Gear shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

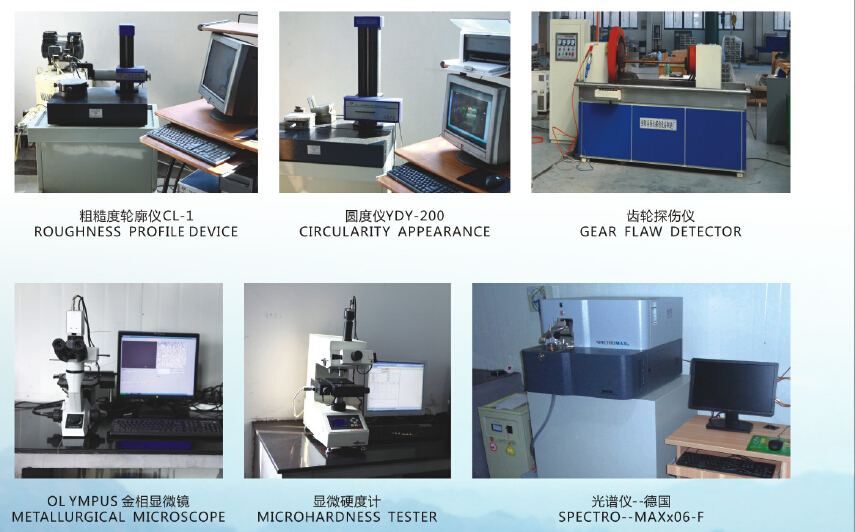

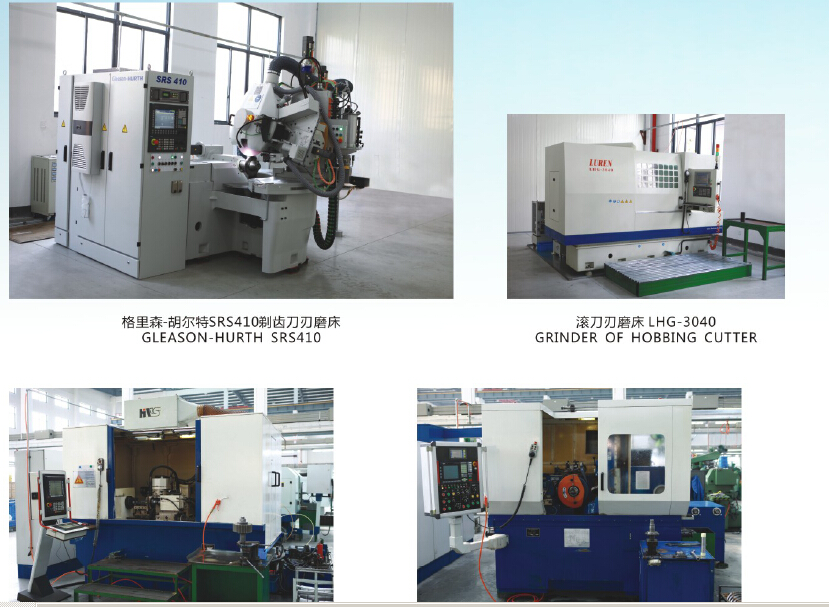

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q:Processing technology of external gear ring for help

- 4. Grinding: grinding (or grinding the amount of fine grinding) 5. rolls: tooth products (if it is 7 level precision) 6. pliers: deburring 7. heat: tooth high frequency

- Q:How does the gear ring match the starter? Is there a method of calculating the work type? Tell me about it. Thank you

- The two parameters, the modulus m of the starter gear and the pressure angle alpha, can only be deduced

- Q:How is the thickness of the outer ring (outer diameter and internal diameter) determined?

- The magnitude of the torque transmission is different and the gear modulus adopted is different. Modulus is not the same

- Q:The role of automobile gear ring

- Gear shifting of transmission, especially shift from high-grade to low gear, is more complicated, and it is easy to produce impact between gear teeth or spline teeth. In order to simplify the operation and avoid the impact between the teeth, a synchronizer can be set in the gear shift device. An inertial synchronizer is synchronized by friction, and a special mechanism is arranged on it to ensure that the engagement ring and the spline gear ring to be joined can not be contacted before the synchronization is achieved, thus avoiding the impact between teeth. Hope to help you, please also set the best answer! Thank you

- Q:How to install the gear ring of the rear oil seal of Lang Yi crankshaft?

- That way you can start?. The fire is a bit late. What else can you do?

- Q:Why does the radial runout of the gear ring reveal only the geometric eccentricity of the gear?

- That's one of the main reasons:1, the material uniformity is poor.

- Q:1115 how many teeth are used when the diesel engine is switched on?

- If there are any problems in the above, please fix or replace it.

- Q:Flywheel ring gear with 167 teeth with several teeth motor

- The 6114A-143 6114B-125 WD615 has 136 teeth, Victoria tooth has 159 teeth, two teeth with different Ma Dachi

- Q:The number of planet gear is 20, the drive ratio is 7.5. The number of teeth of solar wheel and ring gear is required

- That is in direct contact with the center of the planetary gear wheel or tied as the driving link drives a planetary gear, a planetary wheel around its axis of rotation O1-O1, on the other hand, with the development of component H (or tied) around a fixed axis (O-O axis rotary wheel center)

- Q:About diesel electromechanical starter flywheel gear ring and flywheel

- The assembly process in the factory is to heat the gear ring. Because of the expansion and contraction, the gear ring will become slightly larger so that it can be assembled with the flywheel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gear shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords