All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can geocells be used for erosion control in beach restoration projects?

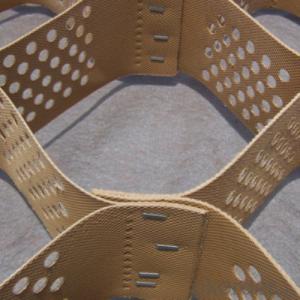

Yes, geocells can be used for erosion control in beach restoration projects. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene that can be filled with soil or other suitable materials. They provide a stable foundation and prevent erosion by confining the fill material and reinforcing the beach area. Geocells also help to reduce wave impact and promote vegetation growth, making them an effective solution for erosion control in beach restoration projects.

Can geocells be used in construction of erosion control structures for parks and recreational areas?

Yes, geocells can be effectively used in the construction of erosion control structures for parks and recreational areas. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) that are filled with soil or aggregate materials. They provide excellent erosion control and stabilization by preventing soil erosion, promoting vegetation growth, and enhancing water drainage. Geocells can be used to create retaining walls, slope protection, and channel linings, making them suitable for various erosion control applications in parks and recreational areas.

Are geocells suitable for use in tree root protection systems?

Yes, geocells are suitable for use in tree root protection systems. Geocells provide a stable and permeable surface that allows for proper root growth and development while protecting the soil from erosion. They also distribute the load evenly, preventing soil compaction and damage to the tree roots.

Are geocells suitable for helipad construction?

Yes, geocells are suitable for helipad construction. Geocells provide a stable and durable foundation for helipads, offering excellent load-bearing capacity and erosion control. They are easy to install, cost-effective, and can withstand heavy aircraft traffic, making them an ideal choice for helipad construction projects.

What is the installation process for geocells?

The installation process for geocells typically involves the following steps:

1. Site preparation: The area where the geocells will be installed needs to be cleared of any debris, vegetation, or rocks. The site should be graded to ensure a level surface.

2. Base stabilization: Depending on the condition of the soil, a geotextile or geogrid may be laid down to improve the load-bearing capacity of the base. This helps to prevent the geocells from sinking into the soil.

3. Geocell placement: The geocells are laid out on the prepared base, starting from one end and working towards the other. Each geocell is connected to the adjacent one using interlocking tabs or connectors.

4. Filling the cells: Once the geocells are in place, they are filled with a suitable infill material such as gravel, sand, or soil. This material should be compacted to ensure proper stability and load distribution.

5. Compaction and finishing: After the cells are filled, the infill material is compacted using vibratory rollers or other compaction equipment. This helps to further stabilize the geocells and ensure a level surface.

6. Surface protection: If necessary, a geotextile or erosion control fabric may be placed on top of the filled geocells to provide additional protection against erosion and vegetation growth.

Overall, the installation process for geocells involves site preparation, base stabilization, geocell placement, filling the cells, compaction, and surface protection. It is important to follow the manufacturer's guidelines and consult with a professional engineer to ensure proper installation and maximize the performance of geocells.

Wholesale Geocells from supplier in Indonesia

Our team of experts is dedicated to providing you with top-notch service, from the initial sales process to ongoing technical support. We understand the unique challenges of the Indonesian market and can offer customized solutions to meet your specific needs.

Our Geocell products are designed to provide effective soil stabilization, erosion control, and slope protection. Whether you are working on a road construction project, building infrastructure, or developing a landfill, our Geocells can help ensure the stability and longevity of your project.

At CNBM, we pride ourselves on our commitment to quality and innovation. Our Geocells are manufactured using high-quality materials and advanced technology, ensuring durability and performance. With our extensive product range, we can provide you with the right Geocell solution for your project.

Additionally, as a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and efficient procurement processes, making your experience with us seamless and hassle-free.

We invite you to experience our comprehensive Geocells solutions in Indonesia. Contact us today for sales inquiries, quotations, and technical support. Let us help you achieve success in your projects with our reliable and efficient Geocell products.

Our Geocell products are designed to provide effective soil stabilization, erosion control, and slope protection. Whether you are working on a road construction project, building infrastructure, or developing a landfill, our Geocells can help ensure the stability and longevity of your project.

At CNBM, we pride ourselves on our commitment to quality and innovation. Our Geocells are manufactured using high-quality materials and advanced technology, ensuring durability and performance. With our extensive product range, we can provide you with the right Geocell solution for your project.

Additionally, as a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and efficient procurement processes, making your experience with us seamless and hassle-free.

We invite you to experience our comprehensive Geocells solutions in Indonesia. Contact us today for sales inquiries, quotations, and technical support. Let us help you achieve success in your projects with our reliable and efficient Geocell products.