Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Steel Frame Formwork with Plastic Plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with Plastic plywood more and more popular in construction industry.

2. Main Features of Light Steel Frame Formwork with Plastic Plywood

-High quality of plastic plywood can stay solid with more than 7 hours in boiled water.

-Frame of plywood is made of plastic as well

-Repeated use of more than 20 times

-PP material used

-Plywood is used inside

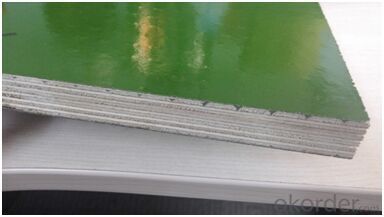

3. Light Steel Frame Formwork with Plastic plywood images

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with Plastic plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plastic Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Can steel frame formwork be used for circular or cylindrical structures?

- Circular or cylindrical structures can be constructed using steel frame formwork. This system is versatile and flexible, capable of easily adapting to various shapes and sizes, including circular or cylindrical structures. The adjustable steel frames can be curved or bent to match the desired shape of the structure. Furthermore, the formwork panels can be connected to the steel frames, resulting in a seamless and uninterrupted mold for pouring concrete. As a result, precise dimensions and smooth finishes can be achieved when constructing circular or cylindrical structures. In conclusion, steel frame formwork is a suitable option for creating circular or cylindrical structures due to its adaptability and capacity to produce intricate shapes.

- Q:How does steel frame formwork impact labor requirements?

- Steel frame formwork can have a significant impact on labor requirements in construction projects. One of the key advantages of steel frame formwork is its durability and reusability. Unlike traditional wooden formwork, steel frame formwork can be used multiple times, reducing the need for frequent replacement and thus reducing the labor required for formwork installation and removal. Additionally, steel frame formwork is lightweight and easy to handle, which makes it easier for laborers to assemble and disassemble. This not only saves time but also reduces the physical strain on workers, ultimately improving their productivity and reducing the risk of fatigue-related accidents. Moreover, steel frame formwork offers greater flexibility and precision in shaping concrete structures, allowing for more efficient and accurate construction. This accuracy reduces the need for manual adjustments, resulting in fewer errors and rework, thereby saving labor time and costs. Furthermore, steel frame formwork is known for its quick assembly and disassembly process. The standardized components can be easily interlocked, reducing the time and effort required for formwork installation and removal. This efficiency leads to faster construction progress and shorter project durations, ultimately reducing labor requirements. Overall, the use of steel frame formwork in construction projects positively impacts labor requirements by reducing the need for frequent replacements, enhancing worker productivity, minimizing errors, and facilitating quick assembly and disassembly.

- Q:Can steel frame formwork be used for both small and large-scale construction projects?

- Indeed, steel frame formwork is applicable to construction projects of varying scales, be it small or large. Its versatility and durability make it a highly adaptable and resilient system that can be effortlessly altered and reused, rendering it suitable for projects of diverse magnitudes. This system boasts exceptional strength and stability, enabling it to endure the immense pressures associated with larger projects, all while maintaining utmost accuracy and precision. Moreover, the ease with which steel frame formwork can be assembled and disassembled makes it highly efficient for deployment in a multitude of construction endeavors. In summary, steel frame formwork embodies a dependable and flexible solution that can be effectively employed in both small and large-scale construction projects.

- Q:How does steel frame formwork handle different types of formwork reinforcement?

- The construction technique known as steel frame formwork is highly versatile and robust. It is capable of effectively handling various types of formwork reinforcement. The steel frame itself provides a strong and stable structure, which supports both the formwork and the reinforcement materials. Steel frame formwork offers several advantages when it comes to different types of formwork reinforcement, such as steel bars and mesh. Firstly, the steel frame easily accommodates the placement and positioning of reinforcement materials. The formwork panels are specifically designed with slots and holes that allow for the insertion and secure positioning of steel bars and mesh. Moreover, steel frame formwork is capable of handling different sizes and configurations of reinforcement materials. The flexibility of the steel frame formwork allows for the customization of formwork panels, meeting the specific requirements of the reinforcement design. This adaptability ensures that the reinforcement materials are adequately supported and securely held in place during the concrete pouring process. Furthermore, steel frame formwork provides exceptional support and stability for the reinforcement materials. The steel frames are engineered to withstand the pressure and weight of the concrete, guaranteeing that the reinforcement remains in position without shifting or collapsing during the pouring and curing process. This stability is of utmost importance for the overall strength and integrity of the reinforced concrete structure. To summarize, steel frame formwork is an excellent choice for various types of formwork reinforcement. Its versatility, adaptability, and stability make it an ideal construction technique for projects requiring the utilization of reinforcement materials.

- Q:Can steel frame formwork be used for both single-storey and multi-storey structures?

- Steel frame formwork is applicable for both single-storey and multi-storey structures. This versatile and durable system can easily adapt to various heights and configurations. Its exceptional strength and stability make it ideal for high-rise buildings and structures with multiple floors. Furthermore, steel frame formwork enables efficient and fast construction, resulting in reduced project timelines and costs. Consequently, it is widely utilized in both single-storey and multi-storey construction projects.

- Q:Can steel frame formwork be used for both residential and commercial construction projects?

- Indeed, both residential and commercial construction projects can utilize steel frame formwork. This versatile and enduring solution is applicable to a wide range of projects, encompassing both residential and commercial structures. It ensures exceptional structural stability and can withstand substantial loads, rendering it suitable for extensive endeavors like commercial buildings. Moreover, steel frame formwork provides design flexibility, effortlessly adapting to the distinct specifications of diverse projects, whether they pertain to residential or commercial purposes. Its robustness and durability render it an ideal selection for both types of construction undertakings.

- Q:How is steel frame formwork assembled and disassembled?

- Steel frame formwork is a versatile and durable system used in construction projects to create concrete structures such as columns, walls, and slabs. Assembling and disassembling steel frame formwork involves a series of steps that ensure accuracy, efficiency, and safety. To assemble steel frame formwork, the following steps are typically followed: 1. Preparation: Before starting the assembly, it is important to ensure that the construction site is clean, level, and free from any debris. This helps in providing a stable base for the formwork. 2. Layout and marking: The layout and dimensions of the concrete structure are marked on the ground using chalk lines or other suitable marking tools. This step ensures the correct placement of the steel frame formwork. 3. Aligning and leveling: The steel frames are positioned and aligned according to the marked lines. The frames are then leveled using leveling screws or wedges to ensure a uniform and accurate formwork structure. 4. Connecting the frames: Once the frames are aligned and leveled, they are connected using steel pins or clamps. This provides stability and prevents any movement during the concrete pouring process. 5. Placing the plywood panels: Plywood panels are then fixed onto the steel frames using screws or clips. These panels act as a barrier to hold the concrete in place and provide a smooth finish to the structure. To disassemble steel frame formwork, the following steps are typically followed: 1. Removal of plywood panels: The first step in disassembling the formwork is to remove the plywood panels. This can be done by unscrewing the screws or unclipping the clips that hold the panels in place. 2. Disconnecting the frames: Once the plywood panels are removed, the steel frames can be disconnected. This is done by removing the steel pins or releasing the clamps that hold the frames together. 3. Dismantling the frames: After disconnecting the frames, they can be dismantled by unscrewing or unbolting the frame components. It is important to follow the manufacturer's instructions to ensure safe and efficient dismantling. 4. Cleaning and storage: Once the steel frame formwork is disassembled, it is important to clean and inspect the components for any damage or wear. The components are then stacked and stored in a safe and organized manner for future use. Overall, assembling and disassembling steel frame formwork requires careful planning, precise alignment, and adherence to safety guidelines. Following the correct procedures ensures a successful construction process and allows for reusability of the formwork components.

- Q:Are there any specific considerations for using steel frame formwork in heritage buildings?

- There are a number of important factors to consider when using steel frame formwork in heritage buildings. To begin with, it is crucial to ensure that the existing heritage structure is not damaged by the steel frame formwork. This can be achieved by conducting a thorough structural analysis of the building and designing the formwork accordingly. The formwork must be able to support the weight of the concrete without putting excessive pressure on the heritage structure. Furthermore, the design of the steel frame formwork should take into account any architectural or historical features of the building that need to be preserved. This may include intricate detailing, decorative elements, or unique construction techniques. The formwork should be flexible enough to accommodate these features and ensure their preservation. In addition, it is important to comply with any heritage preservation guidelines or regulations when using steel frame formwork. These guidelines may specify certain materials, techniques, or processes that must be followed in order to protect the integrity of the heritage structure. Consulting with heritage preservation experts, architects, and engineers is essential to ensure that the steel frame formwork meets these requirements. Moreover, the installation and dismantling of the steel frame formwork should be carried out with great care to minimize any potential damage to the heritage building. This may involve using specialized equipment, techniques, or protective measures to prevent accidental impacts or vibrations. Working closely with experienced contractors who have expertise in working with heritage structures is crucial to ensure the safety and preservation of the building. In conclusion, the use of steel frame formwork in heritage buildings necessitates careful consideration of the building's structural, architectural, and historical aspects. By taking these specific factors into account, it is possible to successfully utilize steel frame formwork while preserving the building's integrity and heritage value.

- Q:Are there any specific considerations for using steel frame formwork in coastal areas?

- Yes, there are several specific considerations that need to be taken into account when using steel frame formwork in coastal areas: 1. Corrosion resistance: Coastal areas are prone to high levels of humidity, saltwater exposure, and corrosive environments. Therefore, it is crucial to use steel frames that have high corrosion resistance, such as galvanized or stainless steel. This will ensure the longevity and durability of the formwork system. 2. Material selection: The choice of materials for formwork should be carefully considered for coastal areas. It is important to select materials that can withstand the harsh coastal environment, including saltwater, wind, and sand. Steel frames are a suitable choice due to their strength and resistance to corrosion. 3. Maintenance: Regular maintenance is essential to prevent corrosion and ensure the longevity of steel frame formwork in coastal areas. This includes routine inspections, cleaning, and reapplication of protective coatings as necessary. Proper maintenance will help to extend the lifespan of the formwork system and prevent any potential safety hazards. 4. Anchoring and stability: Coastal areas often experience strong winds and storms, which can put additional loads and stresses on the formwork system. It is crucial to ensure that the steel frames are properly anchored and secured to withstand these forces. Additionally, the formwork system should be designed to have adequate stability and resistance against lateral loads, such as wind or wave action. 5. Environmental considerations: Coastal areas are often environmentally sensitive, with ecosystems that need to be protected. When using steel frame formwork, it is important to consider the impact on the surrounding environment. Measures should be taken to prevent any potential pollution or contamination during the construction process, such as using environmentally friendly coatings or sealants. Overall, while steel frame formwork can be used in coastal areas, it is essential to consider the specific challenges posed by the coastal environment. By selecting the right materials, implementing proper maintenance practices, ensuring stability and anchoring, and considering environmental factors, steel frame formwork can be effectively used in coastal construction projects.

- Q:What are the different types of corner systems available for steel frame formwork?

- There are different types of corner systems available for steel frame formwork, including adjustable corner brackets, multi-functional corner systems, and modular corner systems. These systems are designed to provide flexibility and efficiency in forming corners during the construction process. Adjustable corner brackets allow for easy adjustment of angles, while multi-functional corner systems offer versatility by accommodating various corner configurations. Modular corner systems, on the other hand, provide a pre-engineered solution with standardized components for quick and efficient corner construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords