HDPE Plastic Geocell / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

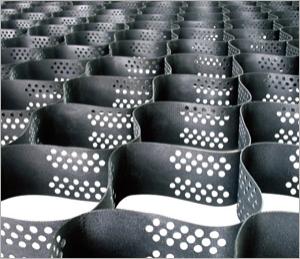

Description Of HDPE Plastic Geocell

Geocell is honeycomb shaped structures using material of HDPE or PP, welded by high frequency ultrasonic.

Main Features of HDPE Plastic Geocell

Geocell Cellular Confinement Systems / Geocell / Geocell systems / HDPE Smooth/Textured Plastic Geocell

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specifications of HDPE Plastic Geocell

1.Height:50mm-200mm

2.Welding distance:330mm-1000mm

3.Thickness of sheet: 1.0mm-1.5mm

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Applications of HDPE Plastic Geocell

To stable the roadbed of highway/railway.

To bear the load of dyke, retaining wall.

To improve the watercourse of shallow river.

To support the pipeline and sewer.

To be used as independent wall, wharf and breakwater, etc..

To be used for the regulation of the desert, beaches, river bed and river bank.

IMages of HDPE Plastic Geocell

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q:Are geocells resistant to abrasion?

- Yes, geocells are generally resistant to abrasion due to their durable and high-strength materials, such as HDPE (high-density polyethylene). These materials are designed to withstand various environmental conditions, including abrasion caused by heavy traffic or external forces.

- Q:Can geocells be used in pipeline trench backfilling?

- Yes, geocells can be used in pipeline trench backfilling. Geocells are a type of geosynthetic material that can be filled with soil or other granular material to create a stable and reinforced support system. By placing geocells in the trench and filling them with backfill material, the geocells provide confinement and prevent lateral movement of the soil, improving the load-bearing capacity of the backfill. This can help prevent settlement, soil erosion, and potential damage to the pipeline.

- Q:Are geocells suitable for use in oil and gas pipeline construction?

- Yes, geocells are suitable for use in oil and gas pipeline construction. Geocells provide significant benefits such as increased load-bearing capacity, improved soil stability, and enhanced erosion control. They can effectively reinforce the ground and prevent soil movement, which is crucial in pipeline construction to ensure the integrity and longevity of the infrastructure. Additionally, geocells are easy to install and can reduce project costs and construction time.

- Q:How do geocells improve the performance of paved roads?

- Geocells improve the performance of paved roads by providing a stable and reinforced base. These cellular confinement systems are filled with compacted soil or aggregate, creating a strong and rigid structure that enhances load-bearing capacity and distributes the load more evenly. As a result, geocells prevent lateral spreading of the base materials, reduce rutting, and increase the overall durability and longevity of the road.

- Q:How do geocells improve the performance of asphalt pavements?

- Geocells improve the performance of asphalt pavements by providing a stable base reinforcement and confinement, which enhances the load-bearing capacity, reduces deformation, and prevents lateral spreading of the base materials. This leads to increased pavement longevity, reduced maintenance costs, and improved overall performance under heavy traffic loads.

- Q:Can geocells be used in wastewater treatment?

- Yes, geocells can be used in wastewater treatment. They can be utilized in constructing containment structures, such as wastewater lagoons or treatment ponds, to provide stability, prevent erosion, and improve the overall efficiency of the treatment process. Geocells can help in reducing the risk of leakage and contamination, as well as enhancing the structural integrity of the treatment system.

- Q:What types of infill materials can be used with geocells?

- Various types of infill materials can be used with geocells, including but not limited to soil, sand, gravel, crushed rock, recycled materials, and even concrete. The choice of infill material depends on the specific application, desired load-bearing capacity, and environmental conditions.

- Q:How are geocells used in erosion control?

- Geocells are used in erosion control by providing a stable and strong structure to reinforce soil and prevent erosion. They are typically filled with soil or aggregate material and placed on slopes or areas prone to erosion. The interconnected cells within the geocell system allow for proper drainage while reducing water flow velocity, thus minimizing soil erosion.

- Q:Are geocells suitable for use in sports field construction?

- Yes, geocells are suitable for use in sports field construction. Geocells provide a stable base for the turf, prevent soil erosion, and improve drainage. They also enhance the load-bearing capacity of the field, making it suitable for heavy sports activities.

- Q:What is the maximum compressive strength of geocells?

- The maximum compressive strength of geocells can vary depending on the specific product and its design. However, typical geocells have a compressive strength ranging from 200 kPa (kilopascals) to 800 kPa or more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Plastic Geocell / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords