JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS Equal Angle

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

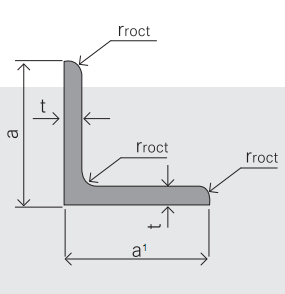

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

6. Material details:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications of JIS Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of JIS Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q:How do steel angles resist bending or deflection?

- Steel angles resist bending or deflection due to their shape and material properties. The design of steel angles, with their L-shaped cross-section, provides structural stability and strength, making them highly resistant to bending or deflection under load. The L-shape of steel angles creates two perpendicular legs, which distribute the applied load more efficiently compared to other shapes. This distribution of load allows the angles to resist bending forces, preventing them from deforming or deflecting significantly. The longer leg of the angle provides greater leverage and stiffness, enhancing its resistance to bending. Moreover, steel itself is a strong and rigid material, known for its high tensile and compressive strength. Steel angles are typically made from hot-rolled steel, which undergoes a process that further improves its structural properties. The combination of the L-shape design and the inherent strength of steel enables steel angles to withstand bending forces without significant deflection. Additionally, steel angles can be reinforced through various methods such as welding or bolting to increase their resistance to bending or deflection. Reinforcements add additional strength and stiffness to the angles, making them even more robust and capable of withstanding higher loads. In summary, steel angles resist bending or deflection due to their L-shape design, the inherent strength of steel, and possible reinforcements. These factors work together to provide structural stability and prevent excessive deformation, making steel angles a reliable choice for various construction and engineering applications.

- Q:What is the purpose of using steel angles in construction?

- Steel angles are commonly used in construction for several purposes. The primary purpose of using steel angles is to provide structural support and stability to various components of a building or structure. These angles are often used to reinforce corners, edges, and joints, adding strength and rigidity to the overall structure. Additionally, steel angles are used to distribute and transfer loads or forces within the construction. They help to evenly distribute the weight and stress across different parts of the structure, preventing any concentrated points of weakness. Moreover, steel angles are versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, allowing for seamless integration into a wide range of construction projects. Furthermore, steel angles offer excellent durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. They can withstand heavy loads, extreme weather conditions, and provide long-lasting support to the structure. In summary, the purpose of using steel angles in construction is to enhance the structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q:How do you determine the load capacity of a steel angle?

- The load capacity of a steel angle is determined by calculating its moment of inertia and considering factors such as material strength, dimensions, and the type of loading it will be subjected to. Additionally, engineering standards and codes provide guidelines for determining load capacities based on these calculations.

- Q:What are the different types of steel angles used in architectural façade systems?

- There are several different types of steel angles that are commonly used in architectural façade systems. These angles serve various purposes and are chosen based on the specific requirements of the project. 1) L-Angles: L-angles are one of the most commonly used types of steel angles in façade systems. They have a 90-degree angle and are often used to create the framework for curtain wall systems. L-angles provide structural support and stability to the façade while also allowing for the attachment of various cladding materials. 2) Z-Angles: Z-angles, also known as Z-bars, are another type of steel angle used in façade systems. They have a Z-shaped profile, with two flanges that are parallel to each other. Z-angles are often used to create horizontal or vertical support members in curtain wall systems, providing additional strength and rigidity. 3) C-Angles: C-angles, also called C-channels or C-beams, are widely used in façade systems for their versatility and strength. They have a C-shaped profile, with a wide base and two flanges that are perpendicular to each other. C-angles are commonly used as support members for cladding panels or as framing elements for architectural features like canopies or sunshades. 4) T-Angles: T-angles, also known as T-bars, have a T-shaped profile and are used in façade systems for various purposes. They can be used as support members for cladding panels, providing a stable base for attachment. T-angles are also used to create mullions or transoms in curtain wall systems, allowing for the integration of windows or glazing units. 5) Unequal Angles: Unequal angles, as the name suggests, have unequal leg lengths. They are used in façade systems when there is a need for uneven or specialized support. Unequal angles are often used to create custom shapes or profiles, allowing architects and designers to achieve unique aesthetic effects or accommodate specific project requirements. Each type of steel angle has its own advantages and applications in architectural façade systems. The choice of angle will depend on factors such as structural requirements, design considerations, and the specific needs of the project.

- Q:Can steel angles be used in bridges?

- Yes, steel angles can be used in bridges. Steel angles are often used as structural elements in bridge construction due to their strength, versatility, and ability to provide support and stability. They can be used in various bridge components such as beams, trusses, and connections, helping to distribute loads and resist forces in bridge structures.

- Q:Can steel angles be used in agricultural buildings?

- Yes, steel angles can be used in agricultural buildings. Steel angles are commonly used in construction due to their durability and structural strength. They can be used for framing, bracing, and reinforcing various parts of agricultural buildings such as roofs, walls, and support structures. Steel angles provide stability and resistance against external forces, making them suitable for the demanding environments often found in agricultural settings.

- Q:How to determine the neutral axis of the angle bar?

- The neutral axis of angle iron or channel steel needs to be calculated, but it can be checked directly.

- Q:Can steel angles be used for manufacturing ladders?

- Indeed, ladders can be manufactured using steel angles. The reason behind their frequent usage in ladder construction lies in their robustness and long-lasting nature. As they provide a solid framework and endure heavy burdens, they prove to be apt for ladder purposes. Moreover, steel angles exhibit resistance against bending and twisting, guaranteeing stability and security during ascent. Furthermore, they can be effortlessly joined together through welding or bolting to form the desired ladder structure. All in all, steel angles serve as a dependable option for ladder manufacturing.

- Q:How do you cut steel angles to size?

- To cut steel angles to size, there are several methods you can use depending on the tools available to you. Here are a few common approaches: 1. Using an Angle Grinder: An angle grinder is a versatile tool that can be used to cut steel angles. Ensure you have a cutting disc suitable for metal cutting attached to the grinder. Measure and mark the desired length on the angle, then securely clamp it down. Using the grinder, carefully follow the marked line, applying even pressure to cut through the steel. Take necessary safety precautions, such as wearing protective eyewear and gloves, and be aware of any sparks produced during the cutting process. 2. Utilizing a Bandsaw: If you have access to a bandsaw, it can be an efficient tool for cutting steel angles. Ensure the bandsaw is equipped with a blade specifically designed for metal cutting. Securely clamp the angle, aligning the marked line with the blade's path. Start the bandsaw and slowly feed the angle into the blade, maintaining a steady pace to achieve a clean cut. 3. Using a Hacksaw: Although it may be a slower process, a hacksaw can also be used to cut steel angles. First, securely clamp the angle to a workbench or vise. Use a square to mark a straight cutting line on the angle, then carefully saw along the line. Apply steady pressure while sawing to maintain control and achieve a clean cut. Remember to use a blade suitable for cutting metal and take breaks if needed to avoid fatigue. Regardless of the method you choose, it is crucial to take safety precautions, such as wearing appropriate protective gear and ensuring the work area is clear and well-ventilated. Additionally, always double-check measurements and use proper techniques to achieve accurate cuts.

- Q:Can steel angles be used for staircases or handrails?

- Yes, steel angles can be used for staircases or handrails. Steel angles provide structural support and can be used to create sturdy and durable staircases and handrails. They are commonly used in construction for their strength and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

JIS Equal Angle Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords