Heavy Duty Prop 1.6M-2.7M HDG Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

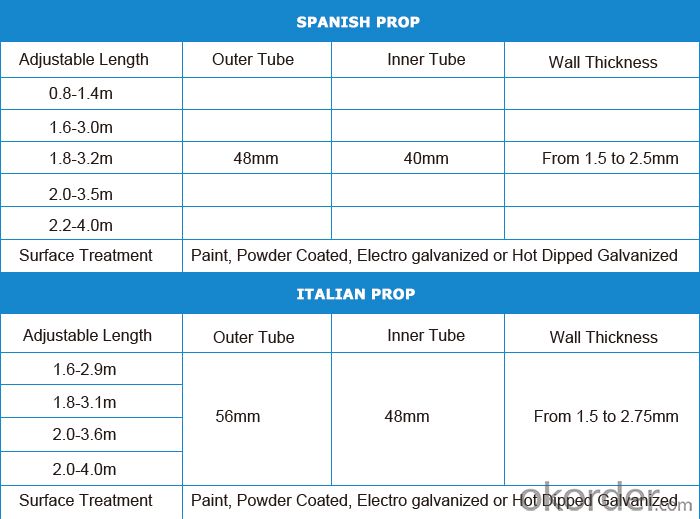

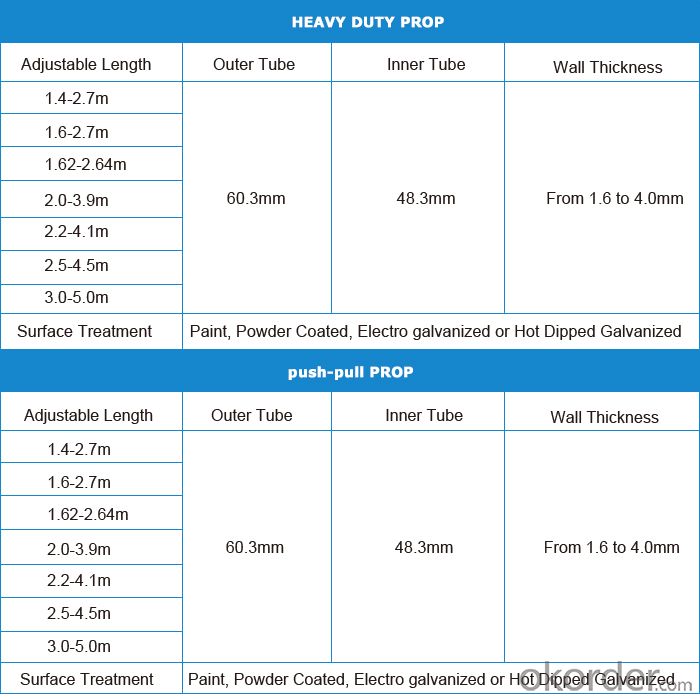

Quick Details of Heavy Duty Prop 1.6M-2.7M HDG Q235 Steel Prop Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Heavy Duty Prop 1.6M-2.7M HDG Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Compared to Pankou scaffolding and scaffolding have what distinction, what are the advantages

- Pankou scaffolding and scaffolding to build shape is not the same, is not the same, the price is not the same1, Pankou scaffolding hot-dip galvanizing process, lasting up to 15 years of age or above.2, scaffolding, low cost, high efficiency, convenient disassembly and effort to build.

- Q:Cantilever beam type scaffolding can not exceed the maximum number of not married

- Cantilever scaffold cantilever beam fixed method is as follows:1, the floor in the rebar at the same time, the embedded two door shaped clamp, each clamping hoop is composed of 2 14mm grade steel made a root diameter, the first door shaped clamp from the wall 450mm, second door shaped clamp from the other end of the 350mm, the door shaped card hook stirrup slab reinforcement, to meet the requirements of the anchorage the cantilever beam, door shaped clamp is inserted in the middle, but also with a fixed electric welding.

- Q:I know the ivy sort of glues itself to whatever surface with little sticky pads so that will take care of itself on the back of my house but can I use the existing Ivy for the wisteria to grab onto and climb up or will the wisteria be too heavy and pull the ivy down? I'd rather avoid having to build something for the wisteria to wrap itself around. Any suggestions? Thanks! : )

- The wisteria will climb on anything and everything it can get it's tendrils on. But are you sure you want it on your ivy? Wisteria is the most aggressive grower,and will overtake the ivy, choking it out. As a matter of fact it's not the kind of plant to have close to your house. I know,the blooms are pretty and all but the rest of the plant is a holy terror on your siding,shingles,etc. If you still want to plant it near your house, choose a spot well clear of the power lines that supply your electricity.

- Q:Where can I source scaffolding steel/aluminium planks with rubber end caps?I am having much difficultly finding anything, can you assist?Thank you in advance.

- Maybe something like a window washers scafolding planks...?

- Q:hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- leave the dry blood let it heal be patient

- Q:Also what 2 cell populations in the body that don't routinely undergo cell division

- The first one is vague. The answer could be the mitotic spindle. It might be kinetochore microtubules. It might be talking about the kinetchores on the chromosomes instead of the microtubules that attach to the kinetochores. It could possibly even be talking about the centromeres, though to me that seems less likely. Neurons in the adult brain (and mature muscle cells?) do not routinely undergo cell division.

- Q:Scaffolding Vertical Standard, Length: 3000mm, Part Number AS1001

- Please okorder Type ‘Aluminum Scaffolding+supplier+your location’ into its ‘Search’ panel, and click on ‘Enter’. Several pages of site listings giving details and links of suppliers who offer Aluminum Scaffoldings in, or near, your locality will be presented to you. Contact them, one by one, and then choose the supplier who suits your specific needs best. Happy hunting !

- Q:Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q:How to set up the temporary structure of the external structure of the balcony on the two structure

- Earthwork:The pile cap is shallow, the foundation beam and sand filling quantity is less, the depth is to the outdoor floor 1.5m, so the earthwork construction adopts the mechanical leveling site construction scheme. Backfill soil must be layered compaction, density of not less than 0.9. Construction lap should be compact, interval time should not be too long, in case of rain water, the construction of various types of pipe should be synchronized with the foundation construction.

- Q:I had my scaffold pierced yesterday and now it is swollen and red. Its throbbing and painful. I have cleaned it and applied ice and antiseptic spray.I don't own any sea salt.HELP ME! I'M SO TEMPTED TO REMOVE IT.

- Antiseptics are too harsh for a healing piercing, the pain, swelling and redness is completely normal. Stop using antiseptic and go to the grocery store to get some non-iodized sea salt, its only a few dollars and you can find it in the spice aisle where the regular salt is.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Duty Prop 1.6M-2.7M HDG Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords