Drywall Metal Studs and Tracks for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

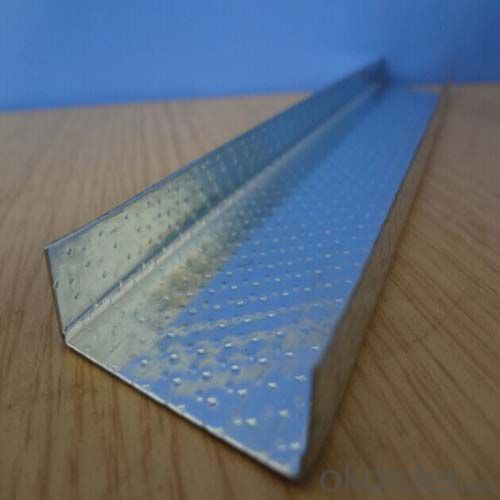

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3.Image

4.Detailed Specification

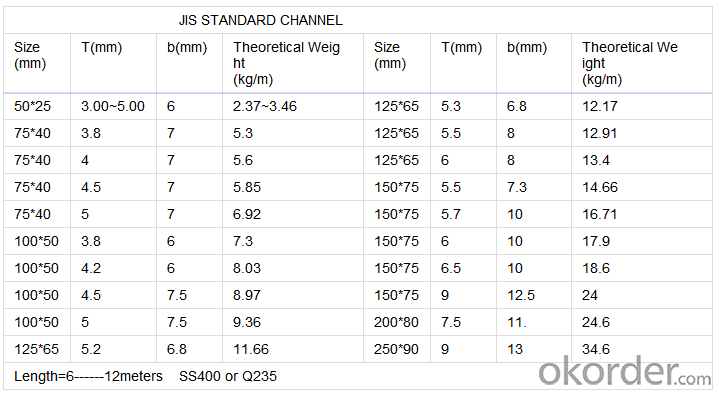

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

9. slit edge or mill edge.

10. Any third party inspection can accept.

- Q:Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

- Q:What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- The ceiling will basically do not use the wooden keel are flat top steel keel shape top directly with blockboard and 9mm board 5mm board to do modeling such as oval shape

- Q:Tectonic hierarchy of light steel keel

- Material purchase requirements 1. Light steel skeleton sub-U-shaped skeleton and T-skeleton two, according to the load and not on the master. 2. Light steel skeleton main pieces for large, medium and small keel; accessories hanging pendant, connectors, hanging plug. 3. Spare parts: a boom. Flower blue screws. Nail. Self-tapping screws. 4. According to the design can choose a variety of cover panels. Aluminum pressure or plastic pressure every bar, the material varieties. Specifications. Quality should meet the design requirements. 5. Binder: should be selected according to the performance of the main material, before use for bonding test.

- Q:Light steel keel second ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling.

- Q:Ceiling light steel keel specifications are models which several

- Wall keel main specifications are divided into Q50, Q75, Q100 and Q150. Ceiling keel main specifications are divided into D38, D50 and D60 and so on. According to their cross-sectional shape is divided into U-type, C-type, T-type, H-type, V-type, L-type, CH-type seven, light steel keel mark the order: product name, code, cross-sectional shape of the width, Thickness and standard number. Customers should be based on process and decoration requirements, decided to use the wall keel, ceiling keel and specifications and cross-sectional shape.

- Q:Light steel keel good or fir Fang Fang dragon skeleton good

- Light steel keel is good, will not be damp, will not be deformed, but not easy to do modeling, so there are a lot of home improvement with wood keel, because it is easy to do a variety of shapes, but to brush on the moisture and fire paint. 1, according to the order of operation. 2, wood keel no knots, wood keel then long to link firmly, boom and wood keel, floor link firmly. 3, keel should be painted fire anticorrosive coating. 4, suspended keel to consider the future sagging, so after installation, the center should be short side of the arch from 1/200. 5, where a lampshade, curtain box and other positions should increase the keel, ceiling fan shall not be in the dragon on the skeleton. 6, cover the panel should be flat, no Qiaojiao, from the skin, degumming and other phenomena, if the parquet, the design should be the design requirements. Slats, steel mesh plaster top 1, wood keel grid with the wooden ceiling. 2, lath joints must be staggered, the board should not be too light, slats and steel mesh are nailed. 3, lime paste must be fully mature, do not allow lime fixed particles, so as not to plaster from the bubble after the bubble. 4, slag dry, easy to water swelling, after the plaster dry and easy to crack, so the end of the ash should be sprayed with water after wetting, and then wipe the leveling layer to combine with each other. Light steel keel ceiling 1, the selection of light steel keel should meet the design requirements to ensure quality. 2, all in the ceiling of spare parts, keel should be galvanized pieces. 3, keel, boom, connectors should be the right position, the material formation, straight, connected firmly, no loosening.

- Q:Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- Certainly light steel keel wood keel is not fire waterproof

- Q:Light steel keel ceiling than the wooden keel ceiling a square how much you ah?

- Not expensive wood to do light steel keel specifications even more expensive

- Q:Light steel keel ceiling steps? How to use wood?

- Step 1: the line is the roof with ink cartridges hanging wire and ceiling height of the wall set. ??????? 2: roof bolts with hanging bolts ??????? 3: according to the needs of the height of the ceiling cut off the length of hanging wire hanging wire ??????? 4: nail keel corner ??????? 5: set up the main keel and hanging wire with fastening, need to hang the line to pursue the top of the flatness ??????? 6: laying the vice keel If it is mineral wool board keel size is fixed mostly 50X50 cm if it is gypsum board then it is wide 40X40 cm three meters long set joint keel (gypsum board size is 120X300 unit centimeters) ??????? 7: laying the process of laying the decorative lights and the main light of the fastening plate (decoration workers love to board the board when the light on a very good amount of tight screws)

- Q:Wood keel and light steel keel were used for where?

- Wood keel is generally used in the living room and aisle ceiling, light steel keel used in the kitchen bathroom ceiling

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Studs and Tracks for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords