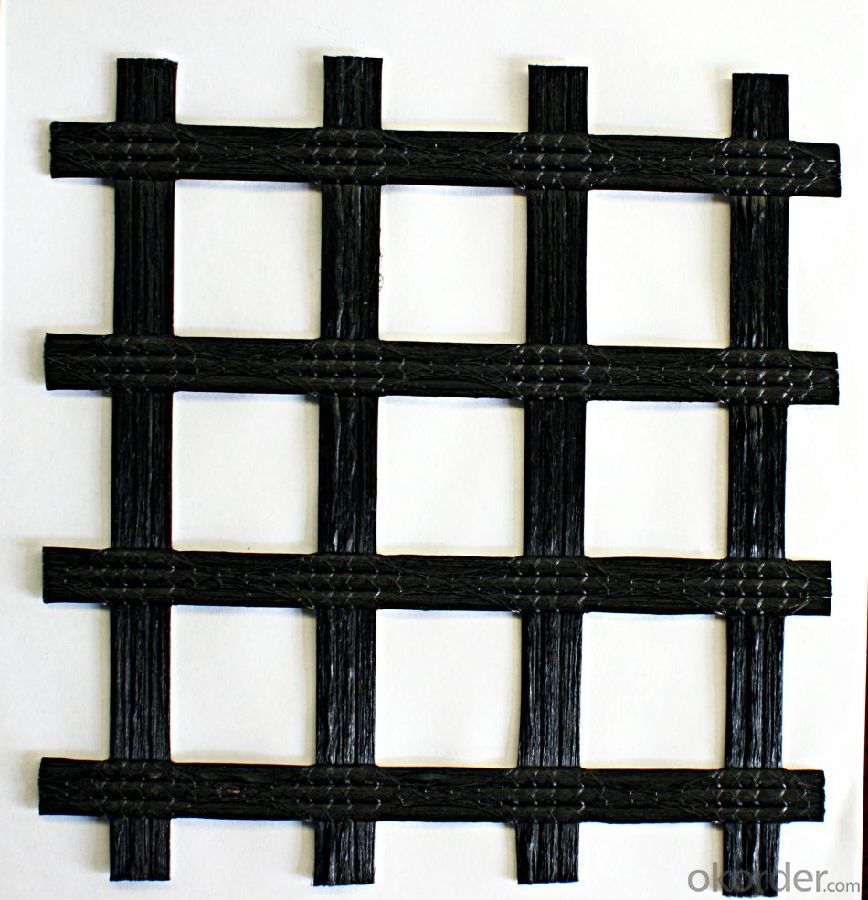

High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Polyester Geogrid known as PET Grid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

PET Grid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How do geogrids improve the performance of reinforced slopes?

- Geogrids improve the performance of reinforced slopes by providing additional stability and strength to the soil structure. They act as a reinforcement material, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids also distribute the applied loads more evenly, reducing the potential for deformation and settlement. Overall, geogrids enhance the slope's resistance to erosion, improve slope stability, and increase the longevity and durability of the reinforced structure.

- Q:Can geogrids be used in subgrade improvement?

- Yes, geogrids can be used in subgrade improvement. Geogrids are often used in civil engineering projects to reinforce and stabilize weak soils in the subgrade. They can help to distribute loads more evenly, increase bearing capacity, and reduce settlement. Additionally, geogrids can improve the overall performance and longevity of the subgrade, making them a valuable tool in subgrade improvement projects.

- Q:Who can elaborate on the highway construction steps, as well as laying materials, the more detailed the better!!!

- The specifications are as follows: Geogrid TGDG25 TGDG35 TGDG50 TGDG80 TGDG110 TGDG120 TGDG150 width of 1 meters -3 meters; bidirectional geogrid TGSG20-20 width 2.5-5m TGSG15-15 TGSG25-25 TGSG30-30 TGSG40-40 GS30-30 GS50-50 m; plastic composite grid GS60-60 GS80-80 GS80-60 GS150-150 width 4-6m meters; BJG35-35 BJG50-50 BJG60-60 BJG80-80 glassgrid width 4-6 meters;

- Q:How do geogrids prevent cracking in asphalt pavements?

- Geogrids prevent cracking in asphalt pavements by providing reinforcement and stability to the pavement structure. They are installed between the layers of asphalt and act as a structural support, distributing the load more evenly across the pavement surface. This helps to reduce the stress and strain on the asphalt, preventing cracking and extending the lifespan of the pavement.

- Q:What are the benefits of using geogrids in roadways?

- The benefits of using geogrids in roadways are numerous. Firstly, geogrids provide reinforcement to the road surface, increasing its strength and stability. This helps in preventing the formation of cracks and potholes, leading to longer-lasting and more durable roads. Secondly, geogrids help in distributing the load from vehicular traffic more evenly, reducing the stress on the road and preventing premature deterioration. Additionally, geogrids improve the overall performance of the road by enhancing its resistance to rutting, erosion, and other forms of pavement distress. Moreover, geogrids can reduce construction costs by reducing the amount of aggregate required for road construction. Overall, the use of geogrids in roadways improves their longevity, reduces maintenance needs, and enhances the safety and comfort of road users.

- Q:High density polyethylene one-way geogrid, tensile yield of 20kn/m

- Material is high density polyethylene material

- Q:Definition of GeotextilesWhat are what material, what role

- Nonwoven geotextile:A non-woven cloth is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the use requirements, non-woven geotextile fabric has good clearance, good adhesion, because the soft fiber has certain anti tear ability and ability to adapt to the deformation of good, and has good drainage capacity of plane surface, soft multi gap has good friction coefficient can increase the soil particle etc. the ability of adhesion, can prevent fine particles by preventing particulate loss and eliminate excess water, soft surface protection ability is very good. In accordance with the length of wire is divided into non-woven geotextile filament or staple nonwoven geotextile. The utility model has the advantages of good filtration, isolation, reinforcement, protection, etc. the utility model is a wide application of geosynthetics, and the tensile strength of the filament is higher than that of the short filament, which can be selected according to the specific requirementsWoven geotextile (reinforced geotextile):

- Q:What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement helps improve the stability and load-bearing capacity of geogrids by restraining lateral movement and enhancing soil-geogrid interaction. It prevents the geogrid from elongating or deforming under heavy loads, leading to better reinforcement and increased structural integrity. Confinement also reduces the potential for geogrids to slip or creep, improving their long-term performance and durability.

- Q:Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. Geogrids are often employed in these scenarios to stabilize soil and prevent erosion until more permanent erosion control measures can be implemented. They are effective in reinforcing and stabilizing the soil, reducing the likelihood of erosion, and providing temporary erosion control solutions.

- Q:How do geogrids help in reducing construction equipment requirements?

- Geogrids help in reducing construction equipment requirements by providing soil stabilization, reinforcement, and confinement. They distribute the load across a wider area, reducing the need for heavy machinery and excavation. This results in cost savings, less fuel consumption, and faster construction processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords