Flower Color 4'*8‘ feet Film Faced Plywood for Construction Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

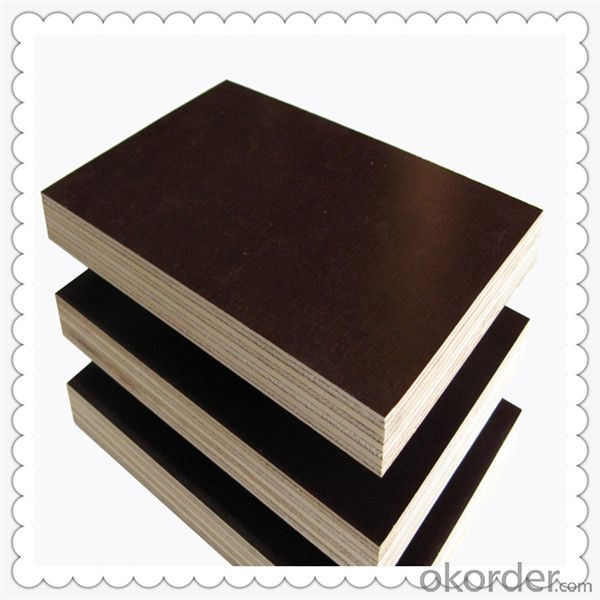

Brown Color 4*8 feet Poplar Core Film Faced Plywood for Construction Usage

Product Description:

· Type: Film Faced Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Plywood

· Use: outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

Film faced plywood is widely used in construction and building and vehicle industry for making transport equipment containers, loading platforms, truck and trailer floors and wagons.

This material is also used for making furniture such as chairs, tables, sofas, beds etc.

Film faced plywood can also be used to build sliding doors, advertising boards, play ground equipments, floors for sports arenas, smooth concrete casts, scaffolding, hoardings and fencings, packing and in internal & external design and panelling.

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q:The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q:Steel structure plant color steel sandwich panel roof design fire resistance 0.5H, need to apply fire retardant paint

- Steel structure color steel sandwich panel fire for 0.5 hours, if it is required to color steel fire board is 0.5 hours, then you must do fire paint, choose a thin fire paint more cost-effective, cheap. If it is required to color steel plate in the sandwich material to 0.5 hours, then you choose the appropriate sandwich material, such as rock wool made of sandwich materials.

- Q:What are the sandwich panels used in steel roofs? How much is the price?

- There are two kinds of steel panels used in steel roofs, one is called sandwich panels, that is, the factory has been the roof of the inner and outer color plate and the middle of the insulation layer composite; the other is called composite board , That is, the roof of the site at the site will be inside and outside the color plate and the middle of the insulation layer installed together. The advantage of the sandwich panel is because the factory has been compounded, so the site is quick and easy to install; the shortcomings are limited by the transport, the length is generally within 12 meters, the length of the slope is greater than the roof of the hidden water leakage. Because of its different insulation materials, one for the polystyrene sandwich panels, commonly known as foam board, the other for the polyurethane sandwich panels. Specifications are generally 50mm, 75mm, 100mm thick, the main use of the South 50mm thick board, the price according to the origin of color plate inside and outside the different, different thickness will be a difference to conventional 50mm thick, inside and outside the color plate for the OKorder Baosteel 0.5mm board For example, the unit price of about 65 yuan / m2, the land prices will be different Above the thickness of the board for each additional 15 yuan / m2. The advantages of composite panels due to the production in the field compound, you can ensure that the slope of a long slope, there is no leakage of hidden dangers; the disadvantage is that the installation of a little trouble. Thickness and price of the same as above

- Q:What is the polyurethane fireproof grade?

- Polyurethane sandwich panels are generally fire-resistant B2, can also reach the B1 level, belonging to the B-level self-extinguishing

- Q:Is not allowed to use foam sandwich color plate

- Hello! Now the state banned the use of foam sandwich color steel plate, also known as foam sandwich panels, because the foam sandwich board fire rating is poor, the state is prohibited. Now the market generally use rock wool color plate, which is used instead of rock wool composite board, fire rating up to A level. There are also some high-end customers with polyurethane color plates instead of using them, so the cost may be higher. Choose a most suitable for their own sandwich color plate can be used. After all, who is not the wind to the wind, the ability to do so

- Q:Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Self-tapping screw, the English name Self-tapping Screw is a metal or non-metallic materials in the pre-drilling hole in the self-drilling with a female thread with a threaded fastener. Self-tapping screws are used for connection between thin metal plates (steel plates, saw boards, etc.). When connecting, first thread the bottom of the connector, and then screw the tapping screw into the threaded bottom hole of the connected part. As the tapping screw thread surface has a high hardness (≥ 45HRC), can be connected to the threaded bottom hole in the internal thread, thus forming a connection.

- Q:Rock wool color steel sandwich panels how to choose

- Selection: Caigang rock wool sandwich board sub-machine board and manual plate two, Caigang sandwich panel is made of two layers of color coated steel plate for the surface layer, through the automatic compound molding machine, in the steel plate coated glue , At the same time on both sides of the board embedded in thin-walled channel, the pressure, blanking from the plate. 1, the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × 50, L × 1150 × 75, L × 1150 × 100 2, handmade rock wool color steel sandwich panel specifications: L × 985 × 50 3, color steel rock wool sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. 4, rock wool density: ≥ 120kg / m3 5, thermal conductivity: ≤ 0.046w / m.k 6, combustion performance: A-level (non-combustible) Caigang rock wool sandwich board for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding appropriate amount of binder, curing and made of processing. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on.

- Q:I am in OKorder because of procurement needs, would like to first understand the color steel factory in OKorder which manufacturers quality and cheap products! Worthy of lazy thanks!

- OKorder Bo Xing color steel company specializing in the production of rock wool sandwich panels, fire, waterproof performance is very good, the supply of a lot of large steel company, you are welcome to call us, absolutely high quality and cheap

- Q:I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flower Color 4'*8‘ feet Film Faced Plywood for Construction Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords