Easy Assemble Fiberglass Grate Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

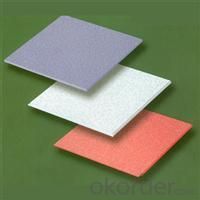

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q:The kitchen of the flue was decorated to open a great! How to seal this mouth? What materials?

- Smoke mouth processing methods: 1, the use of public flues, must be equipped with a smoke check valve, or you will regret later, the smoke comes with the check valve, the effect is not good, no matter how much the brand are the same. A separate pipe out of the wall, their own row, you can not consider. 2, the kitchen flue mouth and the connection of the pipe, must be sealed and handled, or no matter how good the smoke check valve can not completely block the taste of others cooking at home. Hobbies other people to cook the fragrance of the students except. 3, the kitchen flue mouth opening position must be high, for the smoke pipe into the ceiling, in order to save valuable space hanging cabinet.

- Q:Now a lot of people with rock wool ceiling, rock wool ceiling what is special?

- Excellent sound grams of products to ensure that no deformation for 15 years fall. Excellent quality grams of ceiling using high-quality volcanic stone, through the European advanced production equipment and technology made,

- Q:Renovation of living room wall with steel bricks

- That is too wasteful, and now is not popular. I think it is good with a big mud, both environmentally friendly and beautiful. The Also save money

- Q:The house is a brick house, the kind of red brick house in the past, the wall looks quite thick, but still no noise at night neighbors next night to sleep, his family moved to hear the sound of things, often insomnia , And neighbors greeted, but inevitably there are voices, depressed dead, I sleep light, ask no sound to sleep, to death ... ... my family and his home are wooden floor, I do not know this sound Where did you wear the wall or the floor?

- Install the sound board

- Q:What is good material for external wall insulation

- Foam cement insulation materials Foam cement, the earliest German material used in China was introduced around 1980. Through the foaming system of the foaming machine, the foaming agent is fully mechanically foamed and the foam is mixed with the cement slurry and then subjected to in-situ construction or mold forming through a foaming machine pumping system, The formation of a large number of closed pores containing a new type of lightweight thermal insulation materials. It is a bubble-like insulation material, highlighting the characteristics of the concrete is formed inside the closed foam hole, so that lightweight concrete and insulation insulation.

- Q:I have hanged the drywalls on both the ceiling and walls. My questions is how should I tape the joints between the ceiling and walls? Should I use a regular paper tape, a fiberglass mesh or a paper corner bead (inside corner)?

- there is a certain art to taping sheetrock, but don't be afraid anyone can do it 1. make sure you mix your spackle well, use a drill and paddle for the first coat, apply an ample coat and then tape, don't get too far ahead of your abilities. the second coat should feather the first coat outward, and when doing corners do one inside at a time after the tape coat.Just remember its easier taking it of when its wet than dry. Also mix some dish washing liquid for the second coat, this will prevent bubling.

- Q:Home improvement waterproofing process and what is the standard

- 1, in preparation for acceptance of the room door to start 15 cm high retaining wall; 2, in the room into 10 cm deep water, at the same time to do the height of the water mark; 3,24 hours after the observation of whether the height of the water surface has changed, but also check the same location downstairs room ceiling whether the phenomenon of water seepage; 4, if there is no such phenomenon, that can be considered waterproofing construction acceptance; the other hand, if the inspection found that the phenomenon can be considered waterproof construction failed. If the acceptance of substandard, waterproofing works must be redone the whole, re-acceptance; for lightweight wall waterproofing construction acceptance, should take the water test, that is, the use of water pipes in the waterproof paint on the wall from top to bottom Intermittent spray 3 minutes, 4 hours after the other side of the wall to observe whether there will be infiltration phenomenon, if there is no penetration phenomenon can be considered waterproof wall construction acceptance.

- Q:What is the specific waterproofing of the bathroom? How much is the height of the wall As well as craftsmanship?

- Polyurethane waterproof coating general approach is as follows: 1, the ground to the direction of the ground to find slope, cement mortar or bean concrete can be, but the surface to be flat. Near the door slope is small, the gap near the slope, according to the specific situation to master. 2, the pipeline to wear the floor of the root, to strengthen the waterproof. Tube root construction seal seal, cement smoothing foot protection, brush waterproof coating when the paste from the wire to strengthen the layer 1 to 2 layers. The same measures around the floor drain. 3, the wall to deal with clean plain light without floating ash, small particles, wall ground junction to wipe the original angle or slope angle. Brush waterproof coating when the glass cloth to strengthen the layer 1 to 2 layers. 4, the total thickness of polyurethane waterproof coating requires more than 1.5 mm. Can not rely on the number of decisions. Root, corner reinforcement layer at the first brush, room temperature 4h dry, and then a large area of ??brushing, Tu scraping. There is no leakage scraping, bubbling phenomenon. Large area brushing 24h curing after brushing the next layer. 5, first brushing the facade after brushing the plane, the next brushing direction and the vertical again. The last time the film semi-curing, throwing coarse sand particles, easy to combine with the cement mortar in the future. 6, the ground waterproof layer should be painted out of the bathroom door outside the 300 wide. Waterproof surface waterproof layer should be higher than the ground 200, a shower bathroom wall waterproof layer should be higher than the ground 1800 (L8 recommended full wall waterproof).

- Q:Hi, about 2 weeks ago I was in my ex boyfriend's attic (with his permission! lol) and he noticed a crack, which turned into a hole when I slipped and almost fell through into the bedroom! If you lie in bed you can now see right through to the attic; while it could be considered a design feature, my ex isn't keen on it :-) It's not very big, probably only 1.5ft square if that but obviously the plaster is missing, one of the lathes (think that's what they're called; the thin pieces of wood just behind the plaster) is broken in half and poking throught he hole and little bits of the fibreglass indsulation are falling down. My ex told his landlord who said it would cost ?150 to repair the damage, but I'm convinced my ex could do it himself...but how? Any ideas? I have been offered a large piece of plasterboard, could he use this in any way and would he have to enlarge the hole to replace the entire lathe? How does he replaster...etc - help please!

- You only need to replace the lath with anything which will act as a backing for the spack filler which you will need to get from a hardware store or even your local supermarket if your lucky. A suitable replacement will hold your bit of plasterboard, which you have cut to fill the hole as best as possible, and must be able to cope with the environment in the attic, ie not rot. Then fill the crack around the edge with spack filler (white stuff, like plaster, many different types) Then when thet repair has set fill over the plaster board to make it level with the roof, any white spack filler type material. Dry sand and paint to match celing (that is the hard part). Good luck.

- Q:How to conduct a comprehensive review of self-leveling

- Construction technology 1. Check the ground humidity, confirm the ground dry; check the ground flatness, confirm the ground level; check the ground hardness, the ground should be no cracks. 2. Thoroughly clean the ground, remove all kinds of dirt on the ground, such as paint, oil and paint and so on. Fully polished the ground. 3. completely suck the dust. 4. The interface agent with a foam roller coating, 1: 1 watered, the amount per square meter is about 100-150 grams. 5. After the application of the interface agent, wait for 1-3 hours to maintain good ventilation, so that it is completely dry. And then self-leveling construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Easy Assemble Fiberglass Grate Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords