Mesh Shape Castable For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Shape Castable For Fireplace and Industrial Furnace

Product Description:

Mesh shape castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The Mesh shape castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.They are widely used in various kinds of kiln lining.Such as boiler, blast furnace hot blast stove, heating furnace, ceramic kiln, etc.Furnaces of metallurgy industry, heat treatment furnace. Furnace of incineration of garbage, recirculating fluidized bed furnace. Furnaces of chemical industry and construction industry.

Product Applications:

For feature of Mesh shape castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

They can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Main Product Features:

1. High refractoriness, High refractoriness under load.

2. High density, low porosity.

3. Good slag resistance and corrosion resistance.

4. High strength and wear resistance.

5. Good resistance to flake performance.

6. Good thermal shock stability.

7. Scouring resistance

8. Good hot strength.

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

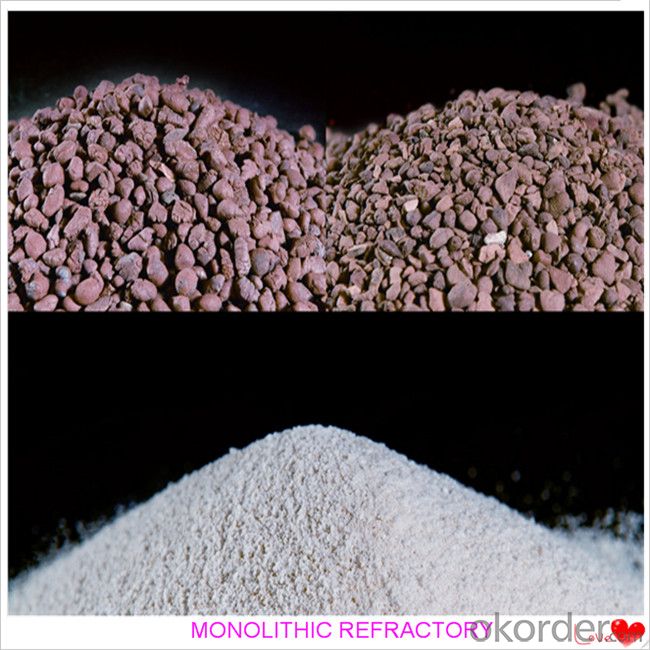

Product Picture:

- Q:How do monolithic refractories perform in reheating furnace roof applications?

- Monolithic refractories are highly effective in reheating furnace roof applications. These refractories are known for their excellent thermal shock resistance, which is crucial in the extreme temperature conditions inside a reheating furnace. They can withstand rapid temperature changes without cracking or spalling, ensuring the longevity and durability of the furnace roof. Additionally, monolithic refractories offer superior insulation properties, which help in maintaining the desired temperature inside the furnace. These refractories have low thermal conductivity, preventing heat loss and reducing energy consumption. This not only improves the energy efficiency of the furnace but also contributes to cost savings for the operators. Furthermore, monolithic refractories provide excellent resistance to chemical attacks from gases and molten metals present in the furnace environment. They are designed to withstand corrosive atmospheres and prevent the penetration of harmful substances, thus prolonging the life of the roof refractory. Moreover, monolithic refractories offer easy installation and repair options. Their ability to be cast or gunned in place allows for a seamless and precise application to the roof structure. This feature also enables quick and efficient repairs or maintenance, minimizing downtime and production losses. In conclusion, monolithic refractories are a reliable and efficient choice for reheating furnace roof applications. Their exceptional thermal shock resistance, insulation properties, chemical resistance, and ease of installation make them an ideal solution for maintaining the structural integrity and performance of the furnace roof.

- Q:What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that are composed of a single, homogeneous structure, as opposed to being made up of multiple separate pieces. They are different from other refractory materials, such as bricks or tiles, which are assembled together to form a lining. Monolithic refractories are typically made from a combination of aggregates, binders, and additives, which are mixed together and applied in a plastic or semi-plastic state. This allows for easier installation, as they can be shaped and formed to fit the specific dimensions of the furnace or kiln. Additionally, monolithic refractories offer benefits such as better thermal shock resistance, reduced joints and seams, and improved overall performance due to their seamless nature.

- Q:What are the specific requirements of monolithic refractories for soaking pit applications?

- Monolithic refractories for soaking pit applications must meet several specific requirements. Firstly, they need to withstand high temperatures and thermal cycling. This means they must be able to endure temperatures exceeding 1500 degrees Celsius without significant degradation. The longevity and durability of the refractories depend on this capability. Secondly, the refractories must have good thermal shock resistance. Since soaking pits often experience rapid changes in temperature, the refractories must be able to handle these fluctuations without cracking or spalling. This is vital to maintain the refractories' integrity. Chemical attacks are another concern in soaking pit applications. Molten metal, slag, and other corrosive substances are present, so the refractories must have excellent chemical resistance. This prevents erosion and chemical reactions. Withstanding the corrosive effects of molten metal and slag, as well as potential chemical reactions, is crucial. Furthermore, mechanical stresses, such as abrasion and impact, occur in soaking pits due to the movement and handling of metal ingots. The monolithic refractories should possess good mechanical strength and abrasion resistance to withstand these stresses. They should be able to resist wear and tear caused by heavy loads and avoid any mechanical failure. Lastly, the refractories used in soaking pits should be easy to work with and install. This ensures efficient and effective lining of the pit, minimizing any gaps or cracks that could lead to heat loss or chemical penetration. In summary, monolithic refractories for soaking pit applications must meet specific requirements regarding high temperature resistance, thermal shock resistance, chemical resistance, mechanical strength, and ease of installation. Fulfilling these requirements guarantees that the refractories can withstand the harsh conditions of soaking pits and maintain their performance and integrity over an extended period.

- Q:What are the common manufacturing processes used for monolithic refractories?

- The common manufacturing processes used for monolithic refractories include: 1. Mixing: The first step in the manufacturing process is the proper mixing of the raw materials. This involves carefully measuring and combining the different ingredients to ensure a homogeneous mixture. 2. Wetting: Once the ingredients are mixed, water or a liquid binder is added to wet the mixture. This helps in improving the workability and plasticity of the material, making it easier to shape and mold. 3. Forming: The wet mixture is then shaped into the desired form using various techniques such as casting, gunning, ramming, or extrusion. Casting involves pouring the wet mixture into a mold and allowing it to solidify, while gunning uses a spray gun to apply the material onto a surface. Ramming involves compacting the wet mixture into a mold using a ramming tool, and extrusion involves forcing the wet mixture through a die to create specific shapes. 4. Drying: After forming, the shaped monolithic refractory is dried to remove any excess moisture. This is typically done in a controlled environment with specific temperature and humidity conditions to prevent cracking or warping. 5. Firing: Once dried, the monolithic refractory is fired at high temperatures to achieve its desired properties. This process, known as sintering, helps in bonding the particles together and increasing the strength and stability of the material. 6. Finishing: After firing, the monolithic refractory may undergo additional finishing processes such as grinding, polishing, or coating to improve its surface quality and enhance its performance. These common manufacturing processes ensure the production of high-quality monolithic refractories with consistent properties and performance characteristics.

- Q:What are the key factors to consider when designing the lining system with monolithic refractories?

- When designing a lining system with monolithic refractories, there are several key factors that need to be considered in order to ensure optimal performance and longevity of the lining. These factors include: 1. Material selection: Choosing the right monolithic refractory material is crucial. Factors such as the operating temperature, chemical environment, and mechanical stress need to be taken into account. Different monolithic refractories have varying properties and performance characteristics, so selecting the most suitable material for the specific application is essential. 2. Thermal expansion: Monolithic refractories, like any other material, expand and contract with changes in temperature. It is important to consider the thermal expansion properties of the refractory material and how it will interact with the surrounding structure. Proper expansion joints or design features should be incorporated to accommodate thermal expansion and prevent cracking or spalling. 3. Installation technique: The method of installation plays a critical role in the performance of the lining system. It is important to follow the manufacturer's guidelines for mixing, placing, and curing the monolithic refractory material. Improper installation can lead to reduced lining integrity, decreased thermal conductivity, and compromised structural stability. 4. Bonding and anchoring: Ensuring a strong bond between the monolithic refractory and the substrate is essential for effective lining performance. Proper surface preparation, selection of suitable bonding agents, and appropriate anchoring techniques should be considered to enhance the adhesion and stability of the lining system. 5. Structural design: The structural design of the lining system should be carefully planned to withstand the mechanical stresses and operational conditions. Factors such as load-bearing capacity, thermal shock resistance, and thermal cycling should be taken into consideration during the design phase. Reinforcement materials, such as steel fibers or mesh, may be required to enhance the structural integrity and prevent cracking or spalling. 6. Maintenance and repair: Anticipating the need for maintenance and repair is crucial for the longevity of the lining system. Consideration should be given to access points, inspection ports, and repair techniques. Regular inspections and proactive maintenance can help identify and address any issues before they escalate and lead to major failures. By considering these key factors when designing the lining system with monolithic refractories, one can ensure a well-designed and effective lining that can withstand the harsh conditions and provide long-term performance.

- Q:How do monolithic refractories withstand the alkali attacks in cement kiln applications?

- Due to their unique composition and structure, monolithic refractories are capable of withstanding alkali attacks in cement kiln applications. Unlike traditional brick refractories, these refractories are made from a single material, resulting in a more uniform and dense structure. When exposed to alkali attacks in cement kilns, monolithic refractories create a barrier against the corrosive alkali substances by forming a protective layer on the surface. This protective layer is formed through reactions between the alkali substances and the refractory material, leading to the development of a stable compound that resists further attacks. Additionally, monolithic refractories possess high chemical resistance, allowing them to endure the aggressive conditions inside cement kilns. Their low porosity design minimizes the infiltration of alkali substances into the refractory material, reducing the risk of alkali attacks and extending the lifespan of the refractory lining. Furthermore, monolithic refractories are frequently manufactured using materials with elevated melting points, such as alumina, silica, and magnesia. These materials exhibit exceptional thermal stability, enabling the refractories to withstand the high temperatures in cement kilns without significant deterioration. This thermal stability is crucial in preventing the formation of cracks and spalling, which could permit alkali penetration and subsequent harm to the refractory lining. In conclusion, monolithic refractories are specifically engineered to resist alkali attacks in cement kiln applications by forming a protective layer, possessing high chemical resistance, and demonstrating excellent thermal stability. These characteristics make them an ideal choice for lining cement kilns, ensuring long-term performance and durability.

- Q:What are the key properties and characteristics of monolithic refractories?

- Monolithic refractories, renowned for their ability to be shaped or installed in a single piece without joints, are a type of refractory material. They find their utility in high-temperature applications where traditional brick or tile refractories may not suffice. One noteworthy attribute of monolithic refractories lies in their superior thermal stability. They can withstand extreme temperatures without significant expansion or contraction, making them an ideal choice for furnaces, kilns, and other heat-intensive environments. This quality ensures the maintenance of their structural integrity and grants long-lasting performance. Another significant characteristic of monolithic refractories is their high resistance to thermal shock. They can endure abrupt temperature changes without cracking or spalling, a crucial aspect when the refractory material is exposed to alternating hot and cold conditions. The resistance to thermal shock ensures the refractory lining's longevity, reducing the need for frequent repairs or replacements. Monolithic refractories also demonstrate commendable mechanical strength, enabling them to withstand the mechanical stresses and loads imposed on them during usage. They possess excellent load-bearing capacity, resisting abrasion, erosion, and impact, making them suitable for applications where the refractory material faces mechanical wear or impact. Moreover, monolithic refractories offer the advantage of easy installation and repair. Unlike traditional refractories that necessitate skilled labor and time-consuming bricklaying techniques, monolithic refractories can be cast, gunned, or sprayed into place. This effortless installation expedites turnaround times and minimizes downtime during repairs or maintenance. Lastly, monolithic refractories exhibit commendable chemical resistance to various corrosive agents, such as acids, alkalis, and molten metals. This property renders them suitable for use in industries where the refractory material encounters aggressive chemical environments, including the steel, petrochemical, and glass industries. In summary, monolithic refractories possess excellent thermal stability, high resistance to thermal shock, good mechanical strength, effortless installation and repair, and commendable chemical resistance. These properties establish them as the preferred choice in high-temperature applications where durability, reliability, and performance are of utmost importance.

- Q:How are monolithic refractories used in the repair and maintenance of ladle and tundish linings?

- Monolithic refractories are a type of refractory material that is commonly used in the repair and maintenance of ladle and tundish linings in the steel industry. These linings are crucial components of ladles and tundishes, which are used for the transportation and treatment of molten metal during the steelmaking process. When ladle and tundish linings are subjected to high temperatures and corrosive environments, they can deteriorate over time. This deterioration can lead to various issues such as heat loss, contamination of molten metal, and reduced refractory lining lifespan. To address these problems, monolithic refractories are used as repair and maintenance materials. Monolithic refractories are typically made from a combination of different refractory aggregates, binders, and additives. They are available in various forms, such as castables, gunning mixes, and ramming mixes. These materials are designed to be easily applied and shaped to conform to the specific geometry and dimensions of the ladle or tundish lining. During the repair process, the damaged areas of the lining are removed, and the monolithic refractories are then applied to these areas. Castables can be poured and vibrated into place, while gunning mixes can be sprayed using a high-pressure gunning machine. Ramming mixes, on the other hand, are manually compacted into the lining using a ramming tool. Monolithic refractories offer several advantages in the repair and maintenance of ladle and tundish linings. Firstly, their flexibility allows for easy installation and shaping, ensuring a snug fit to the lining. This helps to maximize the effectiveness of the refractory lining in preventing heat loss and maintaining the integrity of the ladle or tundish. Secondly, monolithic refractories have excellent thermal shock resistance and resistance to chemical attack. This makes them highly durable and capable of withstanding the harsh conditions encountered in ladles and tundishes. They can withstand repeated heating and cooling cycles without cracking or spalling, providing long-lasting protection to the lining. Lastly, monolithic refractories can be easily repaired and replaced when necessary. Their application and removal processes are relatively straightforward, allowing for efficient maintenance of ladle and tundish linings. This helps to minimize downtime and maintain the overall productivity of the steelmaking process. In conclusion, monolithic refractories play a crucial role in the repair and maintenance of ladle and tundish linings. Their ease of application, excellent thermal shock resistance, and resistance to chemical attack make them ideal materials for extending the lifespan and optimizing the performance of these linings in the steel industry.

- Q:How do monolithic refractories withstand thermal shock?

- Monolithic refractories withstand thermal shock due to their unique composition and structure. They are made from a single, continuous material with no joints or seams, which allows them to expand and contract uniformly under extreme temperature changes. Additionally, monolithic refractories possess excellent thermal conductivity, which enables them to quickly dissipate heat and minimize stress build-up. These properties make them highly resistant to thermal shock and capable of withstanding rapid temperature fluctuations without cracking or breaking.

- Q:How do monolithic refractories perform in aluminum holding furnace applications?

- Monolithic refractories have proven to be highly efficient and effective in aluminum holding furnace applications. These refractories are specifically designed to withstand the extreme temperatures and chemical environments encountered in these furnaces. One key advantage of monolithic refractories is their ability to form a continuous, seamless lining in the furnace. This eliminates the need for individual bricks or tiles, reducing the risk of thermal shock and cracking. The absence of joints also minimizes the chances of molten aluminum leaking through the lining, ensuring better containment and heat retention. Monolithic refractories also offer excellent thermal insulation properties, which are crucial in aluminum holding furnaces. They have low thermal conductivity, which helps to reduce heat loss and maintain a stable temperature within the furnace. This results in improved energy efficiency and reduced operating costs. Moreover, monolithic refractories have excellent resistance to corrosion and chemical attack from molten aluminum and its by-products, such as dross and fluxes. This resistance ensures a longer service life for the refractory lining, reducing maintenance and downtime. Additionally, monolithic refractories are known for their easy installation and repair. They can be installed quickly and easily, requiring minimal downtime for furnace maintenance. In case of any localized damage or wear, repairs can be made efficiently by patching or spraying the affected area. In summary, monolithic refractories are an ideal choice for aluminum holding furnace applications due to their seamless lining, thermal insulation properties, resistance to corrosion, and easy installation and repair. These refractories significantly contribute to the overall performance and efficiency of aluminum holding furnaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mesh Shape Castable For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords