FRP Roofing Panel S15

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

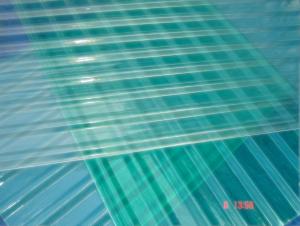

Specification of FRP Roofing Panel S15

Thickness:2.0mm

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.Ordinary Wave: 950-237,

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel S15:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery of FRP Roofing Panel S15:

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q:Can FRP roofing panels be used for architectural or design purposes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used for architectural or design purposes. FRP panels are versatile and can be molded into various shapes and sizes, allowing for creative and unique designs. They can be used to create modern and sleek architectural structures or add interesting design elements to existing buildings. Additionally, FRP panels come in a wide range of colors and finishes, giving architects and designers the flexibility to match or contrast with the surrounding environment. FRP panels are also lightweight, durable, and resistant to corrosion, making them ideal for architectural and design applications.

- Q:Are FRP roofing panels resistant to pests and insects?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to pests and insects. The composition of FRP panels, which consists of a strong fiberglass matrix, makes them less attractive to pests and insects. Additionally, FRP panels are typically installed in a way that minimizes any potential entry points for pests, further reducing the risk of infestation. However, it is important to note that no roofing material is entirely immune to pests, and regular inspections and maintenance are still recommended to prevent any potential issues.

- Q:Are FRP roofing panels suitable for gymnasiums or sports facilities?

- Yes, FRP roofing panels are suitable for gymnasiums or sports facilities. They offer a range of benefits such as durability, lightweight construction, resistance to weather elements, and low maintenance requirements. Additionally, their translucency allows for natural lighting, creating a pleasant environment for athletes and reducing the need for artificial lighting during the day. Overall, FRP roofing panels are a practical and efficient choice for gymnasiums or sports facilities.

- Q:Do FRP roofing panels require edge trims or flashing?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically require edge trims or flashing. Edge trims are used to create a clean and finished look at the edges of the panels while providing protection against water infiltration and wind lift. They also help to prevent any sharp edges from being exposed, reducing the risk of injury. Flashing is another essential component for FRP roofing panels as it helps to redirect water away from the edges and joints, preventing any potential leaks or water damage. Overall, using edge trims and flashing is highly recommended for FRP roofing panels to ensure proper installation, protection, and longevity of the roof.

- Q:Are FRP roofing panels resistant to warping or sagging?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping or sagging. This is because FRP panels have a high strength-to-weight ratio, which allows them to maintain their structural integrity even under significant load or temperature changes. The fiberglass reinforcement in FRP panels provides excellent stiffness and rigidity, preventing any noticeable warping or sagging over time. Additionally, FRP panels are designed to withstand extreme weather conditions, including high winds, heavy rain, and intense sunlight, further ensuring their resistance to warping or sagging. Overall, FRP roofing panels are a durable and reliable option that can maintain their shape and structural integrity for an extended period.

- Q:Can FRP roofing panels withstand extreme weather conditions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and ability to withstand extreme weather conditions. One of the key advantages of FRP roofing panels is their high impact resistance, which allows them to withstand strong winds, heavy rain, hail, and even extreme temperature fluctuations. FRP panels are made of a composite material that combines fiberglass and resin, providing them with excellent strength and resilience. Furthermore, FRP panels are also UV resistant, which means they can withstand prolonged exposure to sunlight without fading or degrading. Overall, FRP roofing panels are designed to endure harsh weather conditions, making them a reliable choice for various applications.

- Q:Do FRP roofing panels require any special precautions during installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require special precautions during installation to ensure proper installation and longevity of the roof. Some of the key precautions to keep in mind are: 1. Safety Measures: It is essential to follow appropriate safety precautions during installation. This includes wearing protective gear such as gloves, safety glasses, and a dust mask to prevent any injuries or inhalation of fiberglass particles. 2. Proper Handling: FRP panels are relatively lightweight, but they can be fragile and prone to damage. It is important to handle the panels with care and avoid dropping or dragging them to prevent cracks or breakages. 3. Acclimation: FRP panels should be acclimated to the temperature and humidity conditions of the installation site before installation. This helps prevent any potential warping or dimensional changes that may occur due to expansion or contraction. 4. Temperature Considerations: Installers should be aware of the temperature limitations specified by the manufacturer. Extreme temperatures can affect the integrity and appearance of FRP panels. For example, installing panels in very cold conditions can make them more brittle and prone to cracking. 5. Proper Fastening: FRP panels need to be securely fastened to the roof structure using appropriate fasteners recommended by the manufacturer. It is crucial to follow the recommended fastening pattern and spacing to ensure the panels are properly secured in place. 6. Expansion and Contraction: FRP panels can expand and contract with changes in temperature. To accommodate these movements, it is important to leave adequate space for thermal expansion and contraction during installation. Additionally, using fasteners with some flexibility, such as neoprene washers, can help absorb the movements and prevent stress on the panels. 7. Sealant and Flashing: Proper sealing and flashing are crucial to prevent water infiltration and ensure a watertight installation. Installers should use compatible sealants and flashing materials recommended by the manufacturer to achieve a durable and weather-resistant roof. Overall, following the manufacturer's installation guidelines and recommendations is essential for a successful installation of FRP roofing panels. It is also recommended to consult with a professional roofing contractor for expert advice and assistance to ensure the panels are installed correctly and safely.

- Q:Can FRP roofing panels be used for walkways or bridges?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for walkways or bridges. FRP panels are known for their durability, high strength-to-weight ratio, and resistance to corrosion and weathering. These properties make them suitable for various applications, including walkways and bridges. FRP panels can provide a safe and stable surface for pedestrians and can withstand heavy foot traffic or loads typically found on bridges. Additionally, FRP panels are lightweight, which makes them easier to install and transport compared to traditional materials like steel or concrete. They are also available in various sizes, shapes, and colors, allowing for customization to meet specific design requirements. Overall, FRP roofing panels are a great choice for walkways or bridges due to their strength, durability, and versatility.

- Q:Can FRP roofing panels be used in high-temperature environments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in high-temperature environments. These panels are designed to be heat-resistant and can withstand elevated temperatures without warping or deforming. They are often used in industrial settings, such as chemical plants or factories, where high temperatures are common. However, it is important to consider the specific temperature limits and recommendations provided by the manufacturer to ensure the panels are suitable for the intended high-temperature application.

- Q:Can FRP roofing panels be used for zoos?

- Zoos can utilize FRP roofing panels due to their durability, strength, and resistance to environmental elements. These panels are suitable for various applications, including zoos, where animal safety is paramount. When it comes to zoos, the use of FRP roofing panels brings several advantages. Firstly, they are lightweight yet robust, ensuring a secure and dependable roofing solution, especially in areas prone to heavy snow loads or strong winds. Secondly, FRP panels possess exceptional resistance against UV radiation, preventing fading, discoloration, or degradation caused by prolonged sun exposure. This is vital for maintaining the zoo's aesthetics and ensuring visually pleasing enclosures for the animals. Furthermore, FRP roofing panels exhibit low thermal conductivity, which aids in regulating the temperature within the enclosures. This contributes to a more comfortable and controlled environment for the animals. Additionally, these panels provide excellent insulation, resulting in energy efficiency and reduced heating or cooling costs. Moreover, FRP roofing panels offer a wide range of colors, textures, and designs, enabling zoo designers to create visually appealing enclosures that mimic natural habitats. This enhances the overall experience for visitors while providing a more stimulating and enriching environment for the animals. In conclusion, FRP roofing panels serve as a versatile and reliable roofing solution for zoos. Their durability, resistance to environmental factors, and aesthetic options make them a suitable choice for creating safe and visually appealing enclosures for animals.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel S15

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords