Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-dip Galvanized Steel Description:

Hot-dip Galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process.Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of Hot-dip Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

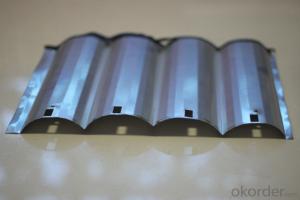

3. Hot-dip Galvanized Steel Images

4.Hot-dip Galvanized Steel Specification

Standard: ASTM A653M,EN10327,JIS G 3302

Grade: CS, DX51D+Z,SGCC

Thickness: 0.15mm~3.5mm

Width: 1250,600-1250mm

Coil weight:3-10 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Hot-dip Galvanized Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q:Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Polyurethane foam can only achieve B1 flame retardant, the system's fire resistance by the two sides of the composite material fire resistance decision.

- Q:50mm thick color steel rock wool sandwich board price is generally how much

- 50 thick rock wool color plate prices according to the rock wool core material and the thickness of the panel thickness and quality parameters are closely related! But the general quality of a little bit almost 50 thick rock wool color plate price of about 40 yuan / m or so Medium quality 50 thick color steel rock wool sandwich panel price of about 55 yuan / m or so Good quality 50 thick color steel rock wool sandwich board price of about 65 yuan / m But the above price information is estimated, the specific price or suggest that you consult a professional Hongxin source belongs to the Shandong region of a 50-thick rock color steel plate

- Q:50mm thick insulation color steel sandwich board with J * B42-333 * 1000 What does this mean?

- 42 for the high corrugated slope, 333 for the distance between the center of the slope, 1000 for the practical area, this sandwich panel is not common

- Q:Is polystyrene sandwich board flammable?

- In general, the benzene board is flammable, but there is a flame retardant type, is the type of self-extinguishing. Usually used as building materials. The other is basically flammable.

- Q:100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q:Want to buy sandwich panels, where there are good manufacturers?

- I have to tell you, Zhejiang Bo Ya building materials is a relatively well-known domestic one, where their sales quite big, with two or three decades of production experience, technology, equipment are more advanced, so buy sandwich board to them where Yes, good quality is also cheap

- Q:The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

- Q:What is the thickness of the upper and lower panels of the rock wool sandwich panel? Is there any provision in national standard?

- You said that if it is a fire isolation belt, it is generally 1-2cm bar if it is color plate, commonly used 0.4--1.6 mm to see the overall length of it

- Q:Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Normal concrete beam span of not more than 5 meters, or the volume of the beam to do very exaggerated. So use a lightweight architecture It is understood that foreign general steel truss girder, but also useful wood beams under the steel truss.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Galvanized Steel Coil for Dry-wall Inside Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords