Gritted Frp Grating-1/12 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

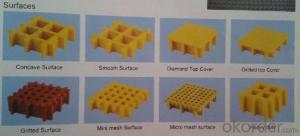

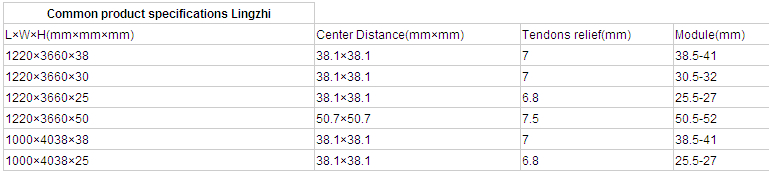

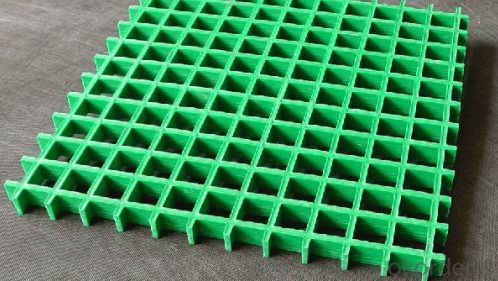

fiberglass mesh grating

1.meet ASTM E-84 AND ISO9001

2.anti-corrosion floor

3.anti-conductive

4.walkway,platform,trench cove

fiberglass mesh grating

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

Panel Size:

- Q:What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles are exceptional. Factors such as fiber type, arrangement, resin properties, and profile design determine their load-bearing capacity. Due to their high strength-to-weight ratio, FRP pultrusion profiles are widely used in various industries. The reinforcing fibers, made of materials like fiberglass or carbon fiber, provide the profiles with outstanding tensile and flexural strength. These fibers are embedded in a resin matrix, further enhancing the profiles' load-bearing capabilities. Manufacturers can customize the load-bearing capacity of FRP pultrusion profiles by adjusting fiber type, orientation, and resin properties. This flexibility allows for a wide range of design options, enabling engineers to optimize the profiles for different applications. Additionally, FRP pultrusion profiles have excellent corrosion resistance, making them suitable for harsh environments. Unlike steel or wood, they do not rust or rot, ensuring long-lasting durability and structural integrity. In conclusion, FRP pultrusion profiles have impressive load-bearing capabilities, making them a reliable choice for a variety of applications, including structural supports, bridges, platforms, and industrial equipment.

- Q:Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q:Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q:Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength and durability. They are generally resistant to impact from flying debris due to their inherent properties. The combination of the reinforcing fibers, typically made of fiberglass, and the polymer matrix provides excellent impact resistance. The specific resistance to impact from flying debris can vary depending on the specific design, thickness, and composition of the FRP pultrusion profiles. However, in most cases, these profiles are designed to withstand impact forces and can effectively resist damage caused by flying debris. Furthermore, FRP pultrusion profiles are often used in applications where impact resistance is crucial, such as in construction, transportation, and infrastructure industries. These profiles have been tested and proven to withstand various impact scenarios, making them a reliable choice for applications where flying debris is a concern. It is important to note that while FRP pultrusion profiles offer good impact resistance, the severity of the impact and the velocity of the flying debris can still affect the level of damage. Therefore, it is advisable to consult with the manufacturer or engineer to ensure the specific FRP profile chosen is suitable for the intended application and potential impact conditions.

- Q:Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to humidity and moisture. The combination of fiberglass reinforcement and a polymer resin matrix makes them inherently resistant to water absorption. Unlike traditional materials like wood or metal, FRP pultrusion profiles do not swell, warp, or corrode when exposed to moisture or high humidity levels. This resistance to moisture makes FRP pultrusions suitable for a wide range of applications in various industries, including construction, infrastructure, and marine environments. Additionally, FRP pultrusion profiles can be further enhanced with additional protective coatings or surface finishes to provide even greater resistance to moisture and humidity.

- Q:Can FRP pultrusion profiles be used in water treatment plants?

- Indeed, water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. The utilization of FRP pultrusion profiles in this industry brings forth numerous advantages that render them highly suitable. To begin with, FRP pultrusion profiles possess exceptional resistance to corrosion. Given the aggressive environments found in water treatment plants, where exposure to chemicals and moisture is common, the traditional materials like steel are prone to corrosion and degradation. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Moreover, FRP pultrusion profiles exhibit remarkable strength-to-weight ratios. This implies that they offer superior structural integrity while being lightweight, rendering them easier to handle and install within water treatment plants. Additionally, their high strength enables them to endure the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are non-conductive of electricity. This feature is particularly advantageous within water treatment plants where there may be a necessity to isolate electrical equipment or components to prevent short circuits and safeguard personnel. FRP profiles provide a safe and dependable solution in such cases. Lastly, FRP pultrusion profiles possess a long service life and necessitate minimal maintenance. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. All in all, due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life, FRP pultrusion profiles are an exceptional option for utilization in water treatment plants. Their usage can contribute to enhanced efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q:Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in oil refineries. The combination of their fiberglass reinforcement and resin matrix makes them impervious to many corrosive substances, ensuring long-term durability and performance in such harsh environments.

- Q:Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of safety barriers. FRP pultrusion profiles offer several advantages over traditional materials like steel or concrete when it comes to safety barrier applications. Firstly, FRP pultrusion profiles are incredibly strong and durable. They have high tensile strength, which means they can withstand heavy loads and impacts without deforming or breaking. This makes them suitable for withstanding the forces that safety barriers may encounter, such as vehicular collisions or other accidents. Secondly, FRP pultrusion profiles are lightweight. Compared to steel or concrete, FRP is significantly lighter, making it easier to transport, install, and handle during construction. The lightweight nature of FRP also reduces the overall weight of the safety barrier structure, which can be an advantage in terms of ease of installation and cost-effectiveness. Additionally, FRP pultrusion profiles have excellent corrosion resistance. Unlike steel, FRP is not susceptible to rust or corrosion, which can compromise the integrity and safety of the barrier over time. This makes FRP an ideal material for safety barriers that are exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which can be advantageous in certain safety barrier applications. For example, in areas where electrical or magnetic interference is a concern, such as near power lines or sensitive equipment, FRP barriers can provide an extra layer of safety by avoiding any potential electrical or magnetic hazards. Overall, FRP pultrusion profiles offer a reliable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties make them a suitable choice for a wide range of safety barrier applications.

- Q:Are FRP pultrusion profiles resistant to rotting or decaying?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to rotting or decaying. This is because FRP is composed of a combination of fiber reinforcement, such as fiberglass, and a polymer resin matrix. Unlike traditional materials like wood, which are susceptible to rot and decay when exposed to moisture and environmental elements, FRP pultrusion profiles are non-porous and do not absorb water. Additionally, the polymer resin used in FRP is highly resistant to chemical corrosion, making it unaffected by rot-causing agents such as fungi or bacteria. As a result, FRP pultrusion profiles have a significantly longer lifespan and require minimal maintenance compared to traditional materials, making them an excellent choice for applications where resistance to rotting or decaying is essential.

- Q:Can FRP pultrusion profiles be used in pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in pedestrian bridges. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for pedestrian bridge applications. These profiles can be customized to meet specific design requirements, ensuring the safe and efficient construction of pedestrian bridges.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gritted Frp Grating-1/12 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords