JRS2 series of thermal relay electrical contactors and relays electronic overload relay

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

JRS2-80/Z Thermal Relay

Product Details | |||

Brand Name | Shaman | Item No. | JRS2-80/Z |

Color | Black | MOQ | 100 pcs |

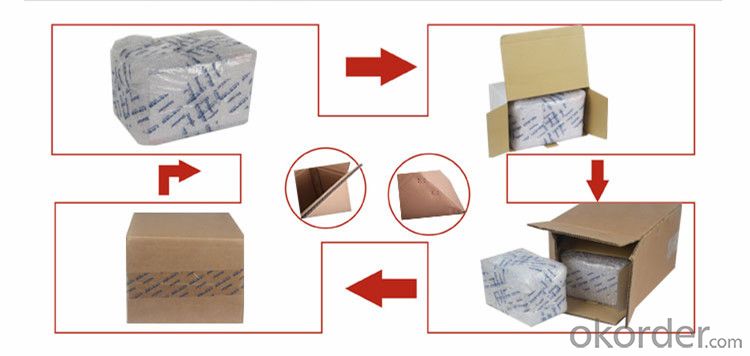

Packing | 30 pcs in one carton based on the items of products. | ||

Important Information | |||

Send sample | Yes | ||

Delivery time | Within 30 days. | ||

Payment terms | T/T 30% deposit, the balance before the shipment. | ||

Introduction:

JRS2 thermal relay is suitable for AC 50/60Hz, voltage up to 660V and current up to 630A,general AC motor of long or discontinuous long operation, used as overload protection and has the functions of breaking phase protection, temperature compensation, and trip indication.

It can automatically and manually get back. It can be fixed with contactor CJX1 together, also be independently fixed.

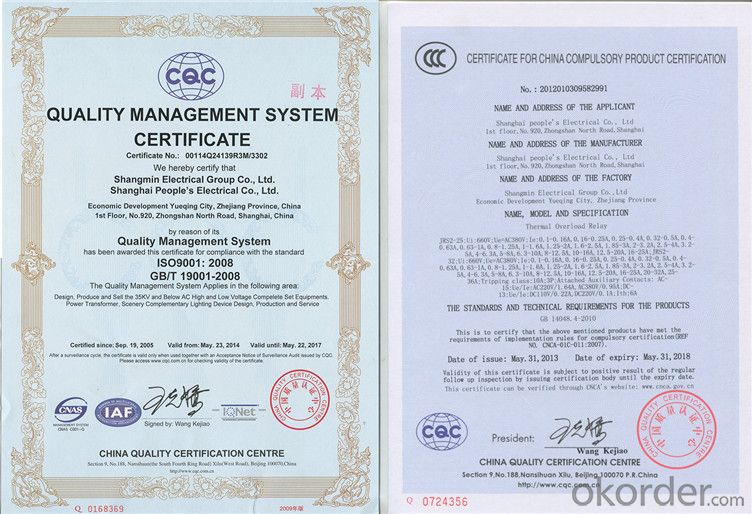

The product conforms to IEC60947-4-1 standard.

Motion Characteristic:

(Three-phase Balance Motion Time)

| No | Times of the setting current | Motion time | Start condition | Ambient temperature | ||

| 1 | 1.05 | >2h | Cold state | 20±5℃ | ||

| 2 | 1.2 | <2h< span=""> | Heat state(Following the No.1 test) | |||

| 3 | 1.5 | <4min< span=""> | ||||

| 4 | 7.2 | 10A | 2s< Tp≤10s | ≤63A | Cold state | |

| 10 | 4s< Tp≤10s | >63A | ||||

Phase-losing Motion Characteristic:

| No | Times of the setting current | Motion time | Start condition | Ambienttemperature | |

| Any two phases | Another phase | ||||

| 1 | 1 | 0.9 | >2h | Cold state | 20±5℃ |

| 2 | 1.15 | 0 | <2h< span=""> | Heat state(Following the No.1 test) | |

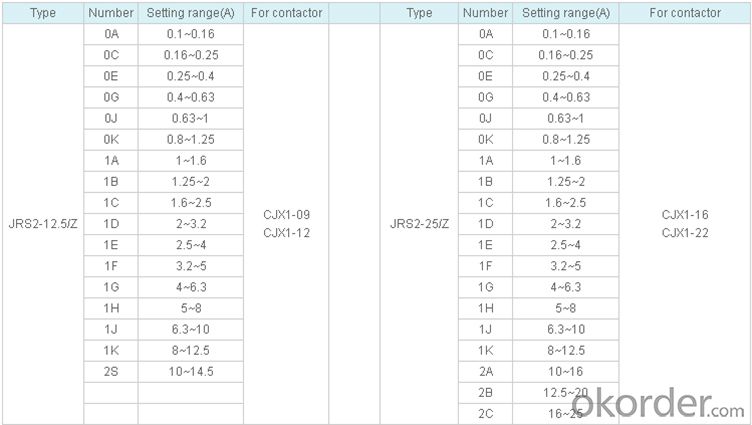

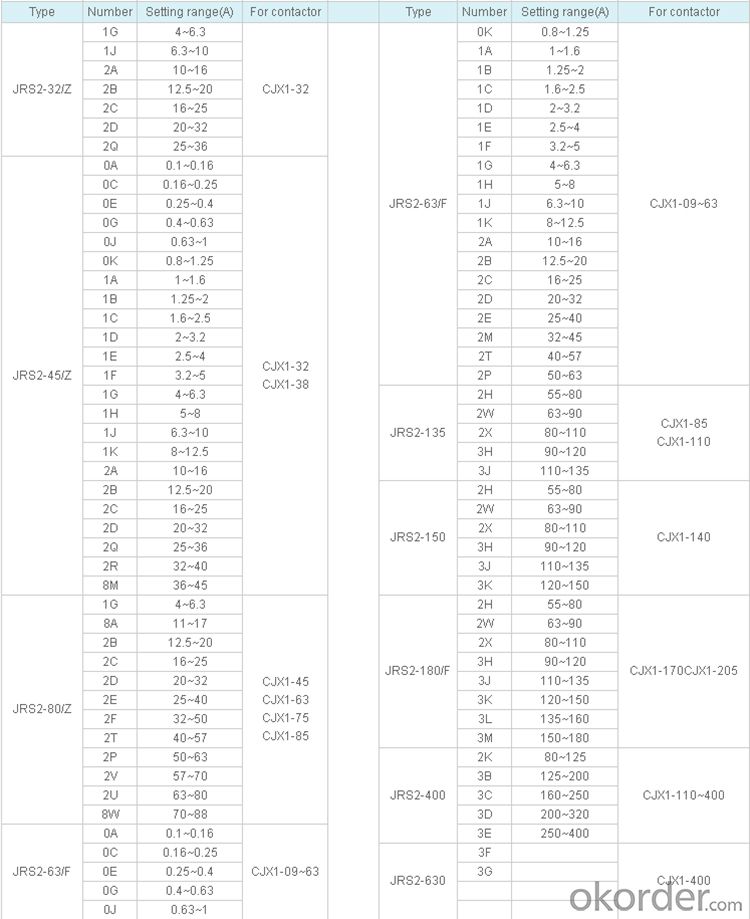

Specification:

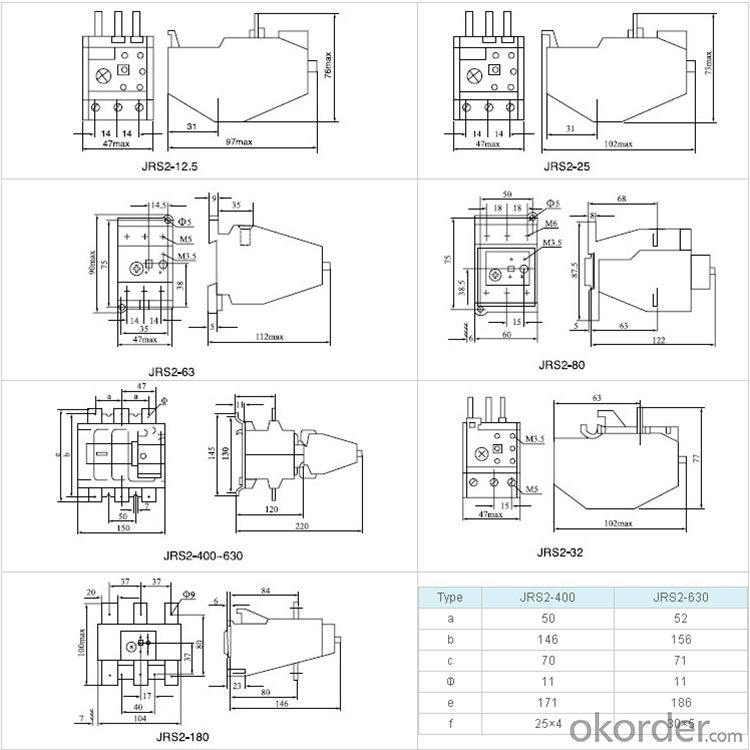

Outline and Mounting Dimension:

Accessories:

Why Chose us:

We have our own engineer teams,will supply the professioanl design for you.

Every new product can be made accurate by your design and demand.

Enough stock to fit your urgently need.

Keep smooth delivery on time.

Perfect package according to your demand.

Our service:

7day*24hours Hot-line & Email Service.

Your inquiry related to our products or prices will be replied in 24hours.

Well-trained and experienced staffs to answer all your questions in fluent English.

OEM&ODM is available.

- Q:What is the speed relay working principle?

- The speed relay works as follows: The speed relay rotor shaft is connected to the axis of the controlled motor and the stator is mounted on the rotor. When the motor rotates, the speed relay rotor rotates, the stator short-circuit conductor will cut the magnetic field, resulting in induced electromotive force, resulting in current. This current generates torque with the rotating rotor magnetic field, and the stator starts to rotate. When the turn to a certain angle, mounted on the stator shaft pendulum to promote the reed action, so that normally closed contact breaking, normally open contact closed. When the motor speed is below a certain value, the torque generated by the stator is reduced and the contact is reset under the action of the spring. Commonly used speed relay with YJ1 type and JFZ0 type. Usually the speed of the relay action speed of 120r / min, reset speed of 100r / min. Turn left to turn right

- Q:1, DC-controlled AC solid-state relay output terminal connected to what is the situation? 2, DC-controlled AC solid-state relay output can not accept the inductive load? Enhanced DC-controlled AC solid-state relays can not be connected to DC output. 3, there can be connected to the inductive load (inductance, need high-speed switching switch) DC-controlled DC solid-state relay? Who is offering a model? TTL control better.

- DC-controlled AC solid-state relays, generally optocoupler + bidirectional thyristor. Thyristor features you should be clear. Direct access to DC, will be out of control! Because the DC is not zero, so once the SCR can not turn off, will continue to go on until the DC power is cut off.

- Q:6ES7 222-1HF22-0XA8 EM222 8 relay 6ES7 222-1BF22-0XA8 EM222 8 out 24VDC, switch volume 6ES7214-2AD23-0XB8 CPU224XP DC / DC / DC, 14DI / 10DO, 2AI / 1AO 6ES7214-2BD23-0XB8 CPU224XP relay output, 14DI / 10DO, 2AI / 1AO 6ES7 223-1BM22-0XA8 EM223 32 in / 32 out 24VDC, switch volume 6ES7 223-1PM22-0XA8 EM223 32 into 24VDC / 32 relay

- The relay is the output of the coil with the power of the contacts closed. The other output is the transistor's electronic switch output. If you want to open a very frequent off, it is recommended to use the transistor out

- Q:I would like to ask: PLC output sub-relay output and thyristor output, what is the difference.I only control the general digital signal, what type should be selected?

- So if you want to high-speed response or need to be smaller, select the transistor unit, if you need a relatively large current on the selection of the relay unit. Generally no special requirements, select the relay unit, wiring and measurement are very convenient, because there is no volume limit so are the terminal block, but the same number of points much larger. Input and output relay is the switch, and the transistor is analog! The switch is in the form of a switch, and the size of the input and output is independent of the switch. Carrying capacity is relatively strong. May drive loads such as relays! While the analog some of the signal amplification, and some of the A / D conversion. It can drive signals such as 1-10V, 4-20mA,

- Q:What is the relay return factor?

- so the relay returns the relay Coefficient has a special requirement, neither too high nor too low.

- Q:Who can explain in detail, what is the difference between electromagnetic relays and intermediate relays, the use of the two is not the same ah, in some cases can be interchangeable

- There is no difference, only the number of contacts enough, the voltage level can be interchangeable

- Q:First note: This question involves professional knowledge, please do not professional mechanical and electrical electronic personnel do not talk nonsense, please answer the question seriously, do not blind copy and paste. The question is prepared to choose the essence of the question and answer, please express your views. If the answer is good, bonus is a small problem. Problem Start: 1: what is the relay, what is the exchange of contactors? What do they have in common and different? 2: What is the role of relays and AC contactors? Relay relay by function which relay, AC contactor by function into what types? 3: Why use air conditioning time relay, why use AC contactor? What are their roles in air conditioning? Requirements: The answer is complete and error-free

- Relay is actually a switch, power to the relay after the coil to produce magnetic field, adsorption contact shrapnel, so that the switch non-stop switch. AC contactor is in fact the same with the original relay, the difference is that the AC contactor is directly connected to the AC, so the current is very large, usually used in large voltage and current are very strong equipment. Relays are usually DC, which is why the relay is soldered to the circuit board. Air conditioning usually need timing, said the relay is a switch, then the relay is to add a general relay time control function, integrated into a relay, so you can control the air conditioning automatically shut down ah, the temperature drop and rise, specifically this is the case La Relays are generally used in household appliances and devices with little voltage and current, while AC contactors are just the opposite, such as large dishwashers. I am selling these products. So the relative or slightly understand the point!

- Q:The type and function of the relay

- The following are the same as the " The role of the relay: as a control element, summed up, the relay has the following effects: 1) to expand the control range: For example, multi-contact relay control signal to a certain value, you can press the contact group of different forms, while switching, breaking, connected to multiple circuits. The following are the same as the " 2) Enlarge: For example, sensitive relays, intermediate relays, etc., with a very small amount of control, you can control the power of the circuit. The following are the same as the " 3) Integrated signal: For example, when a plurality of control signals are input into a multi-winding relay in a prescribed form, the comparison is carried out to achieve a predetermined control effect. The following are the same as the " 4) Automatic, remote control, monitoring: For example, the relay on the automatic device together with other electrical appliances, can be programmed to control the line, in order to achieve automated operation.

- Q:What is the difference between the intermediate relay and the AC contactor

- Commonly used control electrical - AC contactor: In the electrical control circuit, divided into control circuit and the main circuit. AC contactors are the main circuits that are often used to turn on or off the motor or other equipment. Every hour can open and close hundreds of times. In the circuit, often used in conjunction with the button. Reference: International Electrical Network

- Q:What is the general certification of the relay?

- Relay certification are generally: CQC certification, CE certification, TUV certification, UL certification, FCC certification, VDE certification. List: UL is a short description of Underwriter Laboratories Inc. UL safety test is the United States the most authoritative, but also on the community engaged in safety testing and identification of the larger civil institutions. VDE is the German national product logo. VDE testing organization and certification association is the German Institute of Electrical Engineers affiliated institutions, which was established in 1920, as an internationally recognized electronic appliances and their parts safety testing and certification agencies in Europe and the world have enjoyed a high reputation The The "CE" mark is a safety certification mark that is considered a passport for manufacturers to open and enter the European market. Any product marked with the "CE" mark can be sold in the EU member states without having to meet the requirements of each member country, thus achieving the free circulation of goods within the EU member states. FCC certification, also known as the Federal Communications Commission, FCC (Federal Communications Commission) is the United States Federal Communications Commission) in 1934 by COMMUNICATIONACT established by the US government is an independent body, directly responsible to Congress.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JRS2 series of thermal relay electrical contactors and relays electronic overload relay

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords