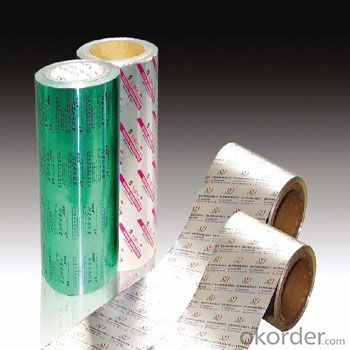

Lacquered Pharmaceutical Foil Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

Application: PTP foil, cold-forming foil, aalu-alu foil

Alloy: 8006/ 8011/ 8079

Temper: H18/O

Thickness& Tolerance: 0.02mm-0.09mm(±6%)

Width& Tolerance: 200mm-1650mm(±1mm)

Lacquer:HSL for PVC

Primer: Primer for printing

Standard: GB/T31988/ASTM-B209/EN546

2.Description

In Europe aluminium experiences high rates of recycling, ranging from 42% of beverage cans, 85% of

construction materials and 95% of transport vehicles.Recycled aluminium is known as secondary aluminium, but maintains the same physical properties as primary aluminium. Secondary aluminium is produced in a wide range of formats and is employed in 80% of alloy injections. Another important use is for extrusion.

White dross from primary aluminium production and from secondary recycling operations still contains useful quantities of aluminium that can be extracted industrially.The process produces aluminium billets, together with a highly complex waste material. This waste is difficult to manage. It reacts with water, releasing a mixture of gases (including, among others, hydrogen, acetylene, and ammonia), which spontaneously ignites on contact with air;contact with damp air results in the release of copious quantities of ammonia

gas. Despite these difficulties, the waste has found use as a filler in asphalt and concrete.

3.Our advantage

We can promise the best quality and quotation!

4.Pictures

5.FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

- Q:STEAMED CHICKEN WITH LEMON BASIL IN BANANA LEAFWhat to prepare:A half of whole ayam kampung, cut into 7 pieces1Fresh lemon basil leaves, to taste21 tomato, cut into 7 slices.2 pieces lime for marinate the chicken4 tbs cooking oil for sauteing Spices paste:1cm/ ? inch of galangal1cm/ ? inch of ginger1cm/ ? inch of turmeric? tsp chili pepper6 cloves of garlic6 cloves of shallotsSeasoning (MSG) to taste? tsp fine salt? tbsp sugar1 tsp grounded candlenuts, For wrapping:Banana leaves for wrapped3Skewers or toothpicks1.You can substitute ayam kampong with Loong kong chicken if you can’t find any, or you can simply use regular chicken as well2.Lemon basil can be substituted with oregano or thyme3.For wrapping, if you can’t find any banana leaf you can use aluminum foil as well

- Your translation is fine except for a few lines and you do not mention what type of vessel the chicken is cooked in or steamed inA half of whole ayam kampung, cut into 7 pieces1 (1 half of a whole ayam kakpung, cut into 7 pieces) Fresh lemon basil leaves, to taste2 (2 fresh lemon Basil leaves or to taste) 1Marinate the chicken with lime, let it stand for a while then clean the chicken 1Marinate the chicken with lime, let it stand for a while (then wipe off the marinade unless you really mean the chicken should be rinsed of the marinade4Prepared the banana leaves for wrappedBefore used, dried or roast the leaves over small flame for few seconds until the leaves is withered4Prepare the banana leaves for wrappingBefore use, dry or roast the leaves over a small flame for few seconds until the leaves is wither(You used the past tense and should use the present tense in this case)

- Q:Right now I have grilled chicken on a baking tray with a sheet of aluminum foil under it, and I didn't grease the foil at all.will it be alright?

- I THINK I would try getting my fiber from foods rich in fiber would probably be best.

- Q:I don't have a cupcake pan or cupcake wrappers, and I can't go to the store and buy anythingI do have a pan thats not flat and has circular indents about 2-3 inches wide and a 1/4 inch deepThe last time I put dough in it, I got what looked like fat cookiesIf I use aluminum foil to make a cup, will it be safe to put in the oven and hold the batter?

- The pan you have is a Madeline pan, for making Madelines which are a type of cake-type cookieWell, old school pioneers used to use their cups to bake inYes, their coffee/tea cupsObviously not the fine china, but their everyday cupsBe sure the cups you use can actually withstand the temperature of the ovenOtherwise they'll shatter, which will make a mess in your ovenAlso be sure you thoroughly grease the inside of the cup or else the cake won't come outI don't think the tinfoil thing will workIt won't be strong enough to hold its shape and will also be very difficult to get the cakes out in one pieceSo barring the cup idea, just go get a muffin-pan and liners from your local storeYou can use a muffin pan for all sorts of things besides cupcakes or muffins you knowThey're great for making mini-meat loaf or giant meat balls (same difference.)

- Q:I have tried putting kerosene in the outside tank, but it was dangerous, the kerosene got all over the place and my clothesWhat kind of container do I need and possible hose in container to pour it safely in the tank without it spilling or splattering all over the place? It has to be a safe pouring method Something u tried yourself and know it worksI am only looking for Questions directed towards my Questions, all others will be reported and ignoredThanks

- YuppersI'm about to do it today for some pork ribsI never cook my ribs higher than 250 degrees Fand if the plastic is approved for microwave cooking, then it will be just fineYou will have nice juicy meat that falls off the bone as the plastic creates a tighter seal and essentially steams the meatJust watch your cooking tempFor chicken.I haven't done that since I cook it at a higher tempgood luck

- Q:I have always been wondering how people get paper cutsI know that the paper cuts them in some way, but i want to know how paper cuts human skinIf it is possible, i would like a long explanation explaining like how, why, etcThank you.

- A paper cut occurs when a piece of paper or other thin, sharp material slices a person's skinPaper cuts, though named from paper, can also be caused by other thin, stiff materials, such as aluminium foil, thin blades of grass, or film negativesAlthough a loose paper sheet is usually too soft to cut, it can be very thin (sometimes as thin as a razor edge), being then able to exert high levels of pressure, enough to cut the skinPaper cuts are most often caused by paper sheets that are strongly fastened together (such as brand new paper out of a ream), because one single paper sheet might be dislocated from the restThus all the other sheets are holding this dislocated sheet in position, and the very small part held away from the rest can be stiff enough to act as a razorPaper cuts can cause surprisingly acute pain since they usually stimulate a large number of skin surface pain receptors (nociceptors) in a very small area of the skinBecause the shallow cut does not bleed very much, the pain receptors are left open to the air, ensuring continued painThis is exacerbated by irritation caused by the fibers in the paper itself, which may be coated in chemicals such as bleachAdditionally, most paper cuts occur in the fingers, which have a greater concentration of sensory receptors than the rest of the bodyThe random orientation of collagen fibers in skin provides the ability to withstand pinpoint forcesHowever, skin does not have the same strength against shearing forces, and is easily cutThe same principle can be applied to performers that stand on blades.

- Q:Me and some friends had this discussion about electromagnetic pulses.I heard two types of rumors about how to protect your electronics on themOne was to turn them completely offThe other was to wrap them in aluminum foil or stick them in a lead laced box.What I would like to know if these rumors hold any water whatsoever?.

- Stand up, and take a standCall the police, or a woman's shelterDon't give up the power you have by being afraid of what your parents may thinkPraying helps, ask God to help youJust don't let him get away with thisTake it from a manSee folks! This is exactly why marriages are failing and where feminist ideology comes from, it's becasue of STUPID MEN LIKE THIS RUINING A DECENT GIRLS LIFE!!!!!!! Scumbag perverts!I bet almost every american woman has a story like this! Used to be a time when relationships were not so complicated, now, this girl will have baggage for the rest of her life, and perhaps bring it into a marriage, and it may end up in divorceand she will get the kids and then another decent man will end up paying child support!

- Q:I just received approval for an RMA on my computer’s motherboard (faulty) and they requested that I package it in an antistatic material, which I have previously thrown awayIs there is another alternative to antistatic material which is cheaper and easier to get? If not, does anyone know the most reliable and quickest store in the UK, selling antistatic material??

- 1yam - the starchy, tuberous root of any of various climbing vines of the genus Dioscorea, cultivated for food in warm regions'Yams are a staple in the diet of many African people.' 2yarrow - a composite plant, Achillea millefolium, of Eurasia, having fernlike leaves and flat-topped clusters of whitish flowers, naturalized in North America'The use of yarrow in folk medicine is based on its apparent anti-inflammatory and coagulatory properties.' 3yawl - a two-masted, fore-and-aft-rigged sailing vessel having a large mainmast and a smaller jiggermast or mizzenmast stepped abaft the sternpost British Dialect: yowl; howl'In the United States yawls are in wide use as yachts'

- Q:Your boat has sunk, but you've made it onto a lifeboatunfortunately, there is no drinking water!how can you purify sea water with:-a transparent plastic sheet -aluminium foil-clothes pegs-a small and large plastic bowl-3 metres of plastic tubing-3 metres metal wire-sticky tapeI really don't know how to do this and need it for triple science work!

- Set up a distiller - small bowl inside larger one, hold it in the middle with wire or clothes pinsPut sheet over the top of the entire setup and make sure its a tight sealPour sea water in outer bowl, it will evaporate and condense on the plastic sheetWeigh the sheet down above the small bowl so the water condensing on the sheet will drip into the bowl.

- Q:I also need the electron configuration diagram and noble gas configuration of magnesium phosphide and aluminum iodide

- NaN MgP AlI not realy sure u can check it up

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lacquered Pharmaceutical Foil Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords