EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet for EPDM Waterproof Membrane:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

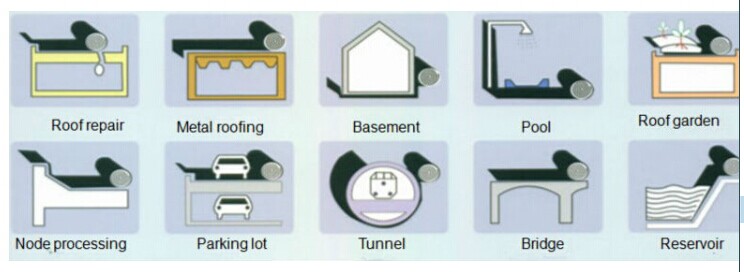

4. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

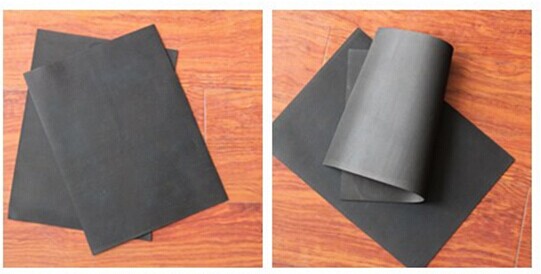

5. Some photos:

- Q:Can a waterproofing membrane be used on storage tanks?

- Indeed, storage tanks can benefit from the application of a waterproofing membrane. These specialized membranes serve as a barrier, preventing the infiltration of water or other liquids into the surface they are applied to. By employing such membranes, storage tanks are shielded from the detrimental effects of leaks, corrosion, and moisture-related damage. Numerous industries, including oil and gas, chemical, and water treatment, rely on waterproofing membranes to uphold the durability and longevity of their storage tanks. Furthermore, these membranes can be customized to meet specific requirements, such as resistance to chemicals, UV exposure, or high temperatures, thus making them well-suited for a diverse array of storage tank applications.

- Q:How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by being made of materials that are resistant to temperature changes and water infiltration. These membranes are typically composed of durable polymers such as polyurethane, polyethylene, or PVC, which have low permeability to water and can resist the expansion and contraction caused by freezing and thawing. During freeze-thaw cycles, water can enter small cracks and pores in a structure. When this water freezes, it expands, exerting pressure on the surrounding materials. This expansion can cause cracks to widen and weaken the structure, leading to water leakage and potential damage. However, a waterproofing membrane acts as a barrier, preventing water from penetrating the structure and reducing the potential for freeze-thaw damage. The membrane is installed on the exterior surface of the structure, forming a seamless and continuous layer that does not allow water to pass through. It adheres tightly to the surface and is flexible enough to accommodate the dimensional changes caused by temperature variations. Moreover, waterproofing membranes are often reinforced with other materials such as fabrics or meshes to enhance their strength and stability. These reinforcements further protect the membrane from damage during freeze-thaw cycles, ensuring its long-term effectiveness. In summary, a waterproofing membrane withstands freeze-thaw cycles by preventing water infiltration and resisting the expansion and contraction caused by freezing and thawing. Its composition, including durable polymers and reinforcements, makes it a reliable barrier against water penetration, reducing the risk of structural damage and maintaining the integrity of the protected surface.

- Q:Does a waterproofing membrane provide any insulation against temperature fluctuations?

- No, a waterproofing membrane does not provide any insulation against temperature fluctuations. Its primary function is to prevent water infiltration and protect the underlying structure from moisture damage.

- Q:Can a waterproofing membrane be used for water fountains or decorative features?

- Yes, a waterproofing membrane can be used for water fountains or decorative features. Waterproofing membranes are designed to provide a protective barrier against water penetration and can be applied to various surfaces, including those used in water fountains and decorative features. These membranes are typically made from materials such as rubber, bitumen, or liquid-applied coatings, which offer excellent waterproofing properties. By applying a waterproofing membrane, you can ensure that water does not seep into the underlying structure and cause damage. This is particularly important for water fountains and decorative features as they involve constant exposure to water. Additionally, waterproofing membranes can also help prevent leaks, cracks, and other potential issues that may arise from water exposure, thus prolonging the lifespan of the fountain or decorative feature.

- Q:Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Yes, a waterproofing membrane can be used for loading dock levelers and pit walls. Waterproofing membranes provide a protective barrier against moisture and can help prevent water damage and leakage in these areas.

- Q:Can a waterproofing membrane be used for podium decks or plaza areas?

- Yes, a waterproofing membrane can be used for podium decks or plaza areas. In fact, it is often recommended to use a waterproofing membrane in these areas to protect the underlying structure from water damage. Podium decks and plaza areas are typically exposed to the elements and can be prone to water infiltration. A waterproofing membrane acts as a barrier to prevent water from seeping into the underlying layers, ensuring the longevity and structural integrity of the deck or plaza. Additionally, a waterproofing membrane can also protect the space below the deck or plaza from water damage, such as basements or parking garages. It is important to choose a high-quality waterproofing membrane specifically designed for outdoor use and to follow the manufacturer's instructions for proper installation and maintenance.

- Q:Can a waterproofing membrane be used for tunnels and underground structures?

- Yes, a waterproofing membrane can be used for tunnels and underground structures. Waterproofing membranes are commonly used in construction to provide a barrier against water infiltration and protect structures from potential damage caused by water. In the case of tunnels and underground structures, where there is a higher risk of water ingress due to the surrounding soil and groundwater, waterproofing membranes are essential to ensure the integrity and longevity of the infrastructure. Waterproofing membranes for tunnels and underground structures are specifically designed to withstand the unique challenges posed by these environments. They are typically made of durable and flexible materials such as bitumen, PVC, or EPDM, which can effectively resist water pressure and provide long-lasting protection. Additionally, these membranes are often reinforced with various layers or fabrics to enhance their strength and resistance to puncture or tear. The application of waterproofing membranes in tunnels and underground structures involves a meticulous process. The surfaces that need to be waterproofed, such as the walls and floors, are thoroughly cleaned and prepared to ensure proper adhesion of the membrane. The membrane is then applied in multiple layers, ensuring complete coverage and a seamless seal. Special attention is given to critical areas such as joints, corners, and penetrations to prevent any potential weak points. By using a waterproofing membrane, tunnels and underground structures can be effectively protected from water intrusion, groundwater pressure, and potential damage caused by moisture. This helps to maintain the structural integrity of the infrastructure, prevent water-related problems such as leaks, corrosion, or deterioration, and ensure the safety and functionality of the tunnel or underground facility.

- Q:Can a waterproofing membrane be used on tunnels with ventilation systems?

- Yes, a waterproofing membrane can be used on tunnels with ventilation systems. In fact, it is highly recommended to use waterproofing membranes in such tunnels to prevent water infiltration and potential damage to the tunnel structure or the ventilation system. The waterproofing membrane will create a barrier that prevents water from seeping into the tunnel, ensuring its integrity and protecting the ventilation system from water-related issues such as corrosion or moisture build-up. Additionally, using a waterproofing membrane can help maintain the efficiency and effectiveness of the ventilation system by preventing moisture or water vapor from entering the tunnel and potentially causing condensation or mold growth. Overall, using a waterproofing membrane in tunnels with ventilation systems is a crucial step in ensuring the long-term durability and functionality of both the tunnel and its associated ventilation system.

- Q:Can a waterproofing membrane be used on terrazzo surfaces?

- Yes, a waterproofing membrane can be used on terrazzo surfaces. Terrazzo is a durable and long-lasting material, but it is porous and can absorb water if left untreated. Applying a waterproofing membrane helps protect the terrazzo surface from moisture damage, preventing water penetration and potential issues such as staining, cracking, or mold growth.

- Q:Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane typically requires special cleaning and maintenance procedures to ensure its effectiveness and longevity. Regular inspections, cleaning off debris, and addressing any damage or wear are essential to prevent leaks or deterioration. Additionally, specific cleaning products and techniques may be recommended by the manufacturer or installer to maintain the membrane's performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords