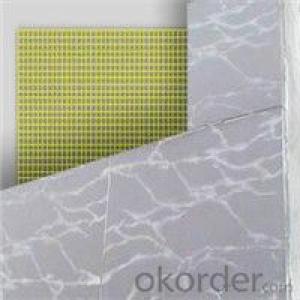

Fiberglass mesh cloth with high quality 70g 9*9/inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Fiberglass mesh :

1.ISO9001:2000 ,CE

2.mesh :4*5mm,5*5mm;

3.45g ~195g and 300g 1m*50m/roll

4.Clour: white, blue others.

Alkali-resistant fiberglass mesh

ISO, ETAG004, ITB, CE certificate

Superior quality and competitive price

Fiberglass Mesh is woven by fiberglass yarns, then alkaline-resistant latex coated. It owns great alkaline-resistant and high strength. As a perfect engineering material in construction, It is widely used to reinforce cement, stone, wall materials, roofing, gypsum and so on.

High Quality

Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after days NaoH test.

The fiberglass yarn is manufactured by ourselves. We have 60 unites Platinum Crucibles to produce glass fiber, It owns 20% more strength and beautiful surface than normal fiberglass yarn.

Package:

Each Fiberglass Mesh Roll is put into PVC bag or Shrink Bag, and then put into Carton or Pallet.

Fiberglass Mesh Specification:

Mesh size | Density | Width | Length per Roll | Colour |

(mm) | (gr/m2) | (mm) | (m) | |

2*2 | 30-600 | 100-2000 | 10-1000 | All colours |

2.5*2.5 | ||||

4*4 | ||||

5*5 | ||||

4*5 | ||||

5*6 | ||||

10*10 |

Specifications can be made as per customers requirements.

- Q:How do you paste the mesh cloth on the back of the stone?

- At the bottom of the stone board, besmear the resin glue, and then adhere to the fiber mesh cloth, forming tensile waterproof layer, but must not forget to brush in the side.

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistance refers to the performance of special glass fiber, while high alkali refers to the composition of glass fiber.Are two completely different concepts.

- Q:How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q:Slotted walls, seams, seams, tape, or anti mesh cloth?

- Very simple, you do not have to spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay. Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and you will not crack, affordable, the effect is very good, we give people a lot of friends after use, not see who split over ten years.

- Q:What's the price of fiberglass mesh?

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, tensile strength

- Q:Where is fiberglass mesh better?

- However, the import of fiberglass mesh cloth obviously higher prices. If more stringent cost control, can not consider the domestic crude Taishan glass fiber mesh cloth, glass fiber or wellav.

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- Acrylic emulsion less water, that is, high cost. It's cheap and good

- Q:What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q:What is the function of the wall cloth mesh?

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q:Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- This is absolutely no problem. Is the insurance, you, than it is to use some wall tiling grid cloth, ordinary mortar mortar is much better, but the cracking phenomenon is not so much that they...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass mesh cloth with high quality 70g 9*9/inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords