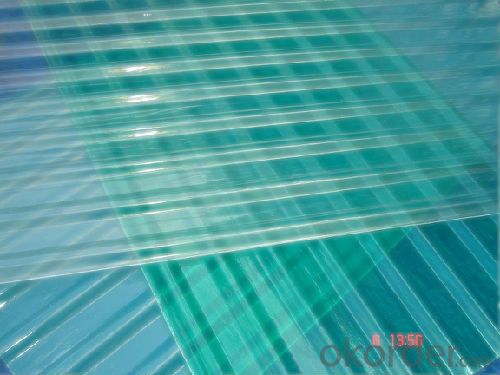

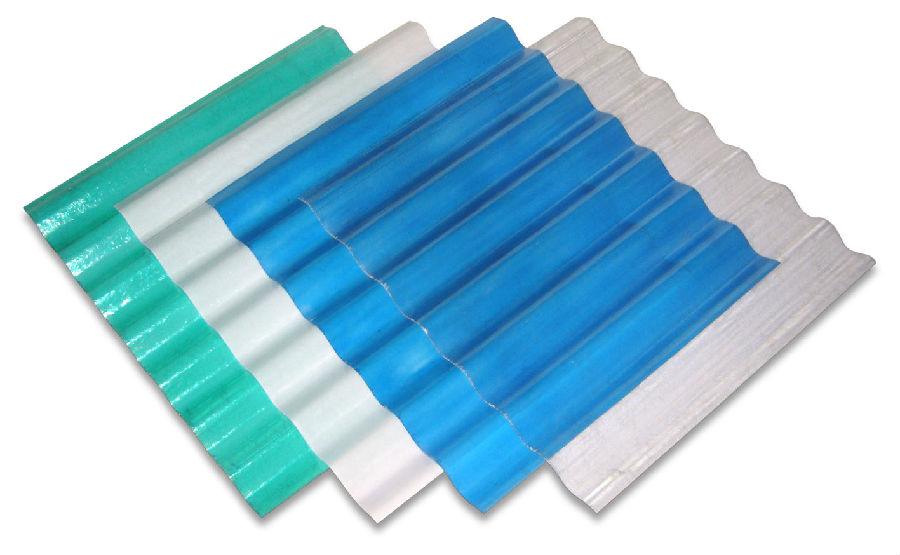

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Fibreglass sheet,FRP panels,fibreglass panel,corrugated sheet can be used in many kinds of fileds such as building etc.It includes transparent ,lightblue ,red and other colors.

2.Characteristics

1)High light transparency

2)Light weight and high strength

3)Corrosion and impact resistance

4)Anti-UV, anti-static, insulation

5)Accurate cross-section size

6)The length of the random cutting and more

7)Widely used in industrial plants, large-scale treasury markets, greenhouse, aquaculture and tourism

8)Used as roof, wall panel and more

9)Supports good lighting effect

3.Technical Data Sheet

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

Warranty:15 years

Item | Data | Reference | Item | Data | Reference |

Tensile modulus(Gpa) | 6.92 | GB | catalyst cold temperature | -52 | GB |

tensile strength(Gpa) | 103 | GB | heat distortion temperature | 172 | GB |

flexural modulus(Gpa) | 6.00 | GB | glass fiber content | above30% | GB |

flexural strength(Gpa) | 171 | GB | water absorption% | 0.18 | GB |

shear strength(Gpa) | 89.9 | GB | specific gravity | 1.48g/cm² | GB |

Barcol hardness | 47 | GB | Coefficient of thermal expansion | 1.5-2.2*10-5 | GB |

4.FAQ

a.Delivery Time: The products will be ready in 10-15 days after getting the advance payment or LC.

b.Payment Term:30% T/T in advance,70% againest B/L copy or LC.

- Q:Are FRP roofing panels prone to warping from heavy machinery?

- The durability and resistance to warping of FRP roofing panels are well-known. However, exposure to heavy machinery may result in warping, depending on various factors. To begin with, the resistance to warping of FRP roofing panels is greatly influenced by their thickness and quality. Thicker panels with a higher fiberglass content are less likely to warp under heavy machinery loads compared to thinner or lower-quality panels. Additionally, the type and weight of the heavy machinery can affect the probability of warping. While FRP panels can withstand normal loads like snow or wind, excessive weight from heavy machinery can surpass their load-bearing capacity and potentially cause warping. Moreover, the condition of the underlying support structure is crucial. If the structure is weak or incapable of handling the weight of heavy machinery, it can create localized pressure points on the FRP panels, increasing the risk of warping. Proper installation is also vital in preventing warping. Inadequate fastening of the panels or gaps and uneven pressure distribution during installation can contribute to warping, particularly under heavy machinery loads. To minimize the possibility of warping, it is advisable to seek guidance from a professional roofing contractor with expertise in FRP installations. They can evaluate the specific requirements of the roofing project, taking into account the type and weight of machinery involved, and recommend suitable panel thickness, quality, and installation techniques to ensure maximum durability while minimizing the risk of warping.

- Q:Are FRP roofing panels fire-resistant?

- Indeed, FRP (Fiberglass Reinforced Plastic) roofing panels possess fire-resistant qualities. Their composition comprises a blend of fortified fiberglass and plastic resin, endowing them with superb resistance against fire. These panels boast a substantial ignition temperature and do not emit any noxious or detrimental fumes when subjected to flames. Furthermore, FRP roofing panels have the ability to self-extinguish, ceasing to burn once the fire's origin is eliminated. Consequently, they serve as a secure option for roofing purposes, especially in regions prioritizing fire safety.

- Q:Can FRP roofing panels be painted?

- Yes, FRP roofing panels can be painted. However, it is important to use a paint that is specifically designed for use on FRP surfaces, as regular paint may not adhere properly. Additionally, proper surface preparation and cleaning should be done prior to painting to ensure the best results.

- Q:Do FRP roofing panels require edge trims or flashing?

- Yes, FRP roofing panels do require edge trims or flashing. These components are necessary to provide a proper seal and protection against water infiltration at the edges of the panels. Additionally, edge trims and flashing help to enhance the aesthetic appearance and overall durability of the FRP roofing system.

- Q:Can FRP roofing panels be used for sunrooms or conservatories?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for sunrooms or conservatories. FRP panels are lightweight, durable, and offer excellent light transmission, making them a suitable choice for these applications. Additionally, FRP panels are resistant to UV rays and can withstand various weather conditions, making them ideal for outdoor structures like sunrooms or conservatories.

- Q:Can FRP roofing panels be used for both residential and commercial skylights?

- FRP roofing panels are indeed applicable for skylights in both residential and commercial purposes. These panels possess remarkable traits such as being lightweight, durable, and having exceptional light transmission capabilities, which render them perfect for skylights in residential and commercial environments alike. They exhibit resistance towards UV rays, weathering, and impacts, thereby guaranteeing enduring performance and reduced upkeep. Furthermore, these FRP panels offer customization options regarding size, shape, and color in order to accommodate various design preferences and meet the precise specifications of any residential or commercial skylight undertaking.

- Q:Can FRP roofing panels be used for public transportation stations or terminals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for public transportation stations or terminals. FRP panels are a popular choice for various construction applications due to their durability, strength, and resistance to corrosion and weathering. These panels are lightweight and easy to install, making them suitable for public transportation stations or terminals where quick installation is essential. Additionally, FRP panels can be designed to provide excellent insulation and noise reduction, contributing to the comfort of the individuals using the transportation facilities. Overall, FRP roofing panels are a viable option for public transportation stations or terminals, offering a cost-effective and reliable solution.

- Q:Are FRP roofing panels suitable for healthcare or medical facilities?

- FRP (Fiberglass Reinforced Plastic) roofing panels are indeed suitable for healthcare or medical facilities. These panels offer a range of benefits that make them an excellent choice for such environments. First and foremost, FRP panels are highly durable and resistant to corrosion, which is vital for maintaining a sanitary and hygienic atmosphere in medical settings. They are also resistant to mold, mildew, and bacteria growth, which is essential for preventing the spread of infections and maintaining a healthy environment for patients and staff. Furthermore, FRP roofing panels are lightweight and easy to install, which can be advantageous when retrofitting or renovating existing medical facilities. Their lightweight nature reduces the strain on the building structure and decreases the installation time, minimizing disruption to the facility's operations. Additionally, FRP panels are available in various colors and finishes, allowing for customization to match the aesthetic requirements of the healthcare facility. Moreover, FRP roofing panels provide excellent light transmission, which is crucial for healthcare settings as it promotes natural lighting and reduces the reliance on artificial lighting. Natural light has been proven to enhance healing and improve the overall well-being of patients, while also positively impacting the working environment for medical professionals. Lastly, FRP panels are cost-effective and have a long lifespan, making them a practical choice for healthcare facilities where budget constraints are a consideration. Their durability and low maintenance requirements contribute to reduced long-term costs associated with roof repairs and replacements. In conclusion, FRP roofing panels are highly suitable for healthcare or medical facilities due to their durability, resistance to corrosion and microbial growth, ease of installation, customization options, light transmission properties, and cost-effectiveness. These panels provide a reliable roofing solution that meets the specific requirements of medical settings, ensuring a safe, sanitary, and aesthetically pleasing environment for patients and healthcare professionals.

- Q:Can FRP roofing panels be used for covered parking structures or garages?

- Yes, FRP roofing panels can be used for covered parking structures or garages. FRP panels are known for their durability, resistance to weathering, and ability to withstand heavy loads. They are also lightweight, making them a suitable choice for such structures. Additionally, FRP panels can provide UV protection, which is essential for parking areas exposed to sunlight. Overall, FRP roofing panels are a reliable option for covered parking structures or garages.

- Q:Can FRP roofing panels be used in earthquake-prone areas?

- FRP roofing panels are suitable for use in areas prone to earthquakes. These panels are recognized for their robustness, longevity, and ability to withstand various environmental factors, including seismic activity. They are specifically engineered to endure strong winds, heavy rainfall, and earthquakes. Utilizing FRP roofing panels in earthquake-prone areas presents numerous benefits. Firstly, these panels are lightweight, reducing the overall structural load on buildings. This aids in minimizing the impact of seismic forces on the foundation and structure of the building. Secondly, FRP panels possess high tensile strength, enabling them to withstand the stress and movement caused by earthquakes. Their flexibility allows them to absorb and distribute seismic energy, lowering the risk of damage or collapse. Additionally, FRP panels exhibit exceptional impact resistance, a critical characteristic in areas susceptible to earthquakes where debris and falling objects can cause substantial harm. Moreover, FRP panels are non-corrosive and possess a long lifespan, making them an ideal choice for earthquake-prone regions. They do not rust or deteriorate over time, ensuring durability and reliability during seismic events. It is essential to acknowledge that the installation and design of FRP roofing panels in earthquake-prone areas must comply with local building codes and regulations. Adequate structural support and appropriate anchoring methods are crucial to optimize the performance and safety of FRP roofing panels during seismic events. In conclusion, FRP roofing panels can effectively be utilized in earthquake-prone areas, offering a resilient and dependable roofing solution capable of withstanding the challenges presented by seismic activity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords