CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

Products Introduction

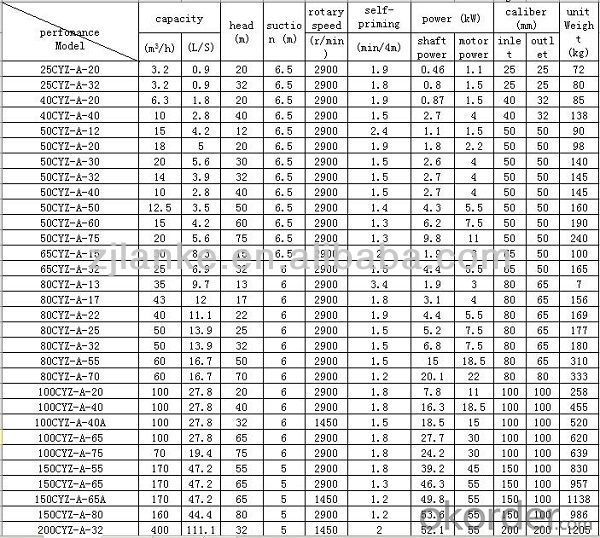

Main datas:

Capacity( flow rate) : 3.2-550 m3/h

Head : 12-80 m

Speed: 1450 / 2900 rpm

Power: 0.75 ~ 132 hp

Suction:4-5.5 m

Advantage :

1. Big pump body pass 60% of the inlet&outler solid ,

2. High suction head 4-5.5 m,have sewage

3. Used for oil and Marine, Copper impeller

4. OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

5.CE ,TUV .ISO .CO

Name: Lanco brand CYZ-A self priming Centrifugal Electric oil pump 24 volt

Summarize

CYZ-A series fuel pump is a new modified centrifugal pump which is

developed on the basis of absorbing domestic and overseas advanced technology of the same

product and combining many years design and manufacturing experience of our company.

1) Detailed instructions

Lanco brand cyz Series Siemens Electric Oil Pump

1.Flow capacity:3.2-500m3/h

2.Head: 12-80m Ciemens oil pump

3.Rotary speed: 2900rmp

4.Power: 0.75-110kw

5.Suction lift: 5-6.5m

2). Application Area

1. fuel pump is widely used totransport gasoline,kerosene,diesel oil ,oil for warehouse ,oil station ,oil tanker,dock,tank truck,airdrome ect.

2.Used in chemical industry ,pharmaceutics, brew-age,electroplate ,printing and dyeing,papermaking, electric power ,mine etc.

3. Suitable for Marine cargo pump, bilge pump, fire pump, ballast pump nd cooling water circulation machine

4. Applicable to the oil industry, oil depot, oil tank truck land .

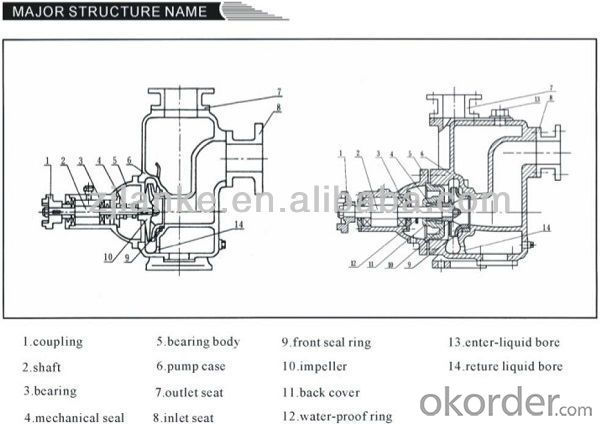

3) Oil pump characteristic 1.Simple structure,convenient operation and maintenance,stable working,hagh efficiency,

long life,good self-priming etc are its main characteristic.

2.It can also be used as pump for cleaning off cabin in tanker and water supply of ship with

high efficiency.

3.It's made up of material of high quality.Seal is hard alloy mechanical seal.So the pumps

have a long life.

4.It need not security valve in output pipeline and no bottom valve in suction valve

insuction pipeline,so it perdigests pipeline system and improves working condition.

4) Operating Condition

1.Medium temperature:-20°C~80°C,

2.Viscidity≤100centipoise

3.Particals consistency can reach 30%.

5) Mounting Configuration

| ♦ Frame Mounted |

| ♦ Base Mounted Electric Driven |

| ♦ Engine Driven SAE Mounted |

| ♦ Engine Driven Skid or Trailer Packages |

| ♦ Horizontal or Vertical V-Belt Driven |

5)Parameter

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q:What is the pump delivery? What's the difference between years and years?

- First of all, as a student majoring in insurance, I strongly condemn the first floor of ignoring practice and trampling on real knowledge!!The insurance industry criticized a lot, but it is required for many people, we should face and try to maintain the healthy development of the industry, the first floor of the insurance you have not done, have no contact with the insurance, insurance, not to dictate the nonsense, more should not be here misleading!

- Q:What is the dry running protector of screw pump? What's the principle and function? Thank you

- The utility model relates to a screw pump dry running protector, which is used for protecting the stator and the rotor of the screw pump from being transported by air

- Q:Working principle and structure of external gear pump

- The principle of the gear pump, gear pump structure consists of two gear mesh together with each other, and composed of pumps known as gear pumps. It relies on the gear teeth meshing space change in volume to transport the liquid, it belongs to the rotary pump, also can be considered as a volume pump. There are many kinds of gear pumps. According to the meshing mode, it can be divided into external gear pump and internal gear pump. According to the tooth shape of gear, it can be divided into positive gear pump, helical gear pump and herringbone gear pump.

- Q:What does the pump mortar do?

- 1: 2 cement mortar or cement mortar with the same proportion of other components except coarse aggregate in the concrete, the pump piston and the inner wall of the pipeline are fully lubricated, and a layer of lubricating film is formed

- Q:How many pumps does the 80cm tank use?

- For example, you are 80 cm tank, assuming you are 40 cm wide, the water surface is also 40 cm, then the final count by 80X40X40=128000 cubic centimeter, that is, 128000 ml.

- Q:How to install, operate and maintain the pipeline booster pump?

- The motor coil is provided with a safety protector, and when the pump is out of order or the water is not pumped, the motor can automatically break down when the temperature of the motor exceeds the prescribed value, and the motor can automatically resume operation after the temperature rise of the motor is decreased. The booster pump motor is a capacitor running type motor. When the pump leaves the factory, the rotation direction has been adjusted. If you need to replace the capacitor or re connect, press the arrow direction on the pump body to mark the connection. To ensure safety, use the three - core safety socket with ground wire.

- Q:What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q:What is the name of the day pump and ground pump? Specific introduction

- Day pumpDay pump is called "day pump", the main reason is that it can deliver concrete to a certain height, make up for other concrete pump transportation shortage. Compared with other concrete pumps, the pump has its own boom, and the concrete can be transported without the use of artificial cloth. It is very convenient for use. At present, China's longest boom pump is 101 meters, which means that 101 meters under the floor can be completed with the help of day pump concrete delivery. In addition, the pump is equipped with a chassis, so compared with the ground pump, it can walk independently, moving very convenient, you can quickly move from one site to another location.

- Q:If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- If the fish tank is made of metal, the fish tank is grounded or connected to the zero line, and then the fire line is put into the water, then your fish will be electrocuted immediately. Go back to the submersible pump, submersible pump line and the zero line very close, even if the firing line and the zero line at the same time the leakage occurs, fish could not swim between the firing line and the zero line, so the tank submersible pump leakage will cause the following hazards: 1, electric shock. 2, submersible pump short circuit. 3, the submersible pump serious fever, resulting in water temperature tank.

- Q:What are the conditions required for hydraulic pumps to complete oil absorption and compression?

- 2, the change of working volume is periodic, and in each cycle, the oil absorption process is changed from small to big, and the process of oil pressure is changed from large to small;3, suction oil cavity must be separated from each other without interference.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords