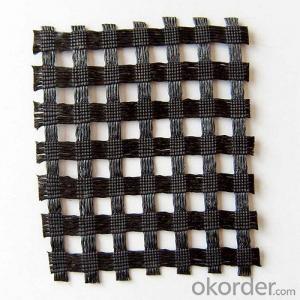

Fiberglass Polypropylene Geogrid Roadbed Reinforcement in Highway, Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How are geotextiles different from other types of geosynthetics?

- Geotextiles are a type of geosynthetic that are specifically designed to provide filtration, separation, and reinforcement functions in civil engineering applications. Unlike other types of geosynthetics such as geogrids or geomembranes, geotextiles are typically made from non-woven or woven fabrics, allowing them to have a higher permeability and flexibility. Geotextiles are primarily used to control soil erosion, improve drainage, and provide stability in various construction projects.

- Q:Are geotextiles cost-effective?

- Yes, geotextiles are considered cost-effective due to their durability, longevity, and ability to reduce construction and maintenance costs in various applications such as erosion control, soil stabilization, and drainage.

- Q:Can geotextiles be used in mining and landfill closure applications?

- Yes, geotextiles can be used in mining and landfill closure applications. Geotextiles are often used in these applications to provide soil stabilization, erosion control, and drainage solutions. They can help in preventing soil erosion, promoting vegetation growth, and improving overall environmental sustainability in these areas.

- Q:How are geotextiles recycled?

- Geotextiles are typically recycled through mechanical and thermal processes. Mechanical recycling involves shredding the used geotextiles into smaller pieces, which are then processed into new products such as erosion control blankets or construction materials. Thermal recycling, on the other hand, involves subjecting the geotextiles to high temperatures which break down the material into its constituent components for reuse in other applications. Both methods help reduce waste and promote sustainability in the geotextile industry.

- Q:Geotextile is what kind of material in the construction? Is it a hydroelectric material?

- Geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance.

- Q:Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles provide effective erosion control, drainage, and filtration properties, making them suitable for lining canals to prevent soil erosion and improve water flow.

- Q:What are the specifications for geotextiles used in geosynthetic tubes?

- Geotextiles used in geosynthetic tubes typically have specific specifications that vary depending on the specific application and project requirements. These specifications may include factors such as tensile strength, puncture resistance, permeability, UV resistance, and fabric weight. The specific specifications for geotextiles used in geosynthetic tubes should be determined based on the intended use and the engineering design of the project.

- Q:Geotextile use

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q:Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. They are commonly employed as a separation layer between subgrade soils and the ballast, helping to prevent the mixing of materials and providing stability. Geotextiles also aid in drainage, filtration, and erosion control, enhancing the overall performance and lifespan of railway tracks.

- Q:What are the advantages of using geotextiles in shoreline stabilization projects?

- Geotextiles offer several advantages in shoreline stabilization projects. Firstly, they provide effective erosion control by stabilizing soil and preventing it from being washed away by waves or currents. This helps maintain the integrity of the shoreline and prevents further erosion. Secondly, geotextiles act as a filter barrier, allowing water to pass through while trapping fine particles and preventing sedimentation. This helps maintain water quality and prevent the buildup of silt or pollutants. Additionally, geotextiles are highly durable and resistant to degradation, making them a cost-effective and long-lasting solution for shoreline stabilization.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Polypropylene Geogrid Roadbed Reinforcement in Highway, Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords