Frame-Connected Scaffolding of Massive Power and Resouce Saving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

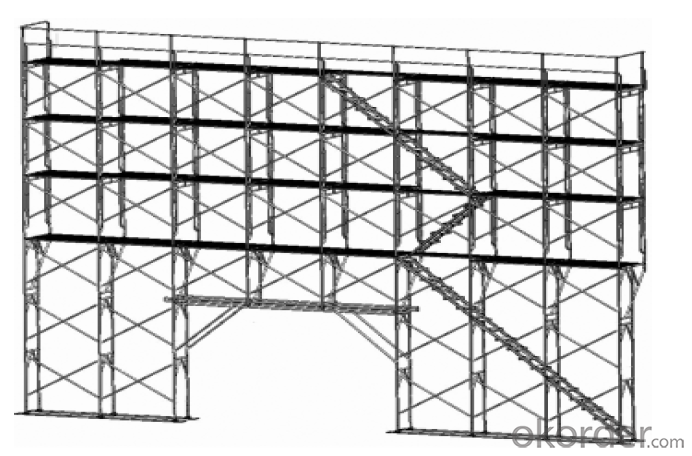

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

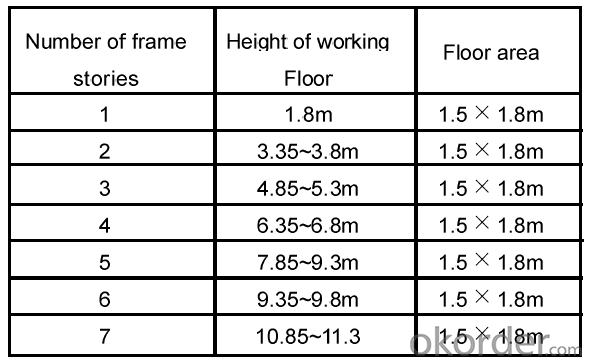

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How do steel tube couplers prevent tubes from slipping laterally?

- Steel tube couplers prevent tubes from slipping laterally by providing a secure connection between two tubes. These couplers are designed with a series of ridges, grooves, or teeth on the inside surface, which create a firm grip on the tubes when they are inserted. This grip ensures that the tubes remain in place and prevents any lateral movement. Additionally, steel tube couplers often incorporate locking mechanisms that further enhance the stability of the joint. These locking mechanisms can be in the form of bolts, nuts, or other fasteners that tighten the connection between the tubes, making it even more resistant to lateral slipping. Moreover, the material properties of steel also contribute to the prevention of lateral slipping. Steel is known for its high strength and rigidity, providing excellent resistance against lateral forces. When combined with the design features of the couplers, steel tubes are effectively secured in place, minimizing the risk of any lateral movement. Overall, the combination of the design features, locking mechanisms, and material properties of steel tube couplers work together to ensure that tubes remain securely connected and prevent any lateral slipping. This is crucial for applications where stability and structural integrity are essential, such as in construction, infrastructure, and various industrial settings.

- Q:can anyone tell me if these piercings hurt? i really like all of these piercing and plan to get them im not worried about the needle or anything like that its just the pain can you tell me how much these hurt compared to smiley or ear lobes. thanks :)

- septum-for me it did not hurt at all. the instant reaction though is the eyes water because of the area being sensitive. but i had no pain at all. i just inhaled deeply, and exhaled which is when the needle went through, and than they were like ok the needle is in. that needle went through like butta baby, because the piercer found what is commonly referred to as the soft or sweet spot. it was a little sore after, but that is common after most peircings. scaffold aka industrial-i do not have this done, but i have many friends who do. i heard the piercing itself does not hurt too much, but i heard afterwards it hurts like hell. it can become very sore and painful, especially because of the location, and how hair can hit it, or a shirt can catch on it, or you sleep on that side. i agree though, very cute. hand webbing i would imagine would not hurt at all. you probably would barely feel the hand webbing being pierced. i don't see the point in a hand webbing piercing, because i would think that could easily get in the way of many things. snake bite-i have the right side of my lip pierced, and to me that was my most painful piercing (i have left nostril, right eyebrow, septum, monroe, and right side of lip, and i had my labret before i got the monroe, but that has been retired) anywho..the right side of lip was the most painful for me. probably a 2 on a scale from 1-10. for me it was because my lips are thicker and fuller, and i have a lot of goodness for the needle to go through. but all in all, it depends on your pain tolerance level. for everyone it is different. i hope i helped! :)

- Q:Are steel tube couplers suitable for scaffolding projects in seismic zones?

- Yes, steel tube couplers are suitable for scaffolding projects in seismic zones. Steel tube couplers are designed to provide a secure and rigid connection between scaffolding tubes, ensuring stability and safety. They are capable of withstanding seismic forces and can be used effectively in areas prone to earthquakes.

- Q:Can steel tube couplers be used in scaffolding that requires specialized connections for signage or wayfinding systems?

- No, steel tube couplers cannot be used in scaffolding that requires specialized connections for signage or wayfinding systems. Specialized connections for signage or wayfinding systems typically require specific brackets or attachments, which cannot be achieved with steel tube couplers alone.

- Q:Are steel tube couplers compliant with safety regulations and standards?

- Steel tube couplers comply with safety regulations and standards, as they are designed and manufactured to meet specific safety requirements set by regulatory bodies like OSHA and ANSI. Rigorous testing and inspection guarantee their strength, durability, and ability to securely connect steel tubes. Used widely in construction and industrial applications, steel tube couplers join steel tubes together, providing structural strength and stability. They are engineered to withstand heavy loads, vibrations, and other external forces, ensuring the safety of workers and stability of structures. Moreover, galvanization or coating with corrosion-resistant materials protects steel tube couplers against rust and degradation, extending their lifespan and maintaining their integrity. Regular maintenance and inspections are also recommended to ensure compliance with safety regulations and standards. To summarize, steel tube couplers are compliant with safety regulations and standards, making them a dependable and secure option for connecting steel tubes in various applications.

- Q:Can steel tube couplers be used in scaffolding projects with limited timeframes?

- Yes, steel tube couplers can be used in scaffolding projects with limited timeframes. Steel tube couplers are quick and easy to install, allowing for efficient assembly and disassembly of scaffolding structures. Their strong and secure connections ensure the safety and stability of the scaffolding, making them a suitable choice for projects with tight schedules.

- Q:I wanted to hear about some people's experiences with these piercings, how much they hurt, tips of care, and things like that. I have heard that they put a numbing spray when doing an industrial (any comments on this?) Thanks for all of your advice and personal help. Anyone who is going to bag on piercings, why even bother? Thank you!

- Well I have some expierience in this department I currently have 19 piercings. As for your tongue my advice to you is to take 4 Midol (yes midol) every morning and nite for the first 4-5 days. Midol works as an antiinflamatory which will keep your tongue from swelling as it usually does. Also use listerine every time you eat or smoke for the first few days to keep it clean. This is all I did for mine and it was completely healed in 4 days and my tongue NEVER swelled up on me.

- Q:What are the common industry standards for the safe use of steel tube couplers in scaffolding?

- The common industry standards for the safe use of steel tube couplers in scaffolding can vary depending on the country or region. However, there are some widely recognized standards that provide guidelines for the safe use of steel tube couplers in scaffolding systems. One of the most prominent standards is the EN 74-1:2005 standard, issued by the European Committee for Standardization (CEN). This standard specifies the requirements for steel tube couplers used in scaffolding, including their design, materials, dimensions, and performance. It also provides instructions for the safe use and maintenance of these couplers. In the United States, the Occupational Safety and Health Administration (OSHA) sets regulations and standards for the safe use of scaffolding, including steel tube couplers. OSHA's scaffolding standards can be found in 29 CFR 1926 Subpart L, which outlines requirements for the design, construction, and use of scaffolds, including the use of couplers. Other countries may have their own specific standards for the safe use of steel tube couplers in scaffolding. For example, the British Standards Institution (BSI) has published a series of standards known as the BS 1139 series, which provide guidelines for the use of scaffolding, including couplers, in the UK. These standards generally emphasize the importance of using high-quality, properly designed and manufactured couplers that are suitable for the specific application and load requirements. They also highlight the need for proper inspection, maintenance, and training to ensure the safe use of steel tube couplers in scaffolding systems. It is crucial for individuals and companies involved in scaffolding operations to be aware of and comply with the applicable industry standards and regulations to ensure the safety of workers and the general public.

- Q:Can steel tube couplers be used with different types of scaffolding systems?

- Yes, steel tube couplers can be used with different types of scaffolding systems. Steel tube couplers are versatile and can be used to connect steel tubes of various diameters and lengths. They are commonly used in both traditional tube and coupler scaffolding systems as well as modular scaffolding systems. The couplers are designed to provide a secure and reliable connection between tubes, ensuring the stability and safety of the scaffolding structure. Therefore, steel tube couplers can be used with different types of scaffolding systems, making them a preferred choice for construction and industrial applications.

- Q:Are steel tube couplers suitable for supporting platforms or decking on scaffolding?

- Yes, steel tube couplers are suitable for supporting platforms or decking on scaffolding. Steel tube couplers are designed to connect steel tubes securely, providing a strong and reliable connection. They are commonly used in scaffolding systems to create a stable platform for workers to access elevated areas. Steel tube couplers are durable and can withstand heavy loads, making them ideal for supporting platforms or decking on scaffolding. Additionally, they are easy to install and can be adjusted to various angles and positions, allowing for flexibility in scaffolding design. Overall, steel tube couplers are a trusted and effective solution for supporting platforms or decking on scaffolding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frame-Connected Scaffolding of Massive Power and Resouce Saving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products