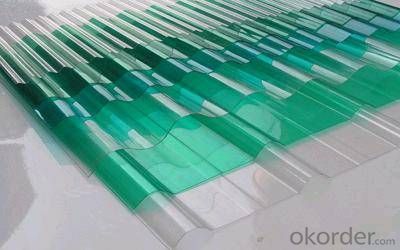

FIBER REINFORCE PLASTIC Transparancy Skylight Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FRP Skylight Panel:

1,Energy-saving

2,Heat-resistant material

3,Insulated against noise

4,Good quality

Features:

1) Owing to adopting continuous forming machinery, the length of theproducts is

not limited by product technique (except for transport equipment), any lengthand any section of panel can be made.

2) Excellent weather resistant property: surface is coated with ageingresistant film, which almost filters all UV light, the service life can be aslong as 20 years, greatly reduces the material cost and construction costbrought about by factors like the frequent change of PC boards

3) Good impact resistance and flexural strength make sure the translucentpanel can resist against the hit of hail and heavy typhoon

4) Excellent thermal stability: fiberglass panel belong to thermosettingfiber glass reinforced plastics, the thermal expansion coefficient is 2.2 x 10- 5cm/cmoc; PC (polycarbonate) are thermoplastics, the thermal expansion coefficientis 6.8 x 10 - 5cm/cmoc. When applied in big span buildings, the relativedisplacement of PC panel are too big, which results in the cracking andbreakage of hole position of screws, water leakage is virtually unavoidable

5) Fiberglass translucent panel are designed more personalized: FRP isheterogeneous material which can transform the direct light into diffusedlight, make the bright sunshine soft light friendly to man's eyes. The diffusedlight creates a comfortable working space (better effect in the region

6)General panels like PC, create direct light , which make the brightnessin the room uneven and cause man's eyes fatigued, overfocus makes floor orobjects change colors.

Heatnsulating property. The K (heat transfer coefficient) is small as2.0W/m2K. According to the test report issued by National Center forQuality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-304R, refer to GB/T8484-2008), the result shows GRP of thicknessof 50mm, K is 2.0W/m2K.

Fire resistance: class B. According to the test repot issued by National Center for Quality Supervision & Test of Fire Equipment (No.: Zb200921913), refer to GB8624-2006, the result achieves class B.

Smooth surface, up to 85% in light transmittance. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-305G), refer to GB/T2680-1994, GRP of thickness of 50mm, the transmittance is up to 85%. In sunny days, the illumination indoors can reach to 1000 lux. Refer to DIN 5035, the illumination in public place just needs 500 lux, and 200 lux is enough in workshop. Though it is high in transmittance, light pollution is not existed.

Sound isolation: 28dB. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-304S), refer to GB/T50121-2005, GRP of thickness of 50mm, sound isolation is 28dB.

Wonderful mechanical performance, which is shown in high elasticity and impact resistance. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-305DA), refer to GB/T9962-1999, result shows the vertical flexural strength is 131MPa, the lateral one is 124MPa, and the bending strength is more than 80MPa.

Long service life: at least 30years. GRP enjoys good performance in light and UV light resistance, and passed long-time exposure experiment.

High safety- hard to broken. Those doors, windows, curtain walls, partition panels, etc. used commonly in public areas, industrial plants and warehouses presently can be replaced to avoid maintenance in winter.

Light in weight: GRP of thickness of 50mm, it is 6.8Kg/m2 in weight.

It is of no pollution, and has good performance in erosion resistance (oxidation, acid, alkali, salt, oil and grease resistance). If destructive fire happens, GRP will be burned to be water, co2, co and dust, exclusive of nitride, sulfide, halogen or heavy metal. The product of combustion is low in toxicity, even lower than the one of pine, the result of smoke toxicity test is class ZA3.

- Q:Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Indeed, train or subway platforms can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles consist of a blend of reinforced fibers and a polymer resin matrix, endowing them with robustness and endurance. Their lightweight nature, resistance to corrosion, and exceptional mechanical properties make them suitable for diverse applications within the construction sector. Regarding train or subway platforms, FRP pultrusion profiles can serve as structural components, including handrails, guardrails, gratings, and decking systems. These profiles present a non-conductive and non-magnetic solution, crucial in railway environments to prevent interference with electrical and signaling systems. Furthermore, FRP pultrusion profiles offer a high degree of customization, enabling adaptation to specific project requirements. They can be crafted in various shapes, sizes, and colors to fulfill both aesthetic and functional demands in train or subway platforms. Moreover, FRP pultrusion profiles exhibit exceptional resistance against environmental factors such as moisture, chemicals, and UV radiation. This resistance ensures the profiles' durability and maintenance of their structural integrity over time, even in the harsh and corrosive conditions commonly encountered in railway environments. Overall, FRP pultrusion profiles represent a dependable and cost-effective choice for constructing train or subway platforms. They provide numerous advantages, including strength, durability, customization options, and resistance to environmental factors. Thus, they serve as a suitable alternative to conventional materials in these applications.

- Q:Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q:Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q:Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. These profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. They can be used in various aerospace applications including structural components, interior parts, and electrical systems. Additionally, their non-conductive properties make them suitable for applications where electrical insulation is required.

- Q:Are FRP pultrusion profiles resistant to UV degradation?

- FRP pultrusion profiles typically possess strong resistance against UV degradation. These profiles, constructed from a blend of resin and glass fibers, are designed to endure extended sun exposure. The resin utilized in their production is customarily engineered to provide UV radiation resistance. This resistance effectively safeguards the FRP pultrusion profiles from the detrimental effects of prolonged sunlight exposure. Extensive testing has confirmed the exceptional UV resistance of FRP pultrusion profiles. Consequently, they are frequently employed in outdoor settings, such as construction, infrastructure, and marine industries, where they are subject to sunlight exposure. The UV resistance guarantees that these profiles maintain their structural integrity, color, and aesthetic appeal over an extended period. However, it is crucial to acknowledge that the level of UV resistance may differ based on the specific resin formulation used during manufacturing. Various manufacturers employ different resins containing varying levels of UV stabilizers. It is advisable to consult the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are specifically designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also vital to ensure their long-term UV resistance. This may involve cleaning, applying protective coatings, or utilizing UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, securing their durability and longevity in outdoor environments.

- Q:Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in water treatment plants. FRP pultrusion profiles offer several advantages that make them well-suited for use in this industry. Firstly, FRP pultrusion profiles are highly corrosion resistant. Water treatment plants often have aggressive environments with exposure to chemicals and moisture, which can cause corrosion and degradation of traditional materials like steel. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratios. This means that they provide high structural integrity while being lightweight, making them easier to handle and install in water treatment plants. Additionally, their high strength allows them to withstand the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in water treatment plants, where there may be a need to isolate electrical equipment or components to prevent short circuits and protect personnel. FRP profiles provide a safe and reliable solution in such cases. Lastly, FRP pultrusion profiles have a long service life with minimal maintenance requirements. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. Overall, FRP pultrusion profiles are an excellent choice for use in water treatment plants due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life. Their use can contribute to improved efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q:Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in infrastructure projects. FRP pultrusion profiles offer several advantages over traditional materials such as steel and concrete. Firstly, FRP profiles are lightweight, yet still possess high strength-to-weight ratios. This makes them easier to transport and install, reducing construction time and costs. Additionally, their lightweight nature ensures they do not exert excessive loads on the supporting structures. Secondly, FRP profiles are corrosion-resistant. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects located in coastal areas or regions with high humidity. This corrosion resistance extends the service life of the structures and reduces maintenance requirements, resulting in long-term cost savings. Thirdly, FRP pultrusion profiles offer excellent durability and dimensional stability. They are highly resistant to fatigue, creep, and environmental degradation, ensuring the longevity and structural integrity of the infrastructure. Their dimensional stability also means that they maintain their shape and structural properties over time, reducing the risk of deformation or failure. Furthermore, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. Overall, the use of FRP pultrusion profiles in infrastructure projects offers numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits make FRP profiles a viable and cost-effective alternative to traditional materials for various infrastructure applications.

- Q:Are FRP pultrusion profiles electrically conductive?

- Typically, FRP pultrusion profiles lack electrical conductivity due to the utilization of a blend of fiberglass reinforcement and a thermosetting resin matrix. These components offer exceptional insulation qualities. The inherent non-conductive nature of the fiberglass reinforcement is further amplified by the resin matrix. Consequently, FRP pultrusion profiles find frequent application in situations where electrical conductivity is undesirable or poses safety hazards. Nevertheless, it is noteworthy that specific modifications or additions can be implemented during the pultrusion process to introduce electrical conductivity, if needed for particular applications.

- Q:How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles are an excellent choice for high-traffic areas due to their exceptional performance characteristics. These profiles are made of reinforced fiberglass and resin, resulting in a highly durable material that can withstand heavy loads and constant foot traffic. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lightweight yet incredibly strong, allowing them to handle heavy loads without sacrificing their structural integrity. Additionally, their non-corrosive nature makes them ideal for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is common. FRP pultrusion profiles also possess excellent resistance to wear and abrasion. This means that even in high-traffic areas, where constant footfalls and movement can cause conventional materials to deteriorate quickly, FRP profiles remain unaffected, maintaining their original appearance and functionality for an extended period. Furthermore, these profiles are highly resistant to UV radiation, which means they do not degrade or fade when exposed to sunlight. This is particularly important for high-traffic areas that are outdoors or have large windows, as the profiles will maintain their strength and aesthetics even under constant exposure to the sun. In terms of maintenance, FRP pultrusion profiles require minimal upkeep. They do not require regular painting or sealing, as their color and finish are built into the material itself. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. Overall, FRP pultrusion profiles are an excellent option for high-traffic areas due to their exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and constant foot traffic ensures their long-lasting performance, making them a reliable choice for any high-traffic environment.

- Q:What are the circumstances in which the pultrusion should be performed?

- (3) the heat deformation temperature of hot deformation temperature high extrusion is 186 DEG C, do not soften at high temperatures, -60 C constant crisp, to ensure the normal use of various environmental temperatures.(4) the water absorption is low, the water absorption of ordinary FRP products is less than 0.5%, while the water absorption rate of pultrusion section is only 0.257%, which is suitable for use in humid environment(5) heat transfer coefficient and low coefficient of thermal insulation rigid PVC pultruded profile approach, made with the single frame double glass insulating window insulation coefficient is only 2.69W/ (M2? K), while the thermal insulation coefficient of the same type of steel, aluminum window made up of 4.0W/ (M2? K). Show that the energy saving glass steel doors and windows is obvious.(6) strong corrosion resistance pultruded profile by 3%HCI solution for 24h, its hardness retention rate was 95%; the 3%NaCl solution for 24h, its hardness retention rate of 89%. so the FRP pultruded profiles for making doors and windows is not only suitable for general residential houses, hotels, restaurants, and more suitable for coastal areas and the corrosive working environment of industrial plant use.(7) to meet the requirements of the environment, the production process of the extruded section has the characteristics of low noise, high efficiency, low power consumption, low pollution, etc., and it conforms to the relevant environmental requirements of the state

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBER REINFORCE PLASTIC Transparancy Skylight Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords