solar panels by reducing the risk of mechanical failure and extending their lifespan.

- Q:Can glass fiber textiles be used for automotive interiors?

- Yes, glass fiber textiles can be used for automotive interiors. Glass fiber textiles offer various benefits such as durability, heat resistance, and sound insulation, making them suitable for automotive applications. They can be used for seat covers, headliners, door panels, and other components to enhance the aesthetics and functionality of automotive interiors.

- Q:Can glass fiber textiles be used in reinforcement of coir fibers?

- Yes, glass fiber textiles can be used as a reinforcement material for coir fibers. The combination of glass fiber textiles and coir fibers can enhance the overall strength and durability of the composite material.

- Q:How do glass fiber textiles compare to aramid textiles?

- Glass fiber textiles and aramid textiles have different properties and applications. Glass fiber textiles are known for their excellent strength, high temperature resistance, and electrical insulating properties. They are commonly used in industries such as automotive, aerospace, and construction. Aramid textiles, on the other hand, are known for their exceptional heat resistance, high tensile strength, and flame retardancy. They find applications in industries like military, firefighting, and protective clothing. While both textiles have their unique advantages, the choice between glass fiber and aramid textiles ultimately depends on the specific requirements of the application.

- Q:What are the environmental impacts of glass fiber textile production?

- There are several environmental consequences associated with the production of glass fiber textiles. First and foremost, a significant amount of energy is required to produce these materials, often obtained from non-renewable fossil fuels. This energy consumption contributes to greenhouse gas emissions and climate change. Moreover, the manufacturing process of glass fiber textiles involves the utilization of various chemicals, such as resins, binders, and solvents. If not properly managed, these chemicals can pose a threat to both human health and the environment. They have the potential to contaminate air, water, and soil, leading to pollution and potential ecological damage. Additionally, the production of glass fiber textiles necessitates the extraction and processing of raw materials like silica sand, limestone, and soda ash. This extraction process can result in habitat destruction, soil erosion, and water pollution. Furthermore, it can deplete natural resources, particularly as the demand for glass fiber textiles continues to rise. Lastly, the disposal of glass fiber textiles at the end of their lifecycle presents another environmental challenge. Unlike natural fibers, glass fibers do not easily degrade and can persist in the environment for an extended period. Improper disposal can lead to accumulation in landfills, exacerbating waste management issues. To address these environmental impacts, manufacturers must adopt cleaner production techniques, such as utilizing renewable energy sources and reducing the use of hazardous chemicals. Recycling and reusing glass fiber textiles can also help minimize waste and conserve resources. Additionally, it is crucial to promote sustainable consumption patterns and raise awareness among consumers about the environmental consequences of glass fiber textiles, thereby encouraging responsible production and consumption practices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords