Fiberglass ceiling board acoustic ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass ceiling board acoustic ceiling

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

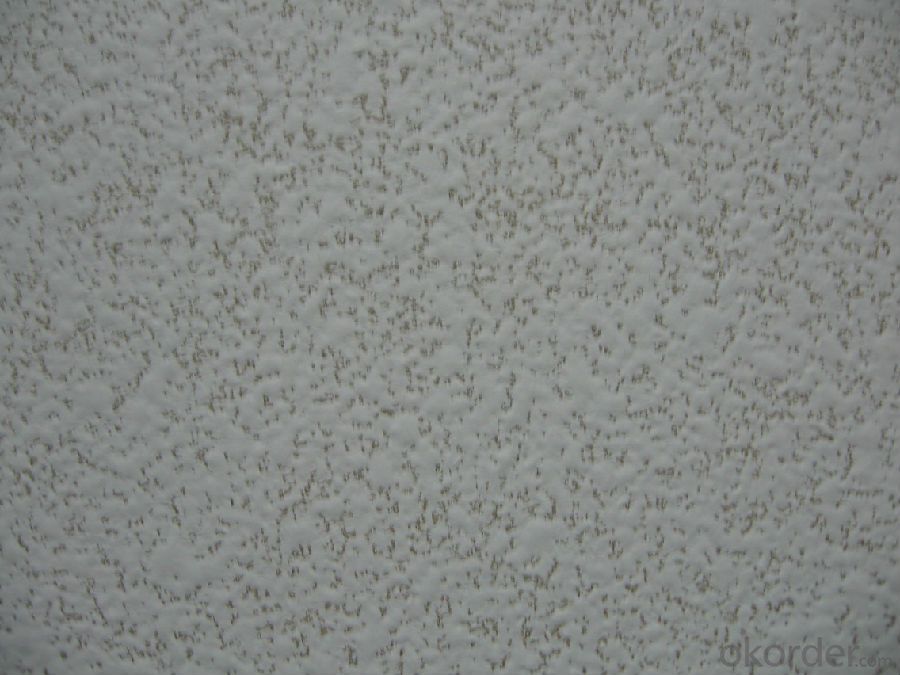

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

Black spray White spray

Mix Acoustic White painted

Fiberglass ceiling board acoustic ceiling

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

Fiberglass ceiling board acoustic ceiling

- Q:What is the space body?

- In the humid environment, can also be used single or double perforated plate for the sound absorption layer (to increase the absorption of low frequency, perforation rate is generally less than 5%), instead of porous materials. ④ hanging pieces. Such as metal lugs, hooks, bolts and so on. When used, the surface are placed in the sound field, is conducive to give full play to the sound absorption of the material. The effective sound absorption area of ??a single sound absorber is much larger than the geometric projection area, so if the projection area is calculated, the sound absorption coefficient can be greater than one. The characteristic is usually expressed by the effective sound absorption, which depends not only on the nature of the body itself but also on the interval between the absorbers but not in a linear proportion. So the best design should be the use of the least sound absorber unit, get as much as possible sound absorption effect. It is generally believed that if the plate-like sound absorber is used, the total area is 30% -40% of the flat top area of ??the room, the sound absorption efficiency can reach the best value and the economic effect is the best. Space absorber is mainly used to reduce the reverberation time in the hall and factory workshop and the sound level of the reverberation field. It has many advantages such as flexible design, simple installation, convenient installation and beautiful appearance. But it should also be noted that only in the original indoor sound absorption is very small, reverberation field is very strong circumstances, and the noise reduction effect is usually not more than 10dB, generally between 3-8dB, the best will not exceed 15dB The

- Q:What is the use of halogen powder

- English name: Magnesium chloride hexahydrate Chinese alias: halogen powder; flake magnesium chloride; magnesium chloride (casting); magnesium chloride (medicinal); magnesium chloride (edible); magnesium chloride (white) CAS RN .: 7791-18-6 Molecular formula: Cl2Mg. 6H2O Edit this paragraph morphological features Physical and chemical properties: pure character for the colorless monoclinic crystal. Industrial products are usually brown. Bitter and salty. Melting point 116 ~ 118 ℃ Relative density 1.569 Solubility soluble in water and ethanol. Uses: used for the production of magnesium metal, disinfectant, fire extinguishing agent, frozen salt water, but also for ceramics, paper, textile and other industrial magnesium chloride upstream raw materials Carnotite, octadecylamine, bromine, hydrochloric acid magnesium chloride downstream products Halogen, Magnesium hydroxide, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate, magnesium carbonate Magnesium, cleaning agent

- Q:What is good material for external wall insulation

- Now the external wall insulation are selected fire materials suggest you use a little better firewood rock wool board

- Q:But it's fiberglass and needs to be flexible for when it moves. I think actual mirrors will crack and be too heavy. What do I use for the mirrored effect?

- a fabric called mylar. The material most ballons are made from.

- Q:Specification for acceptance of glass cord sound - absorbing cotton

- "The latest switchgear testing test new technology, new equipment, new standards and product quality acceptance of the book"

- Q:The wall is a good brush or paste the wallpaper good ah that is more environmentally friendly if the brush which is also what brand of good paint

- Of course, is the choice of paint better, because the wallpaper is not durable, paste the wallpaper is not environmentally friendly glue, paint more durable and good care! Paint can choose Dulux

- Q:We just remodeled and now have a family room in our basement. This is right under our upstairs living room. All noise in the basement comes directly upstairs. There is duct work running across the basement ceiling to the floor vents in the living room. We have nothing on the basement ceiling right now. Any suggestions of how to reduce the sound coming up? And no, getting rid of our kids is not an option!

- Accoustical privacy is important in some shared spaces. There is sound attenuation batting which can be used between joists & around ducting even w/ a lay in type ceiling. Rigid fiber insulation is available for ducting as well. Regular fiberglass insulation is less expensive if you fill the entire space between joists. There is also sound damping drywall that can be used on ceiling but a double thickness of the regular stuff is less expensive will work ( but double the work) Have seen all of these remedies used on fmr job specified by accoustical engineers. Does not seem to be as much of a problem in residential type frame construction. Take one step at a time.. Might go for the duct wrap first & see how that goes then add batting then see how that goes then decide how you want to finish it off . The ducts are the main culprit but are the easiest part to fix. if needed , under floor batting will help kill noise from above as well as contain noise from below. Best regards

- Q:Do the glass fiber composite material be bad for the human body?

- The only drawback of fiberglass is that it can cause itching after contact with the human body.

- Q:My house from 2009 to 2017, upstairs two households turn water seepage, resulting in my house has watermark, and moldy black phenomenon, and now need to refurbish the processing, because the region is easy to resurgence in the winter, so need Heroes who help out, talk about my house need to brush a few layers, respectively, need to brush what paint, the more specific the better

- Smallpox and wall practices are similar: putty + latex paint Of course, for your home situation, you can use water putty 2 to 3 times, and then brush latex paint twice, latex paint to ask the business, it is best to combine a variety of effects. Latex paint a little more expensive, other materials are relatively cheap. Latex paint theory consumption of paint: 11-12 square meters / liter / single (dry film 30 microns) Due to the actual construction of the rough surface and dilution ratio is different, the amount of paint consumption is also different

- Q:My insulation was installed paper towards the roof.

- The paper (which is really a vapor proof barrier) should go toward the warm (in winter) side. The reason is to keep the insulation away from water vapor which will condense into water when it comes into contact with the cold, thus saturating the fibers and decreasing the insulation value. The batts in your ceiling were improperly installed if, in fact, the paper is actually a vapor barrier.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass ceiling board acoustic ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords