Galvanized Accessories of Ceiling System Galvanized Accessories of Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

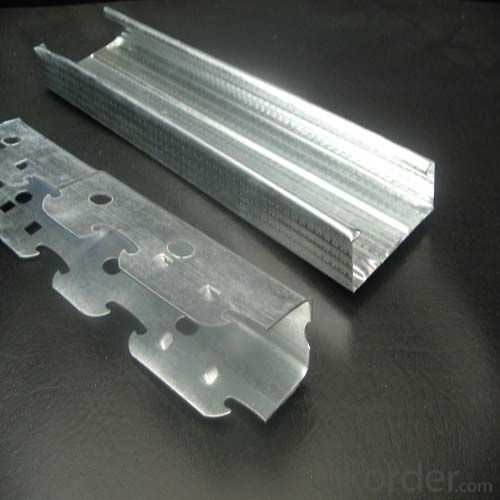

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

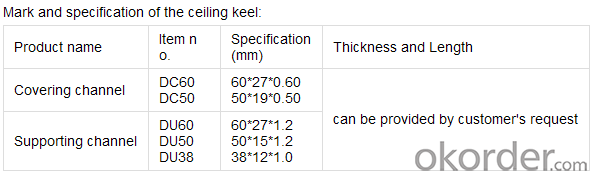

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q:I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- No, gypsum board is too brittle easy to rotten

- Q:Ordinary light steel keel gypsum board ceiling budget sets which quota

- Ordinary flattened around with a light bulb, then 120 yuan per square meter Shaped 180 yuan per square meter Below this price you can not make money

- Q:Light steel keel ceiling how to read complex drawings

- Do the work of the words do not matter how the light steel keel ceiling how to do a project to do in-depth understanding of the project because there are many national norms limit, how to understand the drawings, you need to have some theoretical knowledge, plus more to the site to see how workers Construction, ie theory + reality

- Q:What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- The ceiling will basically do not use the wooden keel are flat top steel keel shape top directly with blockboard and 9mm board 5mm board to do modeling such as oval shape

- Q:Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q:Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel backing, after the order made with gypsum board! Grille Ceilings I feel better!

- Q:Ceiling light steel keel specifications are models which several

- Wall keel main specifications are divided into Q50, Q75, Q100 and Q150. Ceiling keel main specifications are divided into D38, D50 and D60 and so on. According to their cross-sectional shape is divided into U-type, C-type, T-type, H-type, V-type, L-type, CH-type seven, light steel keel mark the order: product name, code, cross-sectional shape of the width, Thickness and standard number. Customers should be based on process and decoration requirements, decided to use the wall keel, ceiling keel and specifications and cross-sectional shape.

- Q:Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- The kind of keel is determined by the material of the ceiling. Light steel keel for, gypsum board, integrated ceiling, relief gypsum board mineral wool board (both bones for the paint). Kitchen and other basic not suitable, integrated ceiling can be. If only the ordinary buckle top, it must be wood keel, or can not be fixed pinch. On the issue of cost-effective, light steel keel and wood keel basically no comparable, the same area of the former price of the latter twice as much as the latter, but iron is better than wood. Home improvement basically no light steel keel, because the kitchen is not suitable, in the living room after the ceiling height than the keel to 10 cm lower.

- Q:Play light steel keel cut off how not to damage the ceiling

- Can be found after the next day keel fixed, the other side can be used to do vertical keel shape, and then package edge

- Q:What is the light steel keel?

- Light steel (paint) keel, is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction, etc., by the user and the design unit widely used. Light steel keel and paint keel is the difference between the general light steel keel is not painted surface treatment, making coating (galvanized), and paint keel surface made paint, generally divided into black and white, a few according to the design requirements baked into other colors, Mainly because most of the paint keel used in the Ming keel, paint is to ensure that the exposed part of the rust does not affect the appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Accessories of Ceiling System Galvanized Accessories of Ceiling System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords