Corundum Mullite Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

Corundum brick primarily used for the key parts of the industrial furnace of steel,metallurgica,electronics,petrochemical,chemical fertilizers,non-ferrous metals,refractorty material etc high temperature industrial kiln furnace,such as glass furnace,cement kiln, heaters molten steel ladle,metallurgical furnaces for nonferrous metals and furnaces for chemical engineering industries.

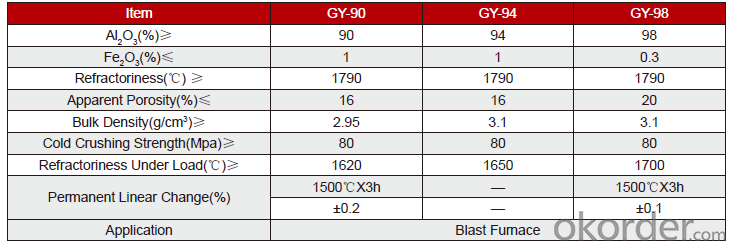

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q:What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q:How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q:What kind of refractory material will be used in the glass kiln?

- High temperature & glass corrosion performance of the brick is slightly lower than that of chromium oxide, also by isostatic pressing forming method, its technical indicators ZrO2>65%, <2.0% porosity, volume density of about 4.25g/cm3, the temperature in E glass is higher than 1370 DEG C have erosion. Used in the E glass melting pool unit kiln glass temperature slightly lower at the end of the transition path, forming the bottom of the pool and forming path path flow tank and bushing support brick etc.. In addition, the dense zirconia brick is used as the backing brick of the dense chrome brick.

- Q:What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q:Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q:Ask for help about the phase of refractory material

- Secondary crystalline phase. The second phase and second phase or second phase, and the main crystal phase and is in high temperature liquid phase coexistence in refractory material, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase. There are structure of refractory refractory material in the crystal phase, especially the direct combination of high melting point and so on, the resistance to high temperature also tend to benefit. Compared with the ordinary brick, the second phase of the refractory products, make the products refractoriness under load are improved. Many according to mineral composition of refractory material named, such as mullite corundum brick, corundum mullite brick, is its main crystal phase and the second phase composite named. The former is mainly crystal phase, the latter is sub crystalline phase.

- Q:What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q:What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

- Q:What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corundum Mullite Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords