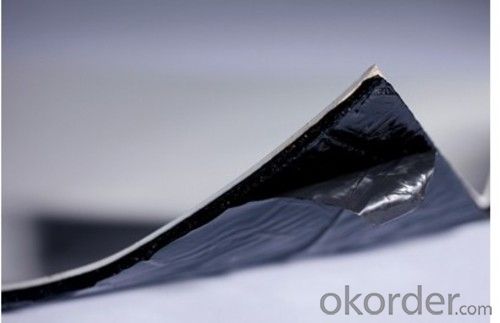

EPDM Waterproofing Rubber Membrane Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Features

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

Application

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be certified or approved by industry organizations?

- Indeed, industry organizations have the ability to certify or approve waterproofing membranes. There exist various industry organizations and standards bodies that assess and endorse building materials and products, including waterproofing membranes. These certifications or approvals serve as a guarantee that the membrane satisfies specific quality and performance standards established by the industry. Well-known industry organizations such as the International Organization for Standardization (ISO), Underwriters Laboratories (UL), and the American Society for Testing and Materials (ASTM) often grant certifications or approvals for waterproofing membranes. These certifications involve thorough testing and evaluation of the membrane's physical properties, such as its resistance to water penetration, durability, and compatibility with other construction materials. Certifications or approvals from industry organizations provide reassurance to consumers, architects, contractors, and building owners regarding the waterproofing membrane's thorough testing and alignment with recognized standards for quality and performance. They also facilitate compliance with building codes and may be obligatory for specific projects. It is always prudent to seek out waterproofing membranes that have received certification or approval from reputable industry organizations to ensure that you are utilizing a dependable and efficient product for your waterproofing requirements.

- Q:Can a waterproofing membrane be used on nickel surfaces?

- Indeed, nickel surfaces can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction and building ventures to safeguard surfaces against water damage and moisture infiltration. They serve as a barrier, preventing water from seeping through the surface and causing harm. Like any other metal surfaces, nickel surfaces can be vulnerable to corrosion and water-induced damage. By applying a waterproofing membrane, the nickel surface can be effectively shielded from water and moisture, thereby prolonging its lifespan and preserving its integrity. However, it is crucial to guarantee that the chosen waterproofing membrane is suitable for use on nickel surfaces. Different membranes may have distinct compatibility requirements, which is why it is advisable to consult the manufacturer or a professional for guidance on proper application and compatibility.

- Q:How does a waterproofing membrane handle settlement or movement of the substrate?

- A waterproofing membrane is designed to accommodate settlement or movement of the substrate by possessing flexibility and elasticity. It can stretch or contract to a certain extent without losing its integrity or allowing water penetration. This ability allows the membrane to adapt to any changes in the substrate, ensuring long-term waterproofing performance.

- Q:Does a waterproofing membrane provide any insulation against temperature fluctuations?

- Insulation against temperature fluctuations is not provided by a waterproofing membrane. The main purpose of a waterproofing membrane is to hinder the infiltration of water or moisture into the safeguarded region. It functions as a shield to maintain the structure's dryness and safeguard it from potential water harm. Although it might provide a certain level of thermal resistance based on its thickness and material characteristics, it is not crafted or intended to furnish insulation against temperature fluctuations. In construction, materials such as insulation foam or insulation boards are commonly employed to offer insulation.

- Q:Can waterproofing membranes be painted over?

- Yes, waterproofing membranes can be painted over. However, it is important to use a paint that is compatible with the membrane material and to ensure that the membrane is clean and dry before painting. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure proper adhesion and longevity of the painted surface.

- Q:What is sbs, app modified asphalt waterproofing membrane

- Compared to the use of SBS waterproofing membrane to use a larger range. But each has its own advantages and disadvantages, according to the local environment and the actual situation of the building in combination with the characteristics of two kinds of coil to choose materials. You have to compare the next, I can only tell you SBS waterproofing membrane prices than APP waterproofing membrane high.

- Q:Does a waterproofing membrane require any protective coatings or sealants?

- Yes, a waterproofing membrane generally requires some form of protective coatings or sealants to enhance its performance and durability. While the membrane itself provides a level of waterproofing, it may not be sufficient to withstand all environmental conditions or potential damage. Applying protective coatings or sealants on top of the membrane helps to create an additional barrier against water intrusion, UV radiation, mechanical stress, and chemical exposure. These coatings or sealants can also provide added flexibility, strength, and protection against wear and tear. It is essential to consult with a professional waterproofing specialist to determine the appropriate type of coating or sealant that suits the specific membrane and project requirements.

- Q:Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q:Can waterproofing membranes be used on metal roofs?

- Indeed, it is possible to utilize waterproofing membranes on metal roofs. When it comes to safeguarding and sealing roofs, including metal ones, waterproofing membranes are frequently favored. These membranes are specifically engineered to serve as a barrier against water infiltration, thereby safeguarding the roof's structure and preventing any potential leaks. They can be directly applied to the metal roof surface, creating an impervious seal that is resistant to moisture, UV rays, and other environmental elements. By implementing waterproofing membranes, the lifespan of metal roofs can be considerably prolonged, as they effectively prevent rust and corrosion, while also boosting energy efficiency by minimizing heat transfer. Consequently, applying waterproofing membranes on metal roofs represents a practical and successful approach to ensure both durability and longevity.

- Q:Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Food processing and pharmaceutical facilities can make use of a waterproofing membrane. These facilities often rely on waterproofing membranes to keep the surroundings dry and prevent water damage. By creating a barrier against moisture, these membranes ensure that leaks and water penetration are avoided. This becomes particularly crucial in environments where hygiene and cleanliness are of utmost importance, like food processing and pharmaceutical facilities. Furthermore, these waterproofing membranes can be applied to floors, walls, and ceilings, guaranteeing comprehensive protection. They are also commonly made from materials that resist chemicals and bacteria growth, making them even more suitable for use in sensitive environments. Ultimately, incorporating a waterproofing membrane in food processing or pharmaceutical facilities proves to be an effective method of maintaining a dry and safe environment for the production of high-quality products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Rubber Membrane Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords