Fiberglass ceiling access panel not gypsum

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass ceiling access panel not gypsum

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

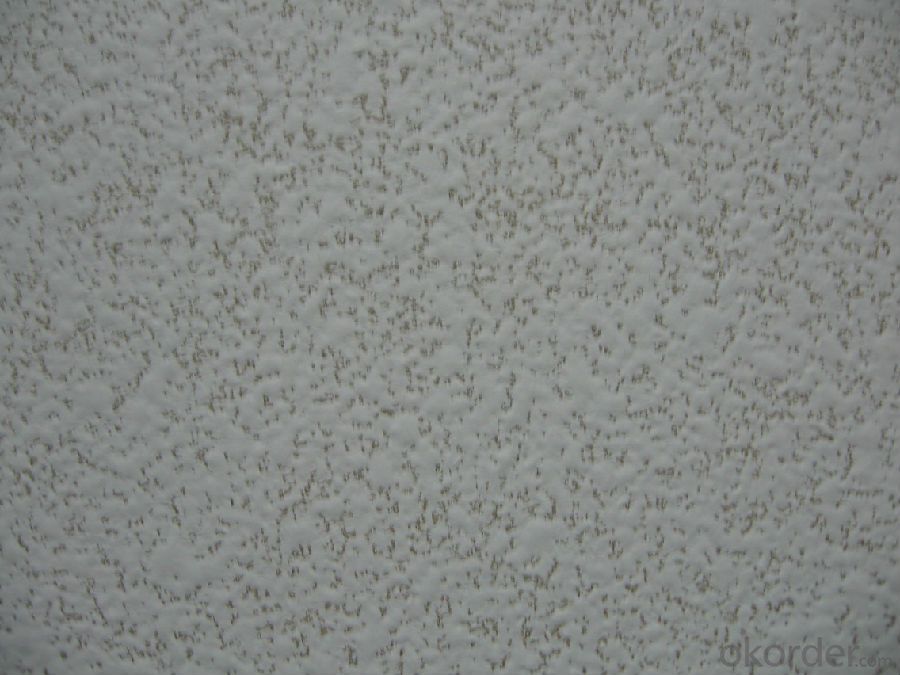

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

Black spray White spray

Mix Acoustic White painted

Fiberglass ceiling access panel not gypsum

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

Fiberglass ceiling access panel not gypsum

- Q:What is the best sound insulation effect?

- There is the kind of special sound-absorbing cotton ~ ~ KTV is the kind of ~

- Q:Fireproof fireproof glass fireproof shutter door What is it?

- You can be very intuitive to understand the fire resistance for the decorative parts, fire cut off, fire glass, fire shutter doors have in common, that is played an effective isolation; it is both functional, but also has the role of split space!

- Q:Renovation of living room wall with steel bricks

- That is too wasteful, and now is not popular. I think it is good with a big mud, both environmentally friendly and beautiful. The Also save money

- Q:also do the electronic noise makers get rid of the litte critters?

- NO to both parts of your question. You will be much better off if you find how they are getting in.

- Q:How to design a small living room look good.

- It is best to have a simple map. There are doors and windows of the size

- Q:What is the crystal structure of MgCl2

- Chemical Name: Magnesium Chloride [1] (MgCl2) Chemical Description: English name is magnesiumchloride. The chemical formula MgCl2 is composed of 74.54% chlorine and 25.48% magnesium, with a relative molecular mass of 95.21. Was colorless hexagonal crystals. Density 2.316-2.33 g / cm 3. Melting point 714 ° C. The boiling point of 1412 ℃. Usually contains six molecules of crystal water, that is, MgCl2 · 6H2O, easy deliquescence. For the monoclinic crystal, with or salty, there is a certain corrosive. Its density 1.569 g / cm 3, the melting point of 116-118 ° C, while decomposition. Soluble in water, heating and dehydration and hydrogen chloride from magnesium oxide. Use [2]: for the production of metal magnesium, disinfectant, frozen brine, ceramics, and used to fill the fabric, paper and so on. The solution and magnesium oxide mixed, can become hard wear-resistant magnesia cement. Method: from magnesium oxide or lime soil and hydrochloric acid role in the system. Seawater and salt brine are present in the presence of magnesium chloride. The shape of magnesium chloride [3]: generally in flake, block, crystal, particles and powder-based. Content of about 46% of magnesium chloride hexahydrate, 99% of anhydrous magnesium chloride. Magnesium chloride Chemical and physical properties: soluble in water and ethanol. Sensory indicators: white crystals, columnar or needle-like, bitter taste.

- Q:I was replacing a bathroom fan and the new bathroom fan is bigger than the old one. I took out the old one. Then I used a pencil and traced around the new fan. Then I used a reciprocating saw for the first time and got a little crazy with it. Now the hole is slightly too big and when I put the grill cover on the fan, I can see the hole. I'm not sure what to do now. I still got old pieces of the ceiling. Maybe I can do something with it?

- It sounds like when you put the fan in you can see holes around it. If that is correct then get some cardboard and wrap around the fan two or three times around the fan where it fits through the hole. So later when it is removed it give the correct gap around the fan fit to the hole.Now you should be able to secure the fan in place but not up tight to the roof, so you can still get plaster into the gap. Then get some plaster filler. you can get it from hardware store. And with a scraper that is used for plaster fill the gap. Let it dry. You then take the fan out and then remove the cardboard and discard. With the cardboard out their should be just the right amount of gap for the fan to fit back in snuggle and perfect. Use just enough cardboard as you think will do the job. The plaster also sticks to the card board and not the fan housing. You can also rap some Glad Wrap around the cardboard on the out side and it will pull away from the plaster easier when it is dry.Then sand, then you may need that repair with the fiber netting that sticks to it, to strengthen the around the hole. ( buy from hardware. just ask them and they will know. ) stick some of that on to strengthen it and put more plaster on. Let dry, sand and paint. If you google wall plastering repairs you should be able to get some demonstration on how to repair walls with holes so it will show you how to use the mesh to repair. It is not really very difficult. Good luck.

- Q:Our basement family room has an insulated ceiling but the bedrooms do not. One bedroom is below a bathroom and it gets very loud because of a water waste pipe. We have a storage room that has open access to the ceiling space. It would be about 20ft that we would have to push insulation into. This seems like it would be very hard with traditional roll insulation. It would be very easy to put some lengths of soundboard or xps or something in, but I don't know if it would achieve the desired effect. Thanks in advance.

- XPS - expanded polystyrene - would be a poor choice for sound insulation. Better than nothing, but not a great result for the money compared to some other choices. Fiberglass insulation does a surprisingly good job of reducing sound transmission. Add a ceiling to the joists above: suspended noise attenuation board - ask around at musical instrument stores for suggestions where to get that - can help a lot but it's pricier than other ceiling choices, so limit its use to where it's needed most: right around that pipe. If you're really sick of the noise, go nuts: Frame for a box of acoustic ceiling to go right around that entire pipe. Acoustic ceiling, also called drop ceiling tiles, again isn't everything it could be but it has the advantages of being cheap and easy to install. Make a trough that goes up against the floor above and box in that pipe. You might lose some tiles in the event of a future leak, but no biggie: the tiles are cheap. Now insulate around the box and under the floor above, same as you did elsewhere in the basement. Now install a dropped ceiling in the entire space. The noise from the pipe will probably still be audible, but it should be nothing like what it was.

- Q:My A\C and Heater have problems keeping up in Hot\cold weather. Its summer now (I live in the Stl area) and when its 90+ sunny my house will not get colder than 80 degrees A\C going non stop. The A\C is putting out anywhere from 59-62 degrees and from what I can tell is sized properly. In my ceiling is blown in insulation at about 4-5" sitting just above the 2x4s some places more some less. The vaulted ceiling being a little more at around 6" Is this enough? Is my problem the Heating\Cooling unit or is there not enough insulation?

- The minimum ceiling insulation should be R-30, with R-40 being the norm in the northern part of the U.S. The depth of insulation required to produce a R-30 depends on the type of insulation. Blown-in fiberglass will have about R-2.25 per inch, blown-in cellulose has about R-3.5 per inch and fiberglass batt has about R-3 per inch. In case you're not sure what type you have, fiberglass insulation looks like cotton candy, while cellulose looks likes ground-up newspaper. Batts are the best to install as there will be less airborne particles to breath, get in your eyes, etc. You just cut them to size and lay them across the ceiling joist so they seal any gaps caused by the ceiling joist, fans, light fixtures, etc.

- Q:Is it fiberglass, it looks like foam?

- Yes, it is fiberglass, intended to keep heat from the incandescent bulbs from overheating the ceiling. The foil is to reflect radiant heat for the same reason. Note that flourescent fixtures, which run much cooler, have neither of these heat barriers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass ceiling access panel not gypsum

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords