All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different corrosion testing requirements for seamless steel pipe?

The different corrosion testing requirements for seamless steel pipe typically include tests such as salt spray test, immersion test, electrochemical corrosion test, and corrosion resistance evaluation. These tests aim to assess the pipe's resistance to various corrosive environments and provide information on its performance and durability.

How is seamless steel pipe used in the aerospace industry?

Seamless steel pipe is extensively used in the aerospace industry for various applications. It is utilized in the construction of aircraft engines, fuel systems, hydraulic systems, and structural components. The seamless nature of the pipe ensures a high level of reliability and strength, making it suitable for withstanding the extreme conditions experienced during flight. Additionally, seamless steel pipes are known for their resistance to corrosion and high-pressure environments, making them ideal for aerospace applications where safety and performance are paramount.

Can seamless steel pipes be used for food and beverage manufacturing?

Yes, seamless steel pipes can be used for food and beverage manufacturing. These pipes are often made from stainless steel, which is resistant to corrosion and does not react with food or beverages. Additionally, seamless steel pipes provide a smooth inner surface, preventing the accumulation of bacteria and ensuring the hygiene and safety of the products being transported.

How are seamless steel pipes transported and stored?

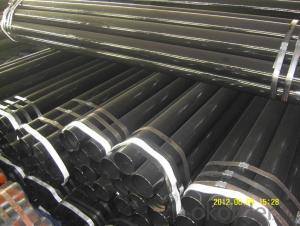

Seamless steel pipes are typically transported and stored in a carefully organized manner to ensure their quality and prevent any damage. They are usually transported in bundles or by stacking them on flatbed trucks, ships, or trains. During transportation, proper securing mechanisms such as straps or chains are used to prevent any movement or shifting.

When it comes to storage, seamless steel pipes are stored in warehouses or yards with adequate space and facilities to protect them from environmental factors. They are usually stacked in a way that minimizes contact with the ground and prevents any deformation or corrosion. Additionally, protective measures such as covering them with a tarp or plastic wrap may be used to safeguard against dust, moisture, and other potential contaminants.

Overall, the transportation and storage processes for seamless steel pipes are carefully managed to ensure their integrity and readiness for use in various industries.

Wholesale Seamless Steel Pipe from supplier in Indonesia

Whether you are in need of Seamless Steel Pipe for construction, oil and gas, or any other industry, we have the capabilities to meet your specific requirements. Our extensive product range includes various sizes, grades, and specifications to ensure that we can provide the right solution for your project.

In addition to our wide product selection, we also offer value-added services such as cutting, threading, and coating to further customize the Seamless Steel Pipe according to your needs. Our dedicated team of experts will work closely with you to understand your project requirements and recommend the most suitable products and services.

As a subsidiary of CNBM, we adhere to international quality standards and ensure that all our products undergo rigorous testing to guarantee their performance and durability. We also have a strong focus on sustainability and strive to minimize our environmental impact through responsible manufacturing practices.

At every step of the procurement process, from initial inquiry to delivery, we prioritize customer satisfaction. Our team is committed to providing prompt and reliable service, ensuring that your Seamless Steel Pipe is delivered on time and in perfect condition.

Choose us as your Seamless Steel Pipe supplier in Indonesia and experience the convenience, reliability, and quality that we offer. Contact us today to discuss your requirements and let us assist you in finding the best solution for your project.

In addition to our wide product selection, we also offer value-added services such as cutting, threading, and coating to further customize the Seamless Steel Pipe according to your needs. Our dedicated team of experts will work closely with you to understand your project requirements and recommend the most suitable products and services.

As a subsidiary of CNBM, we adhere to international quality standards and ensure that all our products undergo rigorous testing to guarantee their performance and durability. We also have a strong focus on sustainability and strive to minimize our environmental impact through responsible manufacturing practices.

At every step of the procurement process, from initial inquiry to delivery, we prioritize customer satisfaction. Our team is committed to providing prompt and reliable service, ensuring that your Seamless Steel Pipe is delivered on time and in perfect condition.

Choose us as your Seamless Steel Pipe supplier in Indonesia and experience the convenience, reliability, and quality that we offer. Contact us today to discuss your requirements and let us assist you in finding the best solution for your project.