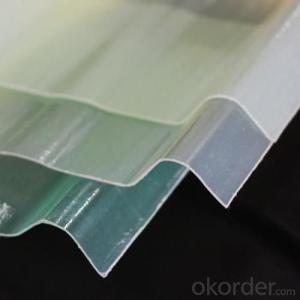

FRP Corrugated Roof Sheets Fiberglass Corrugated Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q:Can FRP roofing panels be installed on curved surfaces?

- FRP roofing panels have the capability to be installed on surfaces that are curved. These panels possess flexibility and can be effortlessly shaped to accommodate the contours of curved roofs. By bending and molding the panels, the desired curve can be achieved, resulting in a flawless and stable installation. However, it is crucial to acknowledge that the extent of curvature might influence the size and shape of the required panels. Additionally, additional considerations, such as appropriate support and fastening methods, may be necessary in order to ensure the panels are securely affixed to the curved surface. To ensure accurate guidance on installing FRP roofing panels on curved surfaces, it is recommended to seek advice from a professional installer or manufacturer.

- Q:Are FRP roofing panels suitable for ice and snow regions?

- Considering ice and snow regions, FRP roofing panels possess specific qualities that render them appropriate. Nonetheless, it is important to take certain factors into account. Durability stands out as one of the key advantages of FRP roofing panels in cold climates. They exhibit remarkable resistance to impact, cracking, and splitting, which is critical when confronted with heavy snowfall and ice accumulation. Moreover, FRP panels do not absorb moisture, preventing them from becoming brittle or warping when exposed to freezing temperatures. Additionally, they possess high corrosion resistance, avoiding rot or rust, making them optimal for regions with severe winter weather. Another element to consider is the thermal conductivity of FRP roofing panels. They boast low thermal conductivity, implying that heat transfer is not easily facilitated. This attribute proves advantageous in ice and snow regions as it helps thwart the formation of ice dams on the roof. Ice dams occur when heat from the interior of the building escapes through the roof, causing snow to melt and refreeze at the roof edges. FRP panels assist in maintaining a consistent temperature on the roof surface, minimizing the risk of ice dams. Nevertheless, it is crucial to acknowledge that FRP roofing panels are not completely immune to ice and snow-related issues. Similar to other roofing materials, they can accumulate snow and ice, necessitating periodic removal to prevent excessive roof weight. Furthermore, proper installation and insulation are vital to ensure optimal performance of the panels in cold climates. Sufficient ventilation and insulation in the attic space can aid in preventing the formation of ice dams and reducing heat loss. In conclusion, FRP roofing panels can be a suitable option for ice and snow regions due to their durability, resistance to moisture and corrosion, as well as their low thermal conductivity. However, consulting a professional and ensuring proper installation and maintenance are essential to maximize their effectiveness in these specific climatic conditions.

- Q:Can FRP roofing panels be used for loading docks or truck shelters?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for loading docks or truck shelters. FRP panels are known for their durability and strength, making them suitable for heavy-duty applications such as loading docks and truck shelters. They are resistant to corrosion, impact, and weather conditions, making them a reliable choice for outdoor structures. Additionally, FRP roofing panels are lightweight, which makes installation and maintenance easier. They are also available in various sizes and colors, allowing for customization to fit specific requirements. Overall, FRP roofing panels are a cost-effective and long-lasting solution for loading docks and truck shelters.

- Q:Can FRP roofing panels be installed over different roof substrates (e.g., concrete, metal)?

- Yes, FRP roofing panels can be installed over different roof substrates including concrete and metal. FRP panels are versatile and can be easily installed on various surfaces, making them suitable for different types of roofs. However, it is important to ensure proper installation techniques are followed to ensure a secure and long-lasting installation.

- Q:Do FRP roofing panels provide good insulation?

- FRP roofing panels, also known as Fiberglass Reinforced Plastic panels, do not provide good insulation on their own. While FRP panels are known for their durability, strength, and resistance to weather elements, they are not designed to be effective insulators. Insulation primarily depends on the material used and the thickness of the panel. FRP panels are typically thin, and their main purpose is to provide protection and durability for the roofing structure rather than thermal insulation. If insulation is a concern, it is advisable to consider additional insulation measures such as using insulation boards, foam panels, or other thermal insulating materials in conjunction with FRP panels. This will help to enhance the overall insulation performance of the roofing system, ensuring better temperature control and energy efficiency.

- Q:Are FRP roofing panels suitable for green buildings?

- Yes, FRP roofing panels are suitable for green buildings. FRP stands for Fiberglass Reinforced Plastic, which is a durable and lightweight material that is often made from recycled materials. These panels offer excellent insulation properties, reducing the need for excessive heating or cooling in the building. Additionally, FRP panels are resistant to corrosion, UV rays, and extreme weather conditions, making them a sustainable and long-lasting roofing option for green buildings.

- Q:Can FRP roofing panels be used for swimming pool enclosures or covers?

- Yes, FRP roofing panels can be used for swimming pool enclosures or covers. FRP (Fiberglass Reinforced Plastic) panels are known for their durability, resistance to moisture, and transparency, making them suitable for enclosing or covering swimming pools. They offer protection from external elements while allowing natural light to pass through, creating an ideal environment for swimming.

- Q:Are FRP roofing panels impact-resistant?

- FRP roofing panels exhibit resistance to impact and are acknowledged for their high strength-to-weight ratio, rendering them a robust material for roofing purposes. They possess the ability to endure the impact of hail, falling debris, and other potential causes of harm. Moreover, FRP panels are constructed to possess flexibility, aiding in the absorption and dispersion of impact force, thus minimizing the possibility of cracks or breakage. Nevertheless, it is crucial to acknowledge that the degree of impact resistance may vary contingent upon the specific manufacturer and product. It is advisable to peruse the manufacturer's provided specifications prior to procuring FRP roofing panels to ascertain their conformity with the desired impact resistance prerequisites.

- Q:Can FRP roofing panels be used in churches or religious buildings?

- Yes, FRP roofing panels can be used in churches or religious buildings. FRP panels are lightweight, durable, and offer excellent weather resistance, making them suitable for various architectural applications. They can withstand extreme temperatures, UV radiation, and are designed to provide long-lasting protection. Additionally, FRP panels can be customized to match the aesthetics of the church or religious building, allowing for a seamless integration with the overall design.

- Q:Are FRP roofing panels resistant to cracking?

- FRP roofing panels possess a remarkable resistance to cracking, owing to their composition of a robust fiberglass layer fortified with a polymer resin. This construction renders them exceptionally durable and impervious to a range of damages, including cracks. The fiberglass layer endows the panels with exceptional strength and flexibility, enabling them to endure heavy impacts and withstand cracking even in the face of severe weather conditions like hailstorms or strong winds. Furthermore, FRP roofing panels are often formulated with special additives that further augment their resistance to cracking. Nevertheless, it is crucial to acknowledge that while FRP panels demonstrate a high resistance to cracking, their durability can vary based on the specific brand, quality, and method of installation. Therefore, it is advisable to seek guidance from a professional roofing contractor or manufacturer to ensure the correct installation and maintenance of FRP roofing panels, thus ensuring optimal performance and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Corrugated Roof Sheets Fiberglass Corrugated Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords