High Density Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

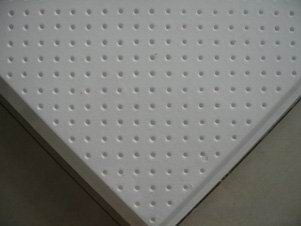

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

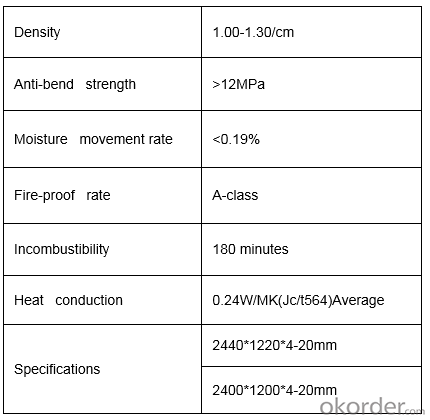

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:How do I distinguish between calcium silicate boards and asbestos? I heard some people use cement board instead of calcium silicate board, containing asbestos ingredients!

- Asbestos is a natural fibrous siliceous mineral of the generic term, is widely used in building materials fire board silicate mineral fiber, is also the only natural mineral fiber, it has good tensile strength and good heat insulation (Asbestos), asbestos (brown asbestos) and crocidolite (blue asbestos), of which the content of chrysotile asbestos (asbestos), asbestos (asbestos) The most abundant, the most widely used.

- Q:What are the well-known brands of calcium silicate boards in China?

- At present, there are about 50 production lines of calcium silicate board in China, mainly distributed in Guangdong, Hebei, Zhejiang, Jiangsu, Jiangxi and other places, Guangdong currently has more than 10 calcium silicate board production enterprises, and each year are also more than 30% increase.

- Q:FC and calcium silicate board which is good

- FC board and calcium silicate board process is different from the use of the same, the price is basically the same. Each board to see where the use of performance which board, including the density, technical indicators are different, there is a big difference.

- Q:Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong Ding set. Design no requirements, the nail spacing of 1000mm.

- Q:Two layers of calcium silicate board in the middle of what kind of sound insulation board

- It is too thick. The effect is relatively popular fire damping sound insulation board is not a level.

- Q:Integrated ceiling and calcium silicate board which is good

- Calcium silicate board ceiling in addition to not in the kitchen outside the bathroom can be ... ... High strength, small thermal conductivity, high temperature, corrosion resistance Widely used in industrial and commercial construction of ceiling ceilings and partitions Because the fear of soot is not easy to clean up ... ... so different places to use a different ceiling

- Q:Why is silicon calcium board not suitable for use in home decoration?

- This is from the decoration style, the material is not appropriate, silicon calcium gypsum board to semi-water gypsum and silicone oil as the main material, the surface of the silicone oil with the transport installation will be out of friction, a long time will be depleted Loss, if you run JS, silicone oil coating is not full, then the moisture effect is even worse, over time the moisture, deformation, mold, yellow is sure

- Q:Calcium silicate board production line

- Flow slurry method is equipped with a stirrer and separator in the headbox. When the slurry reaches a certain level in the headbox, it flows naturally through the horizontal cloth pulp plate and the inclined flow slurry plate to the blanket to form the initial material layer, The initial material layer through a number of vacuum box forced dehydration, winding to the forming tube I, to achieve the required thickness from the molding tube after pulling the wet blank, the next process into a variety of products.

- Q:Calcium silicate board and magnesium silicate board which is better

- In recent years, with the improvement of production technology, the use of calcium silicate board is also more and more common in Guangdong, in addition to the external brand of Etterit, there are Oulang, Jinfu, Chun Figure, Yin Xing and other own Brand.

- Q:What is the thermal conductivity of calcium silicate board?

- Calcium silicate board is mainly used for: ceiling / inside (outside) partition or waterproof moisture requirements area Has a good fire, moisture, insulation effect, the thermal conductivity than the solid wood floor!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords