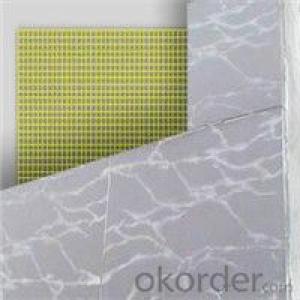

FIBERGLASS MESH TAPE 70G/M2 8*8/INCH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fiberglass wall mesh tape

1. Factory sell, good price

2. Tranship against anti-dumping is availabe

fiberglass wall mesh tape

fiberglass wall mesh tape description

Self Adhesive Fiberglass Mesh Tape is woven from C-fiberglass yarn, then coated with adhesive acrylic latex.

Save considerable time and eliminate one step of mudding when combining the self

adhesive mesh tape with a setting compound. The mesh tape’s open weave construction will allow moisture to evaporate evenly and much more quickly without the worry of bubbles and blistering when compared to paper tapes.

fiberglass wall mesh tape main qualities

• Very strong self-adhesive

• Sticks well in cold weather

• Will not absorb moisture

• Will not be affected by mold

• Fire resistant

• Will not tear

• Will not shrink

fiberglass wall mesh tape applications

• Seaming drywall joints

• Reinforce or repair wall cracks, plasterboard cracks, and cement board

fiberglass wall mesh tape technical data

Specification Declared | Yarn Tex- Warp | Yarn Tex- Weft | Adhesive acrylic latex coating | Tensile Strength(N/50mm) | |

70±5 g/m2, 9x9 Mesh | 66 Tex | 80 Tex | ≥30% | Warp: ≥500 N/50mm | Weft: ≥700 N/50mm |

60±5 g/m2, 8x8 Mesh | 66 Tex | 66 Tex | ≥30% | Warp: ≥500 N/50mm | Weft: ≥500 N/50mm |

50±5 g/m2, 9x9 Mesh | 66 Tex | 33 Tex | ≥30% | Warp: ≥500 N/50mm | Weft: ≥280 N/50mm |

- Q:How do you paste the mesh cloth on the back of the stone?

- Mesh cloth is used in home improvement projects for the grass-roots wall of the general name of anti cracking materials, mostly because of grid like name, also known as anti cracking cloth, anti cracking cloth mesh. The mesh cloth is usually made of glass fiber, and some people use cloth instead of anti cracking cloth in the actual construction. Wall cracking is a chronic disease of home improvement, so many people regard it as a magic weapon to prevent wall cracking. Different materials, new and old walls should be used.

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q:What are the fiberglass mesh fabric manufacturers?

- Glass fiber mesh cloth, also called fiberglass mesh, mesh cloth, heat insulation, it can be divided into standard type glass fiber cloth, glass fiber cloth reinforced, flame retardant glass fiber mesh and self-adhesive fiberglass mesh cloth four.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

- Q:Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q:Self-adhesive fiberglass mesh

- Self-adhesive mesh fabric is based on glass fiber mesh fabric as substrate, emulsion coating and self-adhesive coating. Therefore, it has good alkali resistance, softness and high tensile resistance at warp and weft direction. It can be widely used in EPS thermal insulation system.

- Q:What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

- Q:The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- The building often causes the perineum to warm up and contract cold and cause cracks. Reduce the service life, glass fiber mesh cloth can be the maximum restraint to reduce such adverse effects. The glass fiber mesh cloth is insulated and used in the outer part of the main structure so as to save indoor space. It is effective enough for indoor use

- Q:What harm does fiberglass mesh have to people?

- Inhalation of respiratory tract causing lung damage. Three

- Q:Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBERGLASS MESH TAPE 70G/M2 8*8/INCH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords