Mullite Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Mullite Based Mortar for Hot Blast Stove

ALRE mullite based mortar for hot blast stove made as per international standards, is known for its low thermal conductivity, high refractoriness, and excellent thermal shock resistance.

Technical data of Mullite Based Mortar for Hot Blast Stove

Item | High Alumina Mortar | |

Al2O3(%)≥ | 70 | |

M.O.R. (MPa) ≥ | 110℃×24h | 4 |

1200℃×3h | — | |

1300℃×2h | 6 | |

1400℃×2h | — | |

1500℃×2h | — | |

Grain size(%) | 110℃×24h (≤) | 1 |

1200℃×3h (≥) | 50 | |

Refractoriness (℃) ≥ | 1790 | |

Refractoriness Under Load(℃) ≥ | 1550 | |

Adhesive Time(min) | 1-2 | |

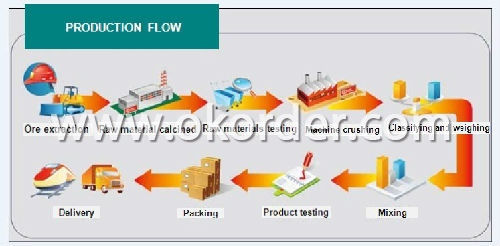

Production line and Packing of Mullite Based Mortar for Hot Blast Stove

Feature of Mullite Based Mortar for Hot Blast Stove

Excellent thermal shock resistance

Excellent mechanical strength

Low thermal conductivity

High refractoriness

Application of Mullite Based Mortar for Hot Blast Stove

ALRE tmullite based mortar for hot blast stove can be used widely for same material masonry.

Production Flow of Mullite Based Mortar for Hot Blast Stove

- Q:Can monolithic refractories be customized for specific iron and steel processing requirements?

- Yes, monolithic refractories can be customized for specific iron and steel processing requirements. Monolithic refractories are known for their versatility and ability to be tailored to various applications. The composition, physical properties, and installation techniques of monolithic refractories can be adjusted to meet the specific needs of iron and steel processing. For example, the choice of raw materials used in the manufacturing of monolithic refractories can be customized to withstand the high temperatures and harsh chemical environments encountered in iron and steel processing. Different types of aggregates, binders, and additives can be selected to enhance the refractory's resistance to thermal shock, erosion, and corrosion. Furthermore, the installation method of monolithic refractories can be adapted to suit the specific requirements of iron and steel processing. Whether it is gunning, casting, ramming, or spraying, the installation technique can be customized to ensure optimal performance and longevity in the given application. Additionally, monolithic refractories can also be tailored to specific shapes and sizes to fit the various equipment and structures used in iron and steel processing. This allows for a more precise and efficient lining of furnaces, ladles, tundishes, and other vessels, thereby improving the overall productivity and performance of the process. In summary, monolithic refractories can be customized to meet the specific iron and steel processing requirements by adjusting their composition, physical properties, installation techniques, and shape. This customization ensures that the refractories can withstand the extreme conditions encountered in these industries, leading to improved performance, longer service life, and enhanced productivity.

- Q:How do monolithic refractories perform in ladle lining applications in the iron and steel industry?

- Monolithic refractories are highly effective in ladle lining applications in the iron and steel industry. Their outstanding thermal shock resistance, erosion resistance, and high refractoriness allow them to withstand the extreme conditions of molten metal and slag in ladles. Monolithic refractories also offer excellent thermal conductivity and low porosity, ensuring efficient heat transfer and preventing slag infiltration. Additionally, their easy installation and maintenance make them a preferred choice for ladle lining, ensuring prolonged service life and enhanced productivity in the iron and steel industry.

- Q:How can the lifespan of monolithic refractories be extended?

- The lifespan of monolithic refractories can be extended through various measures, including proper installation, regular maintenance, and implementing effective operating practices. Firstly, it is crucial to ensure proper installation of monolithic refractories. This involves following the manufacturer's guidelines, using appropriate equipment and techniques, and ensuring correct curing and drying processes. When installed correctly, monolithic refractories are better equipped to withstand thermal stresses and chemical attacks, thereby prolonging their lifespan. Regular maintenance plays a key role in extending the lifespan of monolithic refractories. This includes routine inspections to identify any signs of wear, erosion, or cracking. Timely repairs or replacements should be carried out to prevent further damage. Additionally, applying protective coatings or sealants can help reduce erosion and chemical attacks, further enhancing the refractories' longevity. Implementing effective operating practices is another crucial aspect. Maintaining optimal operating conditions, such as controlling temperature fluctuations, can minimize thermal shocks and reduce the risk of spalling or cracking of the refractories. Proper material selection is also important, as using refractories that are specifically designed for the intended application can increase their resistance to chemical attacks and extend their lifespan. Furthermore, ensuring proper handling and storage of monolithic refractories is essential. They should be stored in a dry, clean environment, away from moisture and extreme temperatures, to prevent premature degradation. Handling should be done with care, avoiding excessive impact or rough treatment that could cause damage. Finally, it is beneficial to engage with experienced professionals or consult with refractory suppliers to gain valuable insights and guidance on best practices for extending the lifespan of monolithic refractories. Their expertise can help in making informed decisions regarding installation, maintenance, and operating practices, ultimately maximizing the refractories' lifespan and optimizing their performance.

- Q:What are monolithic refractories?

- Monolithic refractories are a type of heat-resistant materials used to line high-temperature industrial equipment such as furnaces, kilns, and reactors. Unlike traditional refractories, which are made of pre-formed bricks or shapes, monolithic refractories are a single, solid piece that can be easily shaped and installed. They are composed of various aggregates, binders, and additives, providing excellent thermal insulation and resistance to extreme temperatures, chemical attacks, and mechanical stress. Monolithic refractories offer flexibility, cost-effectiveness, and improved installation efficiency compared to traditional brick refractories.

- Q:How do monolithic refractories contribute to the overall efficiency of ladle slagging operations?

- Monolithic refractories play a crucial role in improving the overall efficiency of ladle slagging operations. Ladle slagging is a process that involves the removal of impurities from molten metal in a ladle before it is poured into molds or further processed. One of the key contributions of monolithic refractories is their ability to withstand high temperatures, which is essential in ladle slagging operations. The refractory lining of the ladle needs to be able to endure the extreme heat generated by the molten metal and slag, as well as the chemical reactions occurring during the process. Monolithic refractories, with their high thermal stability, prevent the lining from cracking or deteriorating, thus ensuring the integrity of the ladle and maintaining its efficiency. Additionally, monolithic refractories offer excellent resistance to chemical erosion and corrosion. During the ladle slagging process, the molten metal and slag can contain various impurities and aggressive chemicals, such as sulfur, phosphorus, and other oxides. These substances can attack and degrade the lining of the ladle, compromising its efficiency. However, monolithic refractories are designed to resist these chemical attacks, thereby extending the lifespan of the ladle and reducing the need for frequent repairs or replacements. Moreover, monolithic refractories provide good thermal insulation properties. Ladle slagging operations require precise temperature control to ensure the desired chemical reactions and efficient removal of impurities. The thermal insulation offered by monolithic refractories helps to maintain a consistent temperature within the ladle, preventing heat loss and allowing for optimized slagging conditions. This insulation also minimizes energy consumption and improves the overall energy efficiency of the ladle slagging process. In conclusion, monolithic refractories contribute significantly to the overall efficiency of ladle slagging operations. Their ability to withstand high temperatures, resist chemical erosion, and provide thermal insulation ensures the integrity and longevity of the ladle. By reducing the need for frequent repairs and allowing for precise temperature control, monolithic refractories optimize the slagging process, leading to improved productivity and cost-effectiveness.

- Q:What are the typical applications of monolithic refractories in blast furnaces?

- Monolithic refractories are widely used in blast furnaces due to their unique properties and applications. These refractories are composed of a single, homogeneous material that can be shaped and installed in various forms without the need for joints or seams. This characteristic makes them ideal for lining and protecting the different zones of a blast furnace. One typical application of monolithic refractories in blast furnaces is the lining of the hearth. The hearth is the bottom part of the furnace where molten iron and slag accumulate. Monolithic refractories are used to create a durable and heat-resistant lining that can withstand the extreme temperatures and chemical reactions occurring in this area. Another common application is the lining of the bosh, which is the transition zone between the hearth and the stack of the blast furnace. The bosh is subjected to high temperatures and mechanical stresses due to the movement of the burden materials. Monolithic refractories with high thermal shock resistance and abrasion resistance are used to ensure the longevity and efficiency of the bosh. Monolithic refractories are also used for the lining of the stack and the tuyere area. The stack is the vertical part of the furnace where the reduction of iron ore takes place. The tuyere area is where the hot blast of air is injected into the furnace. Both of these areas require refractories that can withstand high temperatures, chemical reactions, and mechanical stresses. Furthermore, monolithic refractories are used for repairs and maintenance in blast furnaces. Due to the harsh conditions inside the furnace, the lining may deteriorate over time. Monolithic refractories can be easily applied as patching materials to restore the integrity of the lining and extend the furnace's lifespan. In summary, the typical applications of monolithic refractories in blast furnaces include lining the hearth, bosh, stack, and tuyere area, as well as for repairs and maintenance. These refractories provide excellent thermal shock resistance, abrasion resistance, and durability, making them essential for the efficient operation of blast furnaces in the iron and steel industry.

- Q:What are the common manufacturing processes used for monolithic refractories?

- The common manufacturing processes used for monolithic refractories include: 1. Mixing: The first step in the manufacturing process is the proper mixing of the raw materials. This involves carefully measuring and combining the different ingredients to ensure a homogeneous mixture. 2. Wetting: Once the ingredients are mixed, water or a liquid binder is added to wet the mixture. This helps in improving the workability and plasticity of the material, making it easier to shape and mold. 3. Forming: The wet mixture is then shaped into the desired form using various techniques such as casting, gunning, ramming, or extrusion. Casting involves pouring the wet mixture into a mold and allowing it to solidify, while gunning uses a spray gun to apply the material onto a surface. Ramming involves compacting the wet mixture into a mold using a ramming tool, and extrusion involves forcing the wet mixture through a die to create specific shapes. 4. Drying: After forming, the shaped monolithic refractory is dried to remove any excess moisture. This is typically done in a controlled environment with specific temperature and humidity conditions to prevent cracking or warping. 5. Firing: Once dried, the monolithic refractory is fired at high temperatures to achieve its desired properties. This process, known as sintering, helps in bonding the particles together and increasing the strength and stability of the material. 6. Finishing: After firing, the monolithic refractory may undergo additional finishing processes such as grinding, polishing, or coating to improve its surface quality and enhance its performance. These common manufacturing processes ensure the production of high-quality monolithic refractories with consistent properties and performance characteristics.

- Q:How do monolithic refractories withstand the alkali attacks in cement kiln applications?

- Due to their unique composition and structure, monolithic refractories are capable of withstanding alkali attacks in cement kiln applications. Unlike traditional brick refractories, these refractories are made from a single material, resulting in a more uniform and dense structure. When exposed to alkali attacks in cement kilns, monolithic refractories create a barrier against the corrosive alkali substances by forming a protective layer on the surface. This protective layer is formed through reactions between the alkali substances and the refractory material, leading to the development of a stable compound that resists further attacks. Additionally, monolithic refractories possess high chemical resistance, allowing them to endure the aggressive conditions inside cement kilns. Their low porosity design minimizes the infiltration of alkali substances into the refractory material, reducing the risk of alkali attacks and extending the lifespan of the refractory lining. Furthermore, monolithic refractories are frequently manufactured using materials with elevated melting points, such as alumina, silica, and magnesia. These materials exhibit exceptional thermal stability, enabling the refractories to withstand the high temperatures in cement kilns without significant deterioration. This thermal stability is crucial in preventing the formation of cracks and spalling, which could permit alkali penetration and subsequent harm to the refractory lining. In conclusion, monolithic refractories are specifically engineered to resist alkali attacks in cement kiln applications by forming a protective layer, possessing high chemical resistance, and demonstrating excellent thermal stability. These characteristics make them an ideal choice for lining cement kilns, ensuring long-term performance and durability.

- Q:How do monolithic refractories prevent thermal shock in the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories to prevent thermal shock. These refractories offer exceptional thermal insulation and resistance to extreme temperatures, playing a vital role in maintaining the integrity of the refractory lining. Thermal shock occurs when there is a sudden and significant change in temperature, leading to stress and cracks in the refractory lining. Given the extremely high temperatures that can be reached in the iron and steel industry, the risk of thermal shock is particularly pronounced. To combat this, monolithic refractories possess a low thermal conductivity, enabling them to effectively insulate against rapid temperature fluctuations. This insulation property allows them to endure the extreme temperatures involved in the iron and steel production process without compromising their structural integrity. Moreover, monolithic refractories are specifically engineered to exhibit high thermal shock resistance. This means they can effectively absorb and distribute the thermal stresses caused by temperature variations, thereby minimizing the likelihood of cracking or spalling. Aside from their exceptional thermal insulation and shock resistance, monolithic refractories also demonstrate outstanding corrosion and erosion resistance. This is especially important in the corrosive environment of the iron and steel industry, where molten metals, slag, and gases are present. By providing a dependable and long-lasting lining in furnaces, ladles, and other equipment utilized in the iron and steel industry, monolithic refractories ensure that thermal shock is mitigated. Consequently, this helps to maintain the efficiency and productivity of the production process while extending the lifespan of the equipment.

- Q:How do monolithic refractories help in improving the quality of iron and steel products?

- Several ways exist in which monolithic refractories play a crucial role in enhancing the quality of iron and steel products. Firstly, these refractories are utilized for lining furnaces and other high-temperature equipment in the iron and steel industry. By offering excellent thermal insulation, monolithic refractories aid in maintaining a consistent and controlled temperature inside the furnace, thus ensuring efficient heating and melting of metals. Furthermore, the utilization of monolithic refractories aids in reducing heat loss, thereby enhancing the energy efficiency of the process. This not only leads to cost savings but also minimizes the environmental impact associated with high energy consumption. Additionally, the insulation properties of monolithic refractories contribute to the reduction of thermal stresses within the furnace, preventing cracks and other structural damages that could potentially affect the quality of the iron and steel products. Moreover, monolithic refractories possess exceptional resistance to chemical reactions, corrosion, and erosion caused by molten metals, slag, and other harsh substances. This resistance helps in maintaining the integrity of the refractory lining, preventing the contamination of iron and steel products by unwanted impurities. As a result, the quality of the final products, such as steel bars, sheets, or pipes, is enhanced, meeting the desired specifications and industry standards. Another advantage offered by monolithic refractories is their ability to provide a sleek and pristine lining surface. This smoothness minimizes the adherence of slag, molten metal, and other by-products, thereby reducing the risk of defects and ensuring a higher-quality finish for the iron and steel products. Additionally, the clean lining surface facilitates easy maintenance and cleaning, enabling efficient and effective operations. In conclusion, monolithic refractories significantly contribute to the improvement of iron and steel product quality through their exceptional thermal insulation, resistance to chemical reactions, erosion, and corrosion, as well as their ability to provide a sleek and pristine lining surface. By ensuring consistent temperatures, reducing heat loss, preventing structural damages, and maintaining a clean environment, monolithic refractories enhance the overall efficiency and integrity of the iron and steel production process, resulting in high-quality end products.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Mullite Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords