High Performance Ladle Slide Gate for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

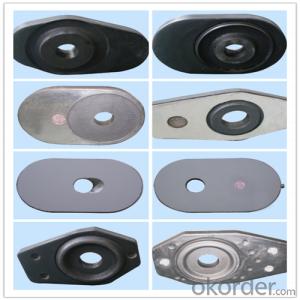

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

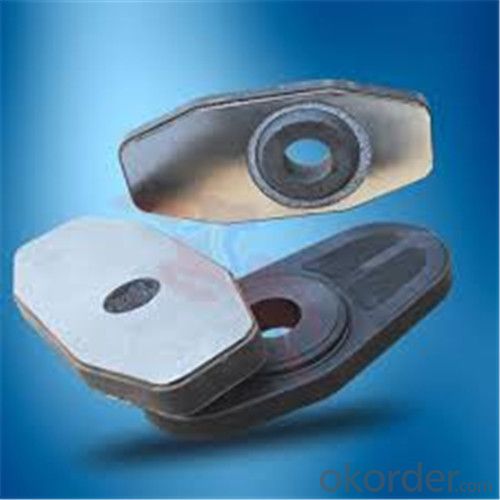

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

About us

Sample is on your request.

Welcome to visit our factory~

- Q:What are the considerations for repairing and patching monolithic refractories?

- When it comes to the repair and patching of monolithic refractories, there are several key factors that must be taken into consideration. First and foremost, it is crucial to thoroughly evaluate the extent and severity of the damage or deterioration. This assessment will help determine the most appropriate repair method and materials required. Minor cracks or small damages may only necessitate a simple patch or seal, whereas larger or more serious damage may require a complete replacement or a more extensive repair process. Secondly, the type of monolithic refractory material being utilized is a critical factor to consider. Different types of monolithic refractories possess varying properties and characteristics, such as thermal conductivity, chemical resistance, and mechanical strength. Therefore, it is vital to select a repair material that is compatible with the existing refractory material, ensuring proper bonding and optimal performance. Another factor to take into account is the operating conditions and environment in which the monolithic refractory is exposed. Variables such as temperature, pressure, chemical exposure, and abrasion can significantly impact the durability and longevity of the refractory material. Understanding these conditions will assist in selecting the appropriate repair materials and techniques that can withstand and perform well under these specific circumstances. Furthermore, it is imperative that the repair process is carried out by experienced personnel who possess knowledge about refractory materials and their installation. Improper repairs can lead to further damage or diminished performance, so it is essential to have skilled professionals who can execute the repair work correctly. Lastly, regular inspection and maintenance of the monolithic refractories are crucial in order to detect any potential damage or deterioration early on. Timely repairs and patching can prevent further deterioration and prolong the service life of the refractory material. In summary, the considerations for repairing and patching monolithic refractories involve evaluating the extent of damage, selecting compatible repair materials, understanding the operating conditions, employing skilled personnel, and conducting regular inspections and maintenance. By taking these factors into account, one can ensure effective repairs and the continued performance of monolithic refractories.

- Q:What are the specific requirements of monolithic refractories for ladle purging applications?

- The specific requirements of monolithic refractories for ladle purging applications include high thermal shock resistance, excellent erosion resistance, good slag resistance, and low porosity. Thermal shock resistance is crucial in ladle purging applications as the refractory material needs to withstand rapid temperature changes without cracking or spalling. This is particularly important during ladle purging, where the ladle is exposed to high temperatures during molten metal pouring and then quickly cooled down during purging. Erosion resistance is another important requirement for monolithic refractories in ladle purging applications. The refractory material should be able to withstand the erosive action of molten metal streams and metalloids during purging. It should have a high resistance to chemical attack, preventing the material from deteriorating or eroding away. Slag resistance is also necessary for monolithic refractories used in ladle purging. The refractory material should have good resistance to the corrosive effects of slag, which can be present in ladles during purging. Slag can cause chemical reactions that can degrade the refractory material, leading to premature failure. Low porosity is an essential requirement for monolithic refractories in ladle purging applications. Low porosity ensures that the refractory material is impermeable to molten metal, preventing it from infiltrating the material and causing damage. This also helps to maintain the integrity and performance of the refractory lining during ladle purging. Overall, monolithic refractories for ladle purging applications need to exhibit high thermal shock resistance, excellent erosion resistance, good slag resistance, and low porosity to ensure the durability and longevity of the refractory lining in ladles during purging operations.

- Q:What are the advantages of using insulating castables in the iron and steel industry?

- There are several advantages of using insulating castables in the iron and steel industry. Firstly, insulating castables provide excellent thermal insulation. They have low thermal conductivity, which helps to minimize heat loss from the furnaces and other equipment. This is particularly important in the iron and steel industry, where high temperatures are required for various processes. The insulation provided by castables helps to maintain a stable temperature within the furnace, resulting in improved energy efficiency and reduced fuel consumption. Secondly, insulating castables have high strength and excellent resistance to thermal shock. This is crucial in the iron and steel industry, where extreme temperature changes are common. The castables can withstand rapid heating and cooling cycles without cracking or compromising their structural integrity. This ensures the longevity and durability of the refractory lining, reducing the need for frequent maintenance and repairs. Furthermore, insulating castables are lightweight and easy to install. Their low density makes them easier to handle and transport, resulting in reduced labor costs and shorter installation times. This is particularly advantageous in large-scale iron and steel plants, where time and cost efficiency are critical. Moreover, insulating castables offer good corrosion resistance. The harsh environment in the iron and steel industry, with the presence of molten metal, slag, and various chemicals, can cause corrosion and erosion of refractory materials. Insulating castables are designed to withstand these corrosive conditions, ensuring the longevity of the lining and minimizing the risk of downtime and production disruptions. Lastly, insulating castables are versatile and can be customized to meet specific requirements. They are available in various compositions and densities, allowing for tailored solutions to different applications within the iron and steel industry. This versatility ensures optimal performance and efficiency in various furnace and equipment designs. In conclusion, the advantages of using insulating castables in the iron and steel industry include excellent thermal insulation, high strength, resistance to thermal shock, lightweight installation, corrosion resistance, and versatility. These benefits contribute to improved energy efficiency, reduced maintenance costs, increased durability, and enhanced overall productivity in the industry.

- Q:How do monolithic refractories contribute to the overall efficiency of ladle slagging operations?

- Monolithic refractories play a vital role in enhancing the overall efficiency of ladle slagging operations, which involve removing impurities from molten metal in a ladle before pouring it into molds or further processing. One of the primary benefits of monolithic refractories is their capacity to withstand high temperatures, a crucial factor in ladle slagging operations. The refractory lining in the ladle must endure the intense heat generated by the molten metal and slag, as well as the chemical reactions occurring during the process. By possessing high thermal stability, monolithic refractories prevent the lining from cracking or deteriorating, thus ensuring the integrity of the ladle and maintaining its efficiency. Furthermore, monolithic refractories offer excellent resistance against chemical erosion and corrosion. In the ladle slagging process, the molten metal and slag may contain impurities and aggressive chemicals such as sulfur, phosphorus, and other oxides. These substances can attack and degrade the lining of the ladle, compromising its efficiency. However, monolithic refractories are specifically designed to withstand these chemical attacks, thereby prolonging the lifespan of the ladle and reducing the need for frequent repairs or replacements. Moreover, monolithic refractories possess exceptional thermal insulation properties. Precise temperature control is essential in ladle slagging operations to facilitate desired chemical reactions and efficient impurity removal. The thermal insulation provided by monolithic refractories helps maintain a consistent temperature within the ladle, preventing heat loss and facilitating optimal slagging conditions. Additionally, this insulation minimizes energy consumption and improves the overall energy efficiency of the ladle slagging process. In conclusion, monolithic refractories make significant contributions to the overall efficiency of ladle slagging operations. Their ability to endure high temperatures, resist chemical erosion, and provide thermal insulation ensures the integrity and longevity of the ladle. By reducing the need for frequent repairs and enabling precise temperature control, monolithic refractories optimize the slagging process, leading to enhanced productivity and cost-effectiveness.

- Q:How do monolithic refractories perform in blast furnace taphole applications?

- Monolithic refractories perform excellently in blast furnace taphole applications due to their high thermal resistance, mechanical strength, and resistance to chemical attack. They are able to withstand the extreme temperatures and abrasive conditions of the blast furnace discharge, ensuring reliable and efficient operation of the taphole. Additionally, monolithic refractories offer easy installation and maintenance, reducing downtime and improving overall productivity in the blast furnace.

- Q:What are the common testing methods used to evaluate the performance of monolithic refractories?

- The common testing methods used to evaluate the performance of monolithic refractories include thermal conductivity testing, hot modulus of rupture testing, abrasion resistance testing, thermal shock resistance testing, and corrosion resistance testing.

- Q:How do monolithic refractories improve the performance of ladles and tundishes?

- Monolithic refractories improve the performance of ladles and tundishes by providing superior thermal insulation, high mechanical strength, and resistance to chemical attacks and thermal shocks. These qualities enhance the overall durability and longevity of the ladles and tundishes, reducing the need for frequent repairs or replacements. Additionally, monolithic refractories offer better flow properties, facilitating smooth and efficient pouring of molten metal, while minimizing the risk of slag or metal infiltration. Overall, the use of monolithic refractories improves the efficiency, productivity, and cost-effectiveness of ladles and tundishes in various industrial applications.

- Q:How do monolithic refractories perform in rotary kiln applications?

- Monolithic refractories perform exceptionally well in rotary kiln applications due to their high thermal shock resistance, excellent chemical resistance, and superior strength at high temperatures. Their ability to withstand extreme heat and harsh chemical environments makes them ideal for lining the interior of rotary kilns. Additionally, monolithic refractories offer easy installation and maintenance, ensuring efficient and reliable kiln operations.

- Q:How do monolithic refractories withstand thermal shock?

- Monolithic refractories are able to withstand thermal shock due to their unique properties and composition. Thermal shock occurs when there is a rapid change in temperature, causing stress and potential damage to the refractory material. However, monolithic refractories are designed to have high thermal shock resistance, and this is achieved through several mechanisms. Firstly, the composition of monolithic refractories includes materials with low thermal expansion coefficients. This means that they have a minimal change in size or volume when exposed to different temperatures. This property allows the refractory material to withstand thermal shock by minimizing the stress caused by temperature fluctuations. Secondly, monolithic refractories have excellent thermal conductivity. This property allows them to efficiently transfer heat away from the hot areas, preventing localized overheating and reducing the risk of thermal shock. The rapid dissipation of heat helps to maintain a more uniform temperature distribution within the refractory material, thus reducing the chances of cracking or spalling. Additionally, the binding agents used in monolithic refractories play a crucial role in their thermal shock resistance. These binders provide strength to the refractory material and help to maintain its integrity during thermal cycling. The binders also contribute to the refractory's resistance to thermal shock by reducing the permeability of the material, preventing the penetration of hot gases or liquids that could cause damage. Moreover, the installation technique of monolithic refractories is an important factor in their ability to withstand thermal shock. Monolithic refractories are typically applied as a single, continuous layer, eliminating the joints and seams that can be weak points in other refractory systems. This seamless installation method ensures better thermal shock resistance as there are no weak points for cracks to propagate. In summary, monolithic refractories withstand thermal shock through a combination of factors including their low thermal expansion coefficients, high thermal conductivity, suitable binding agents, and seamless installation techniques. These properties and design considerations allow monolithic refractories to effectively handle rapid changes in temperature and maintain their structural integrity, making them ideal for applications that involve thermal cycling and extreme temperature variations.

- Q:What are the key properties of monolithic refractories?

- Monolithic refractories, which lack a definite form like bricks or tiles, are a type of refractory material. They are typically composed of a mixture of aggregates, binders, and additives that can be easily molded and installed in various industrial applications. The main characteristics of monolithic refractories include: 1. Exceptional heat resistance: Designed to endure extremely high temperatures, monolithic refractories are suitable for industries such as steel, cement, glass, and petrochemicals. They can maintain their strength and structural integrity even at temperatures exceeding 3000 degrees Fahrenheit. 2. Ability to withstand thermal shock: Monolithic refractories possess the capacity to resist sudden temperature changes, which can cause cracking or damage to the refractory. This property is crucial in environments where rapid heating or cooling occurs, such as furnaces or kilns. 3. Resistance to chemical attack: Monolithic refractories display excellent resistance to corrosion from molten metals, slag, gases, and other harsh substances. This makes them ideal for environments where contact with acidic or alkaline materials is common. 4. Low porosity: Monolithic refractories have low porosity, meaning they have a high density and are less permeable to gases and liquids. This property ensures that molten metals or corrosive substances cannot easily penetrate the refractory, contributing to its longevity and performance. 5. Easy installation and repair: Unlike traditional refractory materials like bricks, monolithic refractories can be easily molded and installed in various shapes and sizes. They can be applied using techniques such as spraying, casting, or ramming, allowing for faster installation and reduced downtime. Additionally, if any damage occurs, they can be easily repaired or patched. 6. Strong mechanical strength: Monolithic refractories possess sufficient mechanical strength to endure the stresses and pressures encountered during their service life. This guarantees their structural integrity, even under high load conditions. Overall, the versatile and reliable properties of monolithic refractories make them an excellent choice for a wide range of industrial applications that require resistance to high temperatures, chemicals, and thermal shock.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Performance Ladle Slide Gate for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords