FRP Molded Grating /GRP Grating / FRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Aging Resistance

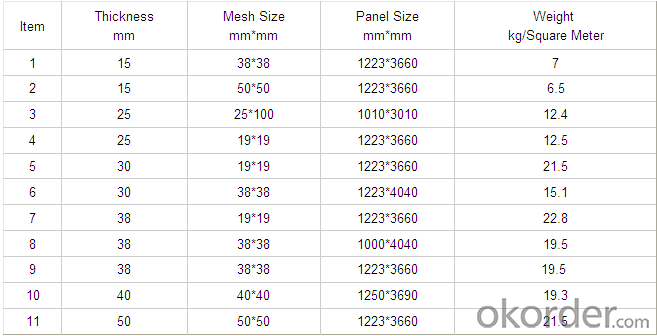

Specification

Advantage

coated with prevent aging layer

- high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

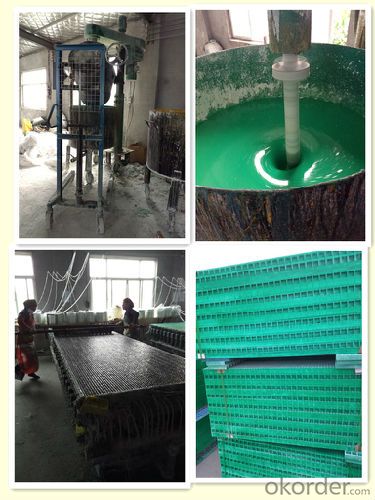

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to impact and vibration?

- FRP pultrusion profiles possess a high level of resistance to impact and vibration, thanks to their composition and manufacturing process. These profiles are inherently durable and strong due to the combination of resins and fibers used. The fibers, commonly glass or carbon, contribute to their excellent tensile strength, while the resin matrix adds toughness and impact resistance. The unique composition of FRP pultrusion profiles allows them to absorb energy effectively, enabling them to withstand impacts without significant deformation or damage. This quality makes them well-suited for applications that necessitate impact resistance, such as construction, transportation, and infrastructure projects. Furthermore, FRP pultrusion profiles exhibit exceptional vibration resistance. The composite material's inherent damping characteristics help disperse and dampen vibrations, minimizing the risk of structural fatigue and increasing the profiles' lifespan. This makes them ideal for use in environments with heightened vibration levels, including industrial machinery, bridges, and marine structures. Nevertheless, it is crucial to consider that the impact and vibration resistance of FRP pultrusion profiles may vary based on factors such as resin type, reinforcement fibers, and profile design. Thus, it is advisable to consult the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles fulfill the specific impact and vibration resistance requirements of the intended application.

- Q:Are FRP pultrusion profiles resistant to UV degradation?

- FRP pultrusion profiles typically possess strong resistance against UV degradation. These profiles, constructed from a blend of resin and glass fibers, are designed to endure extended sun exposure. The resin utilized in their production is customarily engineered to provide UV radiation resistance. This resistance effectively safeguards the FRP pultrusion profiles from the detrimental effects of prolonged sunlight exposure. Extensive testing has confirmed the exceptional UV resistance of FRP pultrusion profiles. Consequently, they are frequently employed in outdoor settings, such as construction, infrastructure, and marine industries, where they are subject to sunlight exposure. The UV resistance guarantees that these profiles maintain their structural integrity, color, and aesthetic appeal over an extended period. However, it is crucial to acknowledge that the level of UV resistance may differ based on the specific resin formulation used during manufacturing. Various manufacturers employ different resins containing varying levels of UV stabilizers. It is advisable to consult the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are specifically designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also vital to ensure their long-term UV resistance. This may involve cleaning, applying protective coatings, or utilizing UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, securing their durability and longevity in outdoor environments.

- Q:Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that allows for the creation of complex shapes and sizes, making it possible to tailor the FRP profiles to meet specific design and performance criteria. This customization can include modifications in dimensions, reinforcement types, resin systems, color, surface finish, and various other parameters to ensure they meet the desired specifications and needs of the application.

- Q:Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q:Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction industry. FRP pultruded profiles offer several advantages that make them suitable for various construction applications. Firstly, FRP pultrusion profiles are lightweight yet exceptionally strong. This makes them an excellent choice for construction projects as they provide high strength-to-weight ratio, reducing the overall weight of the structure while maintaining structural integrity. This can be particularly advantageous in applications such as bridges, walkways, and platforms. Secondly, FRP pultrusion profiles are highly corrosion resistant. Unlike traditional construction materials like steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. This makes FRP profiles ideal for outdoor or marine applications where corrosion is a concern, such as seawalls, docks, or offshore structures. Additionally, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized, such as electrical enclosures or cable trays. FRP profiles also have low thermal conductivity, which can help improve energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They have a long service life and do not require regular painting, sealing, or treatment like traditional materials. This can result in significant cost savings over the life cycle of a construction project. Lastly, FRP pultrusion profiles can be designed to meet specific strength, stiffness, and dimensional requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in design and customization. This versatility makes FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. In summary, FRP pultrusion profiles are a viable option for the construction industry due to their lightweight, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q:Can FRP pultrusion profiles be used in agricultural applications?

- Indeed, FRP pultrusion profiles are applicable in the field of agriculture. Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles are an ideal choice for a variety of agricultural uses. One common utilization of FRP pultrusion profiles in agriculture is the construction of livestock enclosures, encompassing fences, gates, and pens. These profiles possess outstanding resistance to weather conditions, chemicals, and degradation caused by UV rays, ensuring their long-lasting performance in outdoor environments. Furthermore, their lightweight composition facilitates ease of handling and installation. Moreover, FRP pultrusion profiles find application in the production of agricultural equipment and machinery. They can be employed for structural components, such as beams and supports, as well as functional parts like handles, brackets, and covers. The impressive strength of FRP profiles enables them to withstand heavy loads and challenging operating conditions, while their resistance to corrosion guarantees their longevity in corrosive surroundings such as fertilizer storage areas or livestock waste management systems. Additionally, FRP pultrusion profiles can be utilized for irrigation systems in agriculture. Their non-conductive nature renders them perfect for situations requiring electrical insulation, such as the creation of irrigation pipes or channels. Furthermore, the corrosion resistance of FRP profiles ensures their ability to endure exposure to water, chemicals, and fertilizers frequently employed in agricultural irrigation. To summarize, FRP pultrusion profiles exhibit exceptional suitability for agricultural applications due to their high strength, resistance to corrosion, and durability. Whether employed in livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer numerous advantages that position them as a reliable choice within the agricultural industry.

- Q:Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture and humidity. The pultrusion process involves impregnating continuous fibers with a polymer resin, resulting in a strong and durable composite material. This composite is inherently moisture-resistant and does not absorb water like traditional materials such as wood or metal. Additionally, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they are less likely to expand or contract under varying levels of humidity. This resistance to moisture and humidity makes FRP pultrusion profiles suitable for a wide range of applications, including outdoor structures, marine environments, and other moisture-prone areas.

- Q:Are FRP pultrusion profiles resistant to fading or discoloration?

- FRP pultrusion profiles possess exceptional resistance against fading and discoloration. This attribute stems from the inherent properties of the materials employed in their construction. Typically, FRP profiles are fabricated using a blend of fiberglass reinforcements and a polymer resin matrix, both of which inherently resist UV radiation and other environmental factors that lead to fading and discoloration. The polymer resin matrix used in FRP profiles is specifically designed to exhibit outstanding chemical resistance and UV stability. As a result, the profiles retain their original color and appearance for an extended duration. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and harsh weather conditions is prevalent. Additionally, the pultrusion manufacturing process ensures that the color of FRP profiles remains consistent throughout their entire cross-section. Consequently, even in the presence of minor surface damage or wear, the underlying color of the profile remains unchanged, ensuring a uniform appearance. In summary, FRP pultrusion profiles offer unparalleled resistance against fading and discoloration, making them a resilient and long-lasting option for a wide range of applications, including construction, infrastructure, transportation, and more.

- Q:Can FRP pultrusion profiles be used in the construction of solar panel frames?

- Yes, FRP pultrusion profiles can be used in the construction of solar panel frames. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for supporting and protecting solar panels. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in constructing solar panel frames.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating /GRP Grating / FRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords