Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

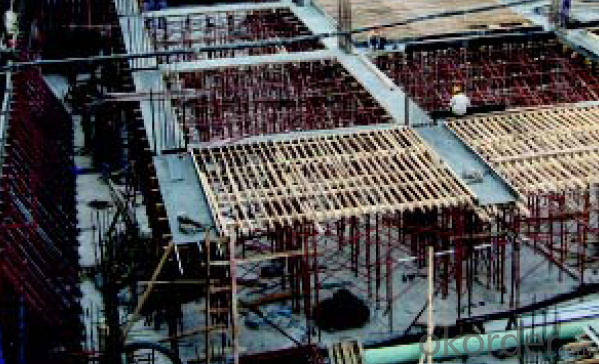

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:Are there any specific guidelines for the safe use of steel tube couplers in scaffolding near areas with high temperatures or heat sources?

- Specific guidelines exist for the safe use of steel tube couplers in scaffolding near high temperatures or heat sources. To ensure the safety and integrity of the scaffolding structure, adherence to these guidelines is essential. Consider the following key points: 1. Heat resistance: Steel tube couplers used in scaffolding must be constructed from materials capable of withstanding high temperatures without compromising structural integrity. To ensure safety, it is advisable to use couplers made from heat-resistant alloys or materials like stainless steel. 2. Material selection: It is crucial to select steel tube couplers explicitly designed and manufactured for use in high-temperature environments. These couplers should be capable of enduring the heat generated by nearby sources such as welding operations or high-temperature equipment. 3. Insulation: In areas with high temperatures or heat sources, proper insulation techniques should be employed to safeguard the scaffolding structure. Insulating materials like fire-resistant blankets or shields can be utilized to prevent excessive heat transfer to the steel tube couplers. 4. Regular inspections: Regular inspections of scaffolding structures near high-temperature areas are imperative to identify any signs of damage or deformation. Any couplers displaying indications of heat-related damage, such as warping or discoloration, should be promptly replaced to maintain the structural integrity of the scaffolding. 5. Training and awareness: Workers involved in erecting or dismantling scaffolding near high-temperature areas should undergo appropriate training regarding the safe use of steel tube couplers in such environments. They should be mindful of the potential risks associated with high temperatures and heat sources and be equipped with knowledge on how to mitigate them. 6. Compliance with standards: It is crucial to comply with pertinent safety standards and regulations specifically addressing scaffolding and high-temperature environments. These standards provide guidelines for the secure utilization of steel tube couplers and other scaffolding components in challenging conditions. By adhering to these guidelines, scaffolding structures near high temperatures or heat sources can be erected and maintained safely, thus minimizing the risk of accidents or structural failures. It is important to consult industry experts or regulatory bodies to ensure compliance with the most up-to-date safety standards and best practices.

- Q:Are there any specific guidelines for the safe use of steel tube couplers in scaffolding near areas with high levels of airborne contaminants or pollutants?

- Yes, there are specific guidelines for the safe use of steel tube couplers in scaffolding near areas with high levels of airborne contaminants or pollutants. When working in such environments, it is essential to take appropriate measures to protect the health and safety of workers. 1. Risk Assessment: Conduct a thorough risk assessment to identify potential hazards associated with the airborne contaminants or pollutants present in the area. This assessment should consider the type, concentration, and toxicity of the contaminants. 2. Select Appropriate Materials: Choose steel tube couplers that are resistant to corrosion and deterioration caused by the specific contaminants present in the environment. Ensure that the couplers are made from high-quality materials that can withstand exposure to the airborne pollutants. 3. Regular Inspections: Regularly inspect the steel tube couplers to identify any signs of corrosion, deterioration, or damage that may compromise their integrity. Replace any couplers that show signs of wear and tear or are no longer fit for use. 4. Protective Measures: Implement suitable protective measures to minimize workers' exposure to the airborne contaminants. This may include providing appropriate personal protective equipment (PPE) like respirators, gloves, and protective clothing. Encourage workers to follow proper hygiene practices, such as washing hands and face after work. 5. Training and Education: Provide comprehensive training to workers regarding the potential hazards associated with working in areas with high levels of airborne contaminants or pollutants. Train them on the proper use of PPE and safe work practices to minimize exposure risks. 6. Adequate Ventilation: Ensure that the scaffolding area has adequate ventilation to reduce the concentration of airborne contaminants. This can be achieved by using fans, air purifiers, or by positioning the scaffolding in areas with better air quality. 7. Maintenance and Cleaning: Regularly clean and maintain the scaffolding equipment, including the steel tube couplers, to prevent the accumulation of contaminants that could compromise their structural integrity. 8. Compliance with Regulations: Ensure compliance with all relevant safety regulations, standards, and guidelines set by local authorities and regulatory bodies. Adhere to any additional specific guidelines provided for working with scaffolding in areas with high levels of airborne contaminants. By following these guidelines, employers can minimize the risks associated with using steel tube couplers in scaffolding near areas with high levels of airborne contaminants or pollutants, ensuring the safety and well-being of workers.

- Q:Are steel tube couplers resistant to impact and shock loads?

- Yes, steel tube couplers are generally resistant to impact and shock loads. Steel is a strong and durable material that can withstand high levels of impact and shock without deformation or failure. The design and construction of steel tube couplers are specifically engineered to handle these types of loads. They are commonly used in various industries and applications where impact and shock loads are expected, such as construction, infrastructure, and automotive sectors. However, it is essential to ensure that the couplers are properly installed and maintained to maximize their resistance to impact and shock loads.

- Q:What are the maximum heights that can be achieved using steel tube couplers?

- The maximum heights that can be achieved using steel tube couplers depend on various factors such as the quality and strength of the steel, the diameter and thickness of the tubes, and the structural design of the overall system. However, steel tube couplers have been used in construction projects to achieve heights exceeding several hundred meters.

- Q:Are steel tube couplers compatible with scaffolding fall arrest systems?

- Yes, steel tube couplers are compatible with scaffolding fall arrest systems.

- Q:Can steel tube couplers be used with different types of scaffolding systems?

- Yes, steel tube couplers can be used with different types of scaffolding systems. Steel tube couplers are versatile and can be used to connect steel tubes of various diameters and lengths. They are commonly used in both traditional tube and coupler scaffolding systems as well as modular scaffolding systems. The couplers are designed to provide a secure and reliable connection between tubes, ensuring the stability and safety of the scaffolding structure. Therefore, steel tube couplers can be used with different types of scaffolding systems, making them a preferred choice for construction and industrial applications.

- Q:What are the common accessories or attachments used with steel tube couplers?

- Steel tube couplers can be enhanced with a variety of accessories and attachments, including: 1. Bolts and nuts: Utilized to securely fasten the couplers onto the steel tubes, ensuring a robust and dependable connection. 2. Gaskets: Frequently employed to create a watertight seal between the steel tubes and couplers, preventing any leakage or seepage. 3. Washers: Paired with bolts and nuts to evenly distribute the load and safeguard the steel tubes and couplers against damage. 4. Thread sealants: Applied on the threads of the couplers to prevent loosening or leakage, examples include Teflon tape or thread-locking adhesive. 5. Pipe caps or plugs: Used to seal off open ends of steel tubes when not in use, effectively preventing the entry of dirt, debris, or water. 6. Safety pins or clips: Often employed as an additional safety measure to secure the couplers and prevent accidental disconnection. 7. Paint or coatings: Coating the steel tube couplers with paint or protective coatings can enhance their durability, corrosion resistance, and aesthetic appeal. 8. Extension rods: Attachments that allow for the extension of the steel tubes, providing greater flexibility in construction or installation projects. 9. Lifting eyes or handles: These attachments make it easier to lift and position steel tubes, facilitating their handling on construction sites. 10. Identification tags or labels: Accessories that can be affixed to the couplers, providing important information such as part numbers, specifications, or project codes, which aids in inventory management and traceability.

- Q:Are steel tube couplers adjustable for different widths in scaffolding with limited access?

- No, steel tube couplers are not adjustable for different widths in scaffolding with limited access. Steel tube couplers are designed to connect two tubes of the same diameter and maintain a fixed connection between them. They provide a secure and rigid joint, ensuring the stability and safety of the scaffolding structure. However, if different widths or sizes of tubes need to be connected in scaffolding with limited access, alternative solutions such as adjustable scaffolding clamps or specialized connectors may be necessary. These solutions can provide the flexibility needed to accommodate different widths while still maintaining the required strength and stability in the scaffolding system.

- Q:Are steel tube couplers compatible with scaffolding accessories such as platforms and guardrails?

- Yes, steel tube couplers are compatible with scaffolding accessories such as platforms and guardrails. These couplers are designed to securely connect steel tubes together, allowing for the attachment of various scaffolding components.

- Q:Construction technology of fastener steel pipe scaffold safety technical specifications 2011 and 2001 how to download

- Wall insulation is an important part of home insulation work, divided into two kinds of external wall insulation and internal wall insulation, interior wall insulation works much smaller than the external wall insulation, there are four: 1

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products