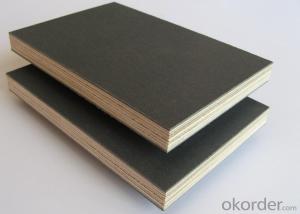

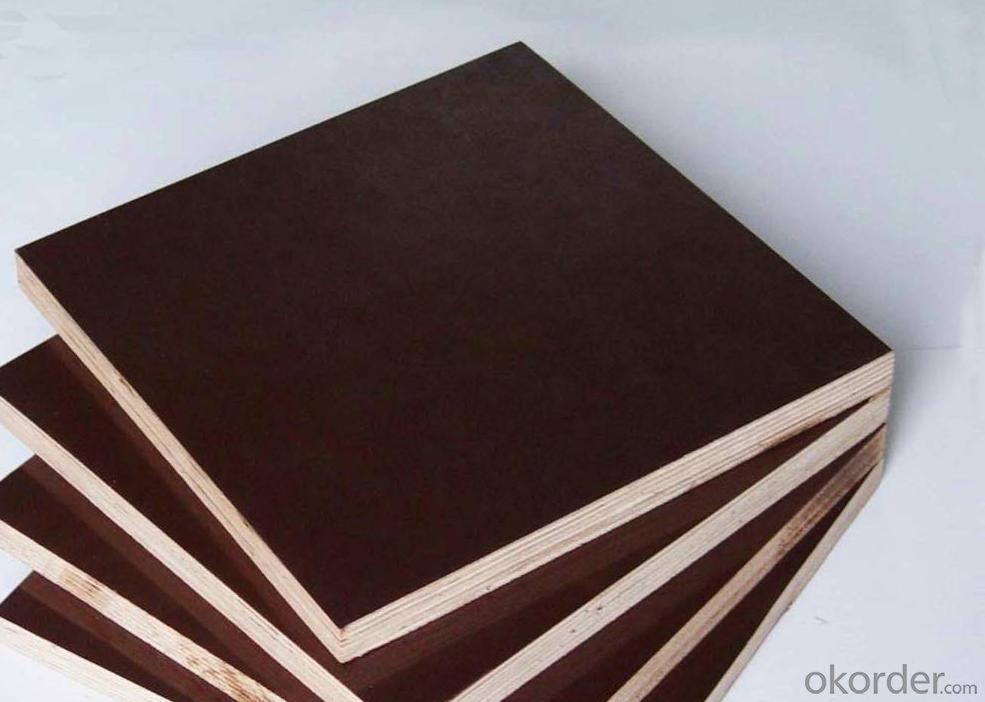

Film Faced Plywood for Construction with Combi Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

Features

1. Excellent performance of flame retardant;

2. High chemical stability and Anti-aging;

3. Excellent performance of bonding, coating and machining;

4. Mechanical properties meet the requirements of first-class product to national standard;

5. Non-toxic, non-polluting;

6. Non-corrosive metal;

7. Improved performance of Anti-Mildew;

8. Free formaldehyde content superior to class E1 of GB;

9. Low smoking and the high level of safety.

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

Packaging & Delivery

Packaging Detail: Inter packing: 0.20mm plastic bag;Outer packing: pallets are covered with plywood or carton

and then steel strips for strength

Delivery Detail: 15days after received 30%TT as deposit

commercial plywood

Specifications

1.commodity:commercial plywood.

2.size: 1220x2440mm, 915x2135mm.

3.thickness: 1.7-30mm.

4.glue: MR, E2, E1, E0, MEL, WBP.

Good quality commercial plywood for furniture use

Conventional data: | Size: | 1220mm*2440mm&1250mm*2500mm or as your demand | ||

1/8inch(2.7-3.6mm) | 3mm = 112sheets/cbm | |||

1/4inch(6-6.5mm) | 6mm = 56sheets/cbm | |||

Thickness: | 3/8inch(8.5-10.2mm) | 9mm = 37.33sheets/cbm | ||

(2.0—30mm) | 1/2inch(12-12.7mm) | 12mm = 28sheets/cbm | ||

5/8inch(15-16mm) | 15mm = 22.4sheets/cbm | |||

3/4inch(18-19mm) | 18mm = 18.66sheets/cbm | |||

Core: | poplar,hardwood,combi core etc | |||

Glue: | E0 , E1,E2,MR,WBP, MELAMINE | |||

Face/back: | okoume,bintangor,keruinging,poplar,pine,melamine paper etc | |||

thickness of faced: >= 0.45mm | ||||

Grade: | AAA first class | |||

Moisture: | <12%< span=""> | |||

Thickness tolerance: | (+/-)0.5mm | equal to and more than 12mm | ||

(+/-)0.3mm | less than 12mm | |||

Physical parameters: | density:>520—650G/cbm | |||

modulus of rupture: > 30Mpa | ||||

modulus of elasticity :>6000Mpa | ||||

Standards: | Plywood grading standard for USA order | |||

Export standard packing: | inner | pallet lined with 0.2mm plastic bag | ||

Outer | outside covered with carton then steel strip for strength, the bottom with regenerative wood pallet | |||

Quantity: | 20'GP | 8 Crates/12000kgs/21.43cbm | ||

40'GP | 16 Crates/24000kgs/42.87cbm | |||

40'HQ | 18-19 Crates/28500kgs/48.23cbm | |||

Delivery time: | 15 days after order confirmed | |||

Term of payment: | L/C at sight, T/T | |||

Capacity: | 5000 Cubic Meter / Month | |||

Certificate | CE,CARB,FSC,ISO9001,ISO14001 | |||

- Q:What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q:What are the plywood specifications?

- structure. The texture of the adjacent veneer should be at right angles; the center layer is symmetrical with respect to the center layer, and the thickness of the layers is the same;

- Q:Poisoning diagnosis and grading standards

- chronic benzene poisoning and blood cell involvement and the series and extent, and whether the evil is divided into light, medium and heavy three.

- Q:For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q:One of the commonly used materials for furniture is a wood-based panel

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression

- Q:Why is the plywood commonly used in the singular layer

- This is a good understanding of the regardless of the plywood and plywood they are for the sake of their each of them are vertical lines of the

- Q:Plywood in the material defects?

- discoloration discoloration Where the normal color of wood changes called color, can be divided into two kinds of chemical discoloration and fungal discoloration.

- Q:What plywood is now commonly used?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q:Solid wood and plywood which is better?

- the difference between selection: multi-layer solid wood flooring due to take into account the different species of "alternative heterosexual", so that the production process can fully balance the "internal stress"

- Q:The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Film Faced Plywood for Construction with Combi Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords