Light Weight Fiberglass Polypropylene Geogrid Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

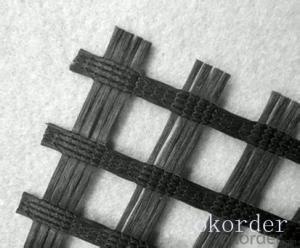

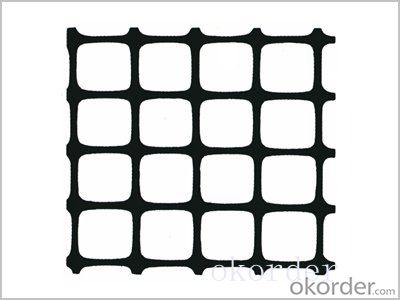

Biaxial

The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil..

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the specifications of the road geogrid

- Reference to the national standard, but the specifications are not necessarily the same as the national standard.

- Q:Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are commonly used in road construction for reinforcement of the soil, improving the stability and load-bearing capacity of the road. They are often used to reduce cracking and rutting, enhance pavement performance, and increase the overall lifespan of the road.

- Q:How do geogrids improve soil reinforcement?

- Geogrids improve soil reinforcement by providing tensile strength and stabilizing the soil, preventing excessive lateral movement and increasing load-bearing capacity.

- Q:What are the factors that affect the quality of glass fiber reinforced plastic grid

- Synthetic resin. Synthetic resin is used as the substrate of glass fiber reinforced plastics, which is used to paste the glass fiber into a whole. Because the resin is the base material, it has influence on the elastic modulus, heat resistance, electrical insulation, permeability, chemical corrosion resistance, weather resistance, aging resistance and so on.In addition, the interface is also an important factor affecting quality. The high performance of glass fiber reinforced plastic (FRP) grid cover is related to the quality and durability of the interface between fiber and resin. The interface has a great influence on the performance of glass fiber reinforced plastic grid. As everyone knows, the glass fiber is a cylindrical glass surface, such as glass, smooth, and the surface is often firmly adsorbed with a thin layer of water film, which certainly affect the bonding properties of glass fiber and resin. Especially in textile glass fiber drawing process, in order to achieve the collection, lubrication, eliminate the static, often coated with a layer of wetting agent, the wetting agent is the most paraffin substances remained on the surface of glass fiber on them, the isolation effect on synthetic resin and glass fiber, with both adhesive.

- Q:Characteristics of steel plastic geogrid

- 5, the use of high density polyethylene plastic composite grid can ensure that: at room temperature will not be affected by acid and alkali and salt solution, or oil erosion; will not be dissolved by water or microbial damage. At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage. But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields.

- Q:How do geogrids enhance the performance of reinforced embankments?

- Geogrids enhance the performance of reinforced embankments by providing additional tensile strength and stability to the soil layers. They help to distribute the load more evenly, reducing the potential for settlement and improving the overall stability of the embankment. Additionally, geogrids help to control lateral spreading of the soil, preventing slope failure and increasing the lifespan of the embankment.

- Q:What are the typical properties and characteristics of geogrids?

- Geogrids are typically made of high-strength polymers such as polyester or polypropylene, which give them excellent tensile strength and dimensional stability. They are characterized by their open-grid structure, allowing for soil interlocking and enhanced load distribution. Geogrids also possess high resistance to ultraviolet (UV) degradation and chemical corrosion, making them suitable for long-term applications in various environmental conditions. Additionally, these materials have low elongation under load, enabling them to provide long-term reinforcement and stabilization to soils and aggregates.

- Q:How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offers several advantages over other techniques. Unlike traditional methods like retaining walls or soil nails, geogrids are lightweight and easy to install, making them a cost-effective solution. Geogrids also provide excellent tensile strength and stability, increasing the load-bearing capacity of soil and preventing erosion. Additionally, geogrids are flexible and adaptable, allowing for better distribution of load and accommodating ground movements. Overall, geogrids are a superior choice for soil reinforcement due to their versatility, durability, and cost-efficiency.

- Q:What are the differences between geogrids and geocells?

- Geogrids and geocells are both materials used for soil reinforcement and stabilization, but they have distinct differences. Geogrids are typically made of high-strength synthetic materials such as polyester or polypropylene, and they are formed into a grid-like structure. They provide tensile strength to soil, preventing lateral movement and improving load distribution. On the other hand, geocells are three-dimensional cellular structures made from materials like high-density polyethylene. They create a honeycomb-like network that confines soil particles, preventing erosion and promoting load-bearing capacity. While geogrids are commonly used for soil stabilization in applications like road construction, geocells are often employed for erosion control and slope stabilization.

- Q:How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing reinforcement to soil, thereby reducing the need for excessive excavation and the use of concrete or other materials. This leads to a significant reduction in carbon emissions associated with production, transportation, and installation of such materials. Additionally, geogrids can enhance the stability and longevity of structures, reducing the need for maintenance and replacement, which further contributes to the reduction in carbon footprint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Weight Fiberglass Polypropylene Geogrid Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords