Ductile Iron Pipe Fittings ISO2531/EN545 DN1600 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Fittings Description :

Pipe fittings confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.Pipe fittings ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633 we can do third party inspection according to customer's request.

2.Main Features of the Ductile Iron Pipe Fittings:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

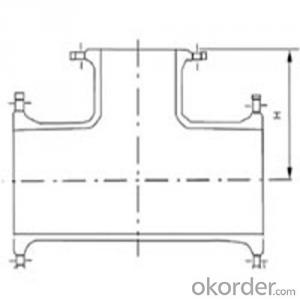

3.Ductile Iron Pipe Fittings Images:

4.Ductile Iron Pipe Fittings Specification:

Internal lining: ductile iron pipe fittings shall have an internal cement mortar lining in acc with ISO4179.

External coating: ductile iron pipe fittings shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: ductile iron pipes from DN100 to DN300 be bundled with steel belts

5.FAQ:

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes fittings, improving resistance to erosion of the sewage components.Q: Why would you choose ductile iron pipe fittings rather than other pipe fittings materials?

A:The reasons are obvious for that not only ductile iron pipe fittings possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

- Q:how are the Titleist AP2 irons? Do they feel good? Pros. Cons.?

- They are definitely great irons. Simply put the AP2 has the weight of a game improvement club with a players forged head. The design promotes a higher ball flight but that can be altered depending on what shaft combination you desire. The club is not as intimidating as a blade or players club. The topline is larger and the tungsten cavity slot back provides forgiveness on most mishits. Unlike a blade most mishits with the AP2 stay on the target line with a slight loss in distance.

- Q:So I am trying to increase my iron levels as I have to give blood soon. Well I picked up an iron supplement and I took one. Well I just realized that it has 65 mg of iron in one pill. Why would they sell these if toxicity is over 50mg. Am I gonna be okay?

- It is great that you are giving blood. However, unless you are suffering from iron deficiency anemia, no amount of iron is going to increase your hemoglobin count. You could take iron after the event, to speed up recovery, but most people do not have a problem in getting back to a normal level. 65mg of elemental iron ( usually in salt of iron about 300mg ) is the treatment dose for simple anemia. Toxic levels for an adult male start at about 700mg of elemental iron daily. If your hemoglobin level is normal, you need no more than 20mg daily for good health. Plenty of foods contain iron including green vegetables and liver

- Q:my iron level has been at this my whole pregnancy and I have a really hard time taking Iron pills so I am doing the foods and cereals with lots of Iron did any of you Lady‘s go into labor with low iron how was your experience was every thing ok ??

- im 32weeks pregnant and i also have low iron, i been taking iron pills for 3weeks now. How come your having a hard time taking them? Im a Vegetarian so i dont like meat, but red meat is good for you if you have low iron. Wheat bread or white bread, rice, beans, peanut butter, cereal, soy milk and almond milk, green vegetables, veggie burgers, and mushrooms have iron. One bowl of cereal with soy milk or almond milk has 55-70% of you daily Iron needs, depending on how much milk and cereal you use. A peanut butter and jelly sandwich has 12% of your daily Iron needs. Green, leafy vegetables have 10-25% of your daily iron needs, depending on the vegetable. Post raisin bran is very high in iron. I recently bought a box, and it has 60% of your daily iron needs. But you could also buy a cheap Malt-o-meal bag of cereal, and it will usually have 30-50% of your daily iron requirements.

- Q:You have a spool of wire, a glass rod an iron rod and an aluminium rod. Which rod should you use to make an electormagnet to pick up steel objects? Explain

- It is fairly easy to build an electromagnet. All you need to do is wrap some insulated copper wire around an iron core. If you attach a battery to the wire, an electric current will begin to flow and the iron core will become magnetized. When the battery is disconnected, the iron core will lose its magnetism.

- Q:How much iron should we take during pregnancy? How many mg?I am in Asia right now, I take my prenatal vitamin daily, but my doctor in Asia gave me more iron for 2 mg. a day.People say that everyone here takes more iron, so I am worried if I take too much.

- How Much Iron Should You Get During Your Pregnancy? You needed about 15mg of iron per day pre-conception, which is a fair amount. Many women who aren't pregnant do not even reach the RDA each day. Now that you are pregnant you will need almost twice the amount of iron per day.

- Q:1. Can they use rusted iron (since it is in the water)2. How does the iron keep from sinking since they live at the surface

- Phytoplankton require a variety of essential nutrients, including iron, to fix carbon dioxide and fuel ocean food webs, but the oxidized form of iron, Fe(III), that prevails in the ocean is only sparingly soluble in oxygenated seawater. The solubility of iron is enhanced through chelation with organic ligands, and nearly all of the dissolved iron in seawater is bound to natural ligands. More details in link.

- Q:Ar these nice irons for 13 handicapper

- WELL IT ALL DEPENDS ON WHAT YOU WANT. YOUR GAME WILL NOT IMPROVE THAT MUCH WITH THE EQUIPMENT YOU USE TO AN EXTENT. REMEMBER THAT GOLF CLUBS ARE PROBABLY THE WORST INVESTMENT YOU CAN MAKE. I SUGGEST THAT YOU SELECT IRONS THAT YOUR COMFORTABLE WITH. DON'T SELECT THE WRONG LOFT OR SHAFTS BECAUSE YOU WILL ACTUALLY BE HURTING YOUR GAME NOT HELPING IT. CONSULT WITH SOMEONE WHO KNOWS WHAT THEY ARE DOING LIKE YOUR HEAD PROFESSIONAL. DON'T GO WITH THE REP OR A SALES GUY YOU MAYBE DISAPPOINTED AND ACTUALLY PURCHASE THE WRONG CLUBS. GOOD LUCK.

- Q:what are iron filings? what characteristics does iron filings have? is it a metal because it is attracted to magnets?

- Iron filings are very small pieces of iron that look like a dark powder. They are very often used in science demonstrations to show the direction of a magnetic field. Since iron is a ferromagnetic material, a magnetic field induces each particle to become a tiny bar magnet. The south pole of each particle then attracts the north poles of its neighbours, and this process repeated over a wide area creates chains of filings parallel to the direction of the magnetic field.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe Fittings ISO2531/EN545 DN1600 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords